- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

5100

-

Thickness:

-

30mm-150mm

-

Size:

-

700*450 (35-100), 1500*450 (35-100)

-

Product name:

-

Exceeded Expectations epoxy tooling board used to car model

-

Heat distortion temperature:

-

70-75

-

Density:

-

1

-

Hardness Shore:

-

78-80D

-

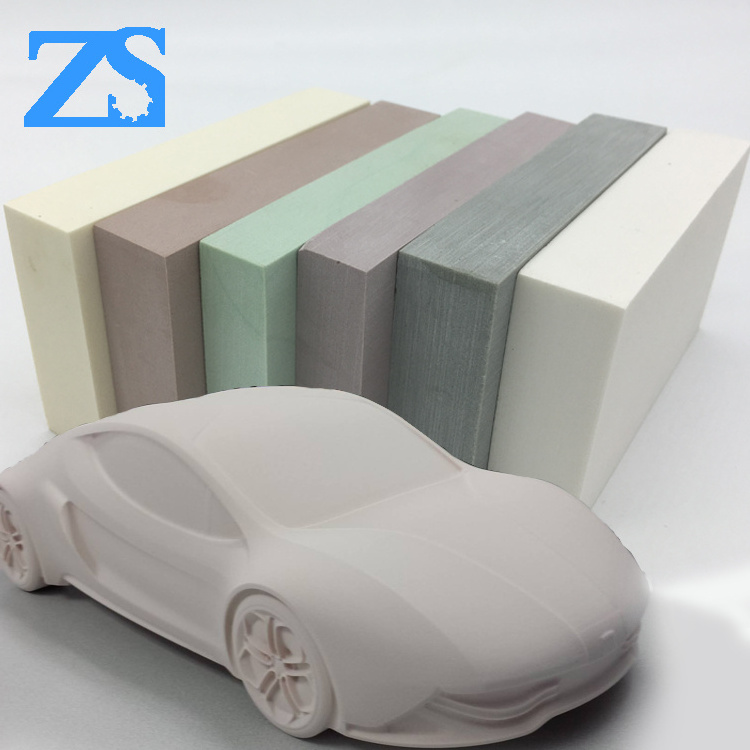

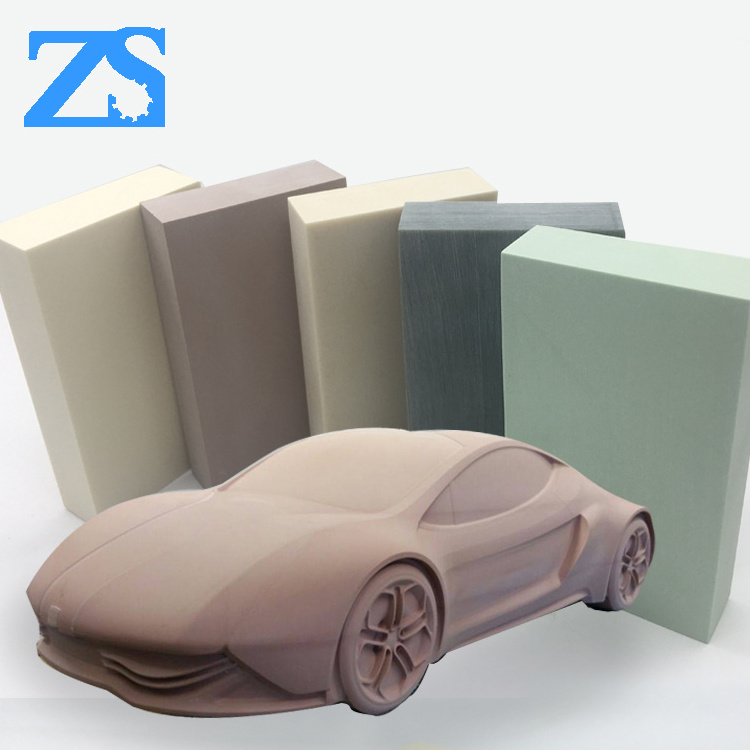

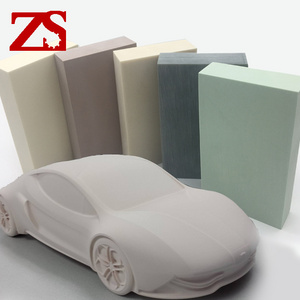

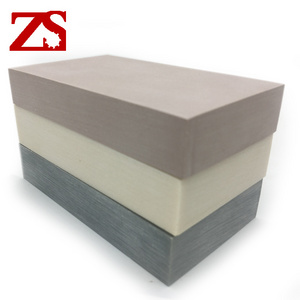

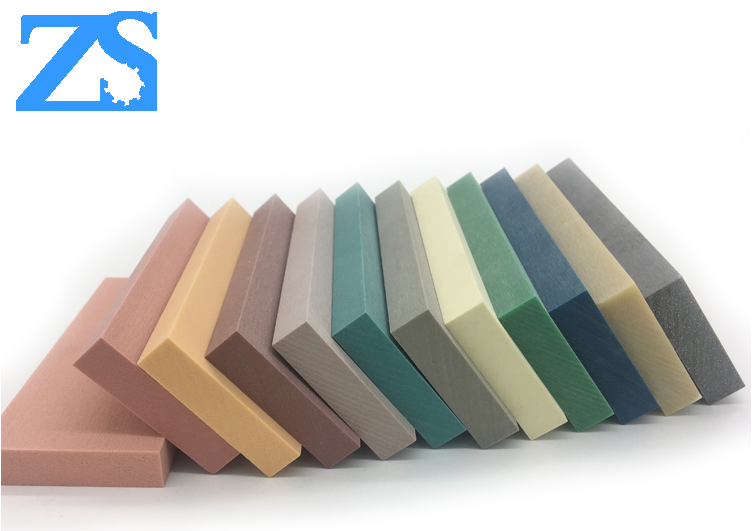

Color:

-

Beige ,Brown,white,Pink

-

Thermal expansion coefficient:

-

40-45

-

Application:

-

car mould,shoe mould,Pressure-type mold, Gage,jigs production

-

size:

-

700*450 (35-100), 1500*450 (35-100),OEM

Quick Details

-

Processing Service:

-

Cutting, Moulding

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

ZS

-

Model Number:

-

5100

-

Thickness:

-

30mm-150mm

-

Size:

-

700*450 (35-100), 1500*450 (35-100)

-

Product name:

-

Exceeded Expectations epoxy tooling board used to car model

-

Heat distortion temperature:

-

70-75

-

Density:

-

1

-

Hardness Shore:

-

78-80D

-

Color:

-

Beige ,Brown,white,Pink

-

Thermal expansion coefficient:

-

40-45

-

Application:

-

car mould,shoe mould,Pressure-type mold, Gage,jigs production

-

size:

-

700*450 (35-100), 1500*450 (35-100),OEM

Introduction

-

ZS Tooling boards take the place of wood and metal in models, patterns, molds, jigs and fixtures.

-

They are lighter and more economical than steel and aluminum. They also do not suffer from the grain and poor dimensional stability of wood.

-

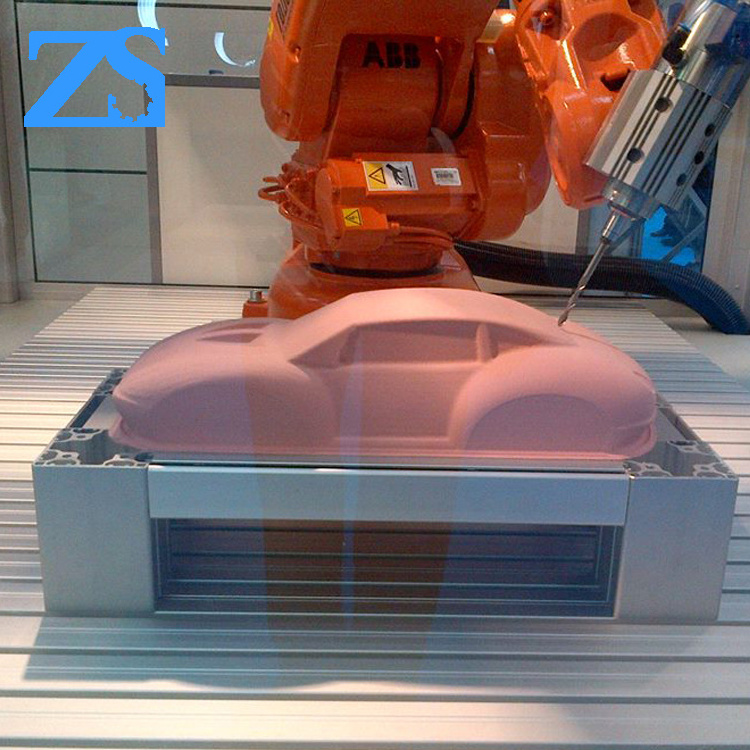

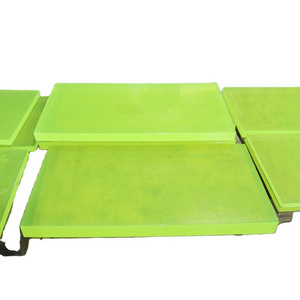

Tooling boards can be bonded together to form larger blanks and large blocks from which models or tools can be CNC-machined. The boards are easily mechanically workable with low dust formation.

-

Tooling boards are useful for creating durable, reusable tools, prototypes, models and patterns with a CNC machine for use in the motor sport and automotive industries. Selecting the most fit for purpose tooling board will reduce residual particles for easy cleanup, have excellent dimensional stability and maintain tolerances even when exposed to temperature and humidity extremes.

- Modeling board,tooling borad,epoxy tooling boards and polyurethane tooling baords are heavily used in the automotive industry as well as other industries where prototyping and modeling work is required.

Application

- Master pattern,Modling • Yacht models,wind power , craft models

-

Checking fixture,jig

•

Shoe patterns

- Automobile model • Protyping

- Vacuum forming,prepreg CF autoclave cured • Foundry,Casting

KEY PROPERTIES

- Easy workability • High dimensional stability

- Cost effective • Good compressive strength

- High Temperature and chemical resistance • Large sheet sizes available

- Smooth, non-porous surface finish • Low coefficient of thermal expansion

* Technical data sheet of tooling boards

Xiamen Zhisen Electro Equip Co.,Ltd,was found in 1997, which have been committed to research and develop polymer composite, high speed CNC equipment (with linear motor drive), model and checking fixture manufacturing.

At present ,We have several factories located in China,including ONE Composite tooling boards factory, ONE composite mineral material,ONE carbonfiber factory,ONE CNC machinery factory and TEN automatic checking fixtures related factories.

We are supporting these industries, automobiles, high-speed rail,shipbuilding, aviation, ceramics, mold, wind power and yacht,foundry industry and daily necessities manufacturing and related industrieschecking fixtures.

1. We have formed services in the aerospace, automotive, yacht and other industries of composite materials and also processing equipment industry chain company,providing composite tooling board materials, tooling board finished products(like model,checking fixtures,die etc.),5 Axis Bridge Maglev CNC machining centers to the clients all over the world.

2.We are the first factory of the first piece tooling board manufacturer in China,with R&D ability for tooling board materials to use in different application. Dimension stability can be guaranteed.

3. We are the long-term partners for each Main automotive manufacturers.

4. We developed a super CNC machine with 80M / MIN fast traverse speed, acceleration up to 1G or more, no backlash drive, machining accuracy + -0.005MM, non-contact transmission, geometric accuracy and long life, can achieve processing roughness RA0. 03μm.

5. Maglev machining center is applied into graphite mold,high precision electrode copper mold machining,specular machining,mobile phone frame arc back cover,electronic products metallic shell processing etc.

6. Maglev Gantry 5 Axis Machining Center,apply into the aerospace industry (aluminum alloy profiles,fuel tanks etc.,Cars & Yacht industry(new energy automobile and aluminum body,battery box,yacht non-metallic modeling,composite,automobile model,yacht model),Mold (Automotive stamping dies,injection mold etc.)

1. When can I get the quotation ?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

2. How can I get a sample to check your quality ?

After price confirmed,sample order is available to check our quality.

3. What is your main products ?

Linear motion systems,like lead screws, flexible coupling,Miniature linear guide rails,ball screws,linear rod shaft,ceramic bearings ...etc. But also CNC machining centers and CNC machinable tooling boards.

4. Could you get a better price on your products ?

Yes,you can.We will give the best price on all of the products you need,which can help you to compete other companies in your markets.

5. What is the strength of your company ?

We have a engineer team,who have well experienced on product's and machine designs.W e can help you to solve the problems you meet.

| ZS-TOOL High quality polyurethane tooling board HDU foam board make for car mould |