- Product Details

- {{item.text}}

Quick Details

-

Max. Spindle Speed (r.p.m):

-

4500 r.p.m

-

Max. Weight of Workpiece(kg):

-

360

-

Width of bed (mm):

-

500 mm

-

Spindle Motor Power(kW):

-

7.5

-

Max. Turned Length (mm):

-

500

-

Travel (X Axis)(mm):

-

200 mm

-

Travel (Z Axis)(mm):

-

550 mm

-

Place of Origin:

-

Hennan

-

Dimension(L*W*H):

-

2400*1800*1950

-

Brand Name:

-

Rowdai

-

Model Number:

-

TCK50

-

Voltage:

-

380V

-

Weight (KG):

-

4300

-

Keyword:

-

Slant bed CNC lathe

-

Application:

-

Indurstria metal processing

-

Turret Type:

-

NC turret or HY turret

-

Tool holder:

-

Station Hydraulic Turret

-

Power(KW):

-

7.5

-

Chuck:

-

Manual/Hydraulic

-

Control system:

-

GSK FANUCMITSUBISHI KND

-

Material Support:

-

Steel,copper, alum,inum,Iron

-

Precision:

-

0.006mm

-

CNC or Not:

-

CNC Lathe Machine

Quick Details

-

Type:

-

TURNING CENTER

-

Max. Length of Workpiece (mm):

-

500

-

Year:

-

2020

-

Max. Spindle Speed (r.p.m):

-

4500 r.p.m

-

Max. Weight of Workpiece(kg):

-

360

-

Width of bed (mm):

-

500 mm

-

Spindle Motor Power(kW):

-

7.5

-

Max. Turned Length (mm):

-

500

-

Travel (X Axis)(mm):

-

200 mm

-

Travel (Z Axis)(mm):

-

550 mm

-

Place of Origin:

-

Hennan

-

Dimension(L*W*H):

-

2400*1800*1950

-

Brand Name:

-

Rowdai

-

Model Number:

-

TCK50

-

Voltage:

-

380V

-

Weight (KG):

-

4300

-

Keyword:

-

Slant bed CNC lathe

-

Application:

-

Indurstria metal processing

-

Turret Type:

-

NC turret or HY turret

-

Tool holder:

-

Station Hydraulic Turret

-

Power(KW):

-

7.5

-

Chuck:

-

Manual/Hydraulic

-

Control system:

-

GSK FANUCMITSUBISHI KND

-

Material Support:

-

Steel,copper, alum,inum,Iron

-

Precision:

-

0.006mm

-

CNC or Not:

-

CNC Lathe Machine

TCK56 High precision slant bed lathe Tck50 TCK60 High Rigidity CNC Metal Turning Milling Machine Inclined Lathe

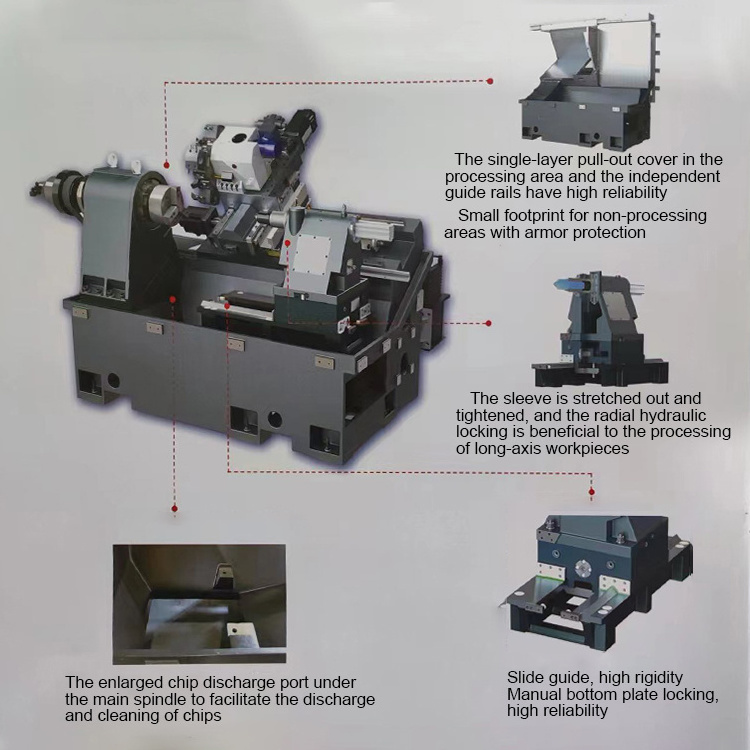

Feature

1.High precision CNC slant bed lathe ,Taiwan screw & linear guideway can be optional.

2.The Cartridge spindle type with high precision,it can ensure the rigidity and precision.

3.High precision grade ball screw ensure positioning accuracy more stable.

4.GSK,Siemens, Fanus, Mistsubishi, KND controller as optional.

Whole bed body adopt Monoblock cast iron way, ensure high rigidity.

| Machine Model | Unit | TCK-50A | TCK-56A | TCK-66A |

| The maximum turning diameter on the bed | mm | φ500 | φ560 | φ660 |

| The maximum turning diameter on the slide | mm | 240 | φ330 | φ500 |

| cutting length | mm | 500 | 500/750/1000 | 750/1000/1500 |

| Spindle end type and code | A2-6 | A2-6 | A2-11 optional A2-8 | |

| Spindle through hole diameter | mm | φ66 | φ66 | φ86 / φ112 |

| Chuck | inch | 8 inch hydraulic hollow chuck | 10 inch hydraulic hollow chuck optional 8 inch | Hollow 15 inches optional 10 inches 12 inches |

| Spindle speed range | r/min | 3500 | 3500rpm | 2800rmin |

| main motor power | KW | 7.5kw | 11kw /15kw | 22KW |

| X-axis rapid traverse speed | m/min | 20 | 20 | 16 |

| Z-axis rapid movement speed | m/min | 20 | 16 | 16 |

| X-axis travel | mm | 210 | 250 | 380 |

| Z axis travel | mm | 450 | 600/860 | 600/850/1350/ |

| Rail form | Taiwan HIWIN/PMI rail | Taiwan HIWIN/PMI rail | Taiwan HIWIN/PMI rail | |

| Tool holder form | 8-station servo turret | 8-station servo turret (optional 12-station) | 12-station servo turret | |

| Tool size | mm | 25X25 φ32 | 25X25 φ40 | 32*32 φ40 |

| Tailstock sleeve diameter/stroke | mm | φ75/L100 | φ110/L100 | φ150/L150 |

| Tailstock sleeve taper | MT4 | MT4 | MT-5 | |

| Positioning accuracy X/Z | mm | 0.01/0.01 | 0.01/0.012 | 0.01/0.018 |

| Repeat positioning accuracy X/Z | mm | 0.006/0.006 | 0.006/0.008 | 0.008/0.010 |

| Precision | level | IT6 | IT6 | IT6 |

| roughness | um | Ra≤0.6 | Ra≤1.6 | Ra≤1.6 |

| Machine Tool Dimensions | mm | 2800x1800x1600 | 2900/3100/4300x2000x2000 | 3450/3700/4200*2200*2200 |

| Machine weight | kg | 3000 | 3600/4000/5000 | 5000/5800/6800 |

Henan Rowdai Machinery Equipment Co. td . is a manufacturer dedicated to the producion of machine tools and specializing in the production of vertical machining centers, double column machining centers, CNC milling machines, CNC slant-bed lathes CNC flat-bed lathes, turning centers,and other CNC equipment in China.

We insist that customer's success is our success, insist on providing customers with excellent products and professional services, develop into an excellent atractive machine tool equipment supplier in China.

Our manufacturing and supply source