360° degree tempered glass road studs are installed within the road surface for guidance, warning and traffic control. They are

not only clearly visible in twilight and darkness, but also they ensure better visibility for the road user during the day.

Especially with backlight from the sun and/or in heavy rain, since the tiny glass beads in the thermoplastic are non-reflective in

the rainy water, 360° degree glass road studs are more visible than road markings, and this increases traffic safety

significantly. Examples of applications are turbo roundabouts, dangerous curves, driveways or highways, public squares and parking

lots. See the images above for an overview of other applications.

- Product Details

- {{item.text}}

Quick Details

-

Name:

-

glass road stud cat eye reflectors road stud road safety reflector

-

Material:

-

Tempered Optical Glass

-

Size::

-

100*50MM

-

Weight:

-

500g/piece

-

Protection Material:

-

Metallic Compound

-

Colour:

-

Yellow, Blue, Green and White

-

Retro Reflective Angle:

-

360 degree

-

Hardness:

-

170±5

-

Weathering Resistance Properties:

-

16280h

-

Turnover Attrition Rate:

-

3%

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

wistron

-

Model Number:

-

HT-RS-G1A

-

Name:

-

glass road stud cat eye reflectors road stud road safety reflector

-

Material:

-

Tempered Optical Glass

-

Size::

-

100*50MM

-

Weight:

-

500g/piece

-

Protection Material:

-

Metallic Compound

-

Colour:

-

Yellow, Blue, Green and White

-

Retro Reflective Angle:

-

360 degree

-

Hardness:

-

170±5

-

Weathering Resistance Properties:

-

16280h

-

Turnover Attrition Rate:

-

3%

Product Description

Brief Introduction

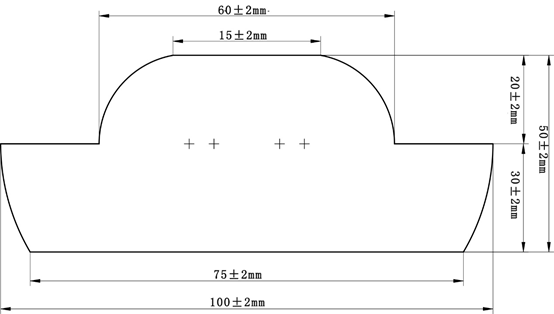

Specification

|

Name

|

360° degree tempered glass road studs

|

|

Material

|

tempered glass

|

|

Diameter

|

100mm

|

|

Height

|

50mm

|

|

Weight

|

500grams

|

|

Compression resistance

|

60 tons

|

|

Surface finish

|

paint spray or aluminum spray

|

|

Color

|

white/yellow/red/green/blue

|

Product Performance

360 degree retro-reflective, visual distance 800 meters

Waterproof:IP68

Load capacity>40tons

Feature

1. Full 360° Retro Reflective, no blind spots.

2. Highest Impact strength and compressive capacity > 60 metric tons – ensuring retained reflectivity and durability.

3. Slip proof surface.

4. The lifespan is 16 times longer than traditional plastic or aluminum pavement marker

5. Free maintenance, self-cleaning after being installed into both asphalt and concrete roads.

6. Alternative to lamppost, resistant to snow ploughs.

2. Highest Impact strength and compressive capacity > 60 metric tons – ensuring retained reflectivity and durability.

3. Slip proof surface.

4. The lifespan is 16 times longer than traditional plastic or aluminum pavement marker

5. Free maintenance, self-cleaning after being installed into both asphalt and concrete roads.

6. Alternative to lamppost, resistant to snow ploughs.

Installation Construction

1. Road safety Devices

2. Use drill stop on the drilling bit to drill hole (Diameter: 100mm, Depth: 25mm)

3. Use hammer and chisel to remove the asphalt or concrete debris in the hole.

4. Use high pressure air blower to blow away the sand and water in the holes. Or use sponge to absorb the water

5. Use depth gauge to test the proper depth of holes. Modification may required to if too deep or too shallow.

6. Use epoxy or asphalt adhesive to fasten reflector. Asphalt adhesive is suggested for installation on freeways or high traffic areas or for larger road projects,

7. Place road stud in the hole and turn about 30 degrees. Use a rubber hammer to secure the position by gently pounding the glass dome.

Hot Searches