- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

shangda, shangda

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

1850*1050*1800MM

-

Motor Power (Kw):

-

160kw

-

Power (kW):

-

90-550kw

-

Weight (KG):

-

14000 KG

-

Product name:

-

small capacity disk wood pellet processing making machinery

-

Power:

-

160kw

-

Dimension:

-

1850*1050*1800MM

-

Weight:

-

14000kg

Quick Details

-

Pellet Diameter (mm):

-

8 - 12

-

Output (kg/h):

-

1000 - 6000 kg/h

-

Place of Origin:

-

Shandong, China, Shandong, China (Mainland)

-

Brand Name:

-

shangda, shangda

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

1850*1050*1800MM

-

Motor Power (Kw):

-

160kw

-

Power (kW):

-

90-550kw

-

Weight (KG):

-

14000 KG

-

Product name:

-

small capacity disk wood pellet processing making machinery

-

Power:

-

160kw

-

Dimension:

-

1850*1050*1800MM

-

Weight:

-

14000kg

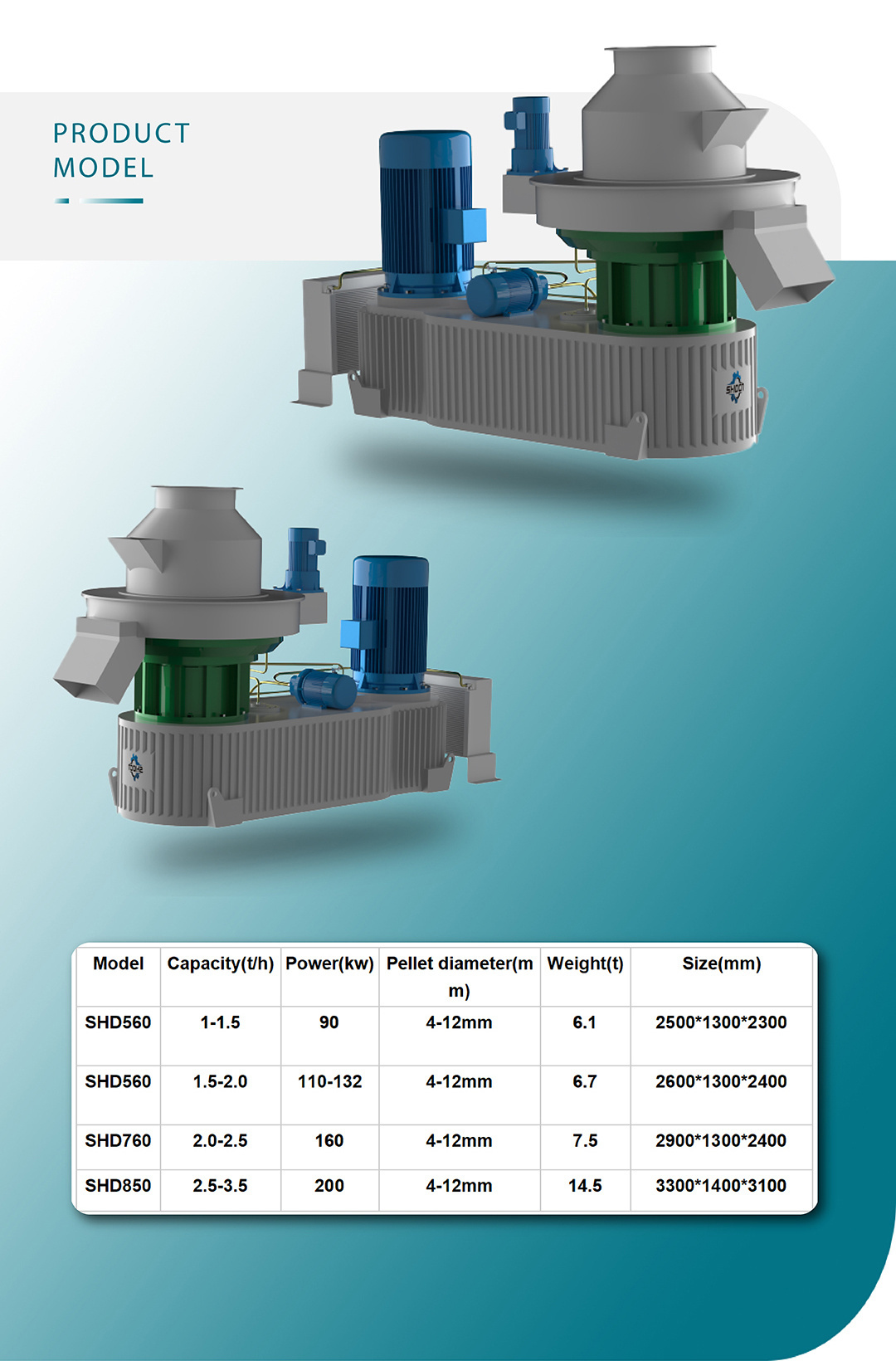

Product Description

The pellets mill is applied to the material with low adhesiveness and low shaping such as the rice husk, sunflower seed husk, peanut shell and other fruit shell branch, trunk, bark, crop straws, rubber, cement ,ash and other chemical materials. The pellet mill is widely used in the feed plant, wood processing, fuel plant, fertilizer plant and chemical plant etc. It is the ideal pressing shaping equipment with low investment and high profit.

SHDwood pellet mill has been successufully applied to the wood pellets production from pinus sylvestris sawdust and other wood scraps/chips/sawdust

SHDwood pellet mill has been successufully applied to the wood pellets production from pinus sylvestris sawdust and other wood scraps/chips/sawdust

Specification

Details Images

Production Process

1. Use Wood Chipper. Wood Crusher, Hammer mill to make wood logs, chips (or other materials) smaller

2. Use Dryer (rotary drum dryer I Air-flow dryer) or add water to the sawdust(or other materials) till its moisture content between 12-15%, which is the best moisture content for pelletizing.

3. Put the sawdust into the pellet machine gradually. Large scale pellet production need a

screw feeder to make sure stable feeding of raw material

screw feeder to make sure stable feeding of raw material

4 After pelletized, the pellets are of high temperature that is not suitable for direct packing. So they should be cooled by pellet cooler.Then, pellets go through a vibrating sieve, where good pellets will be left, while broken ones or powder will be collected for reproduction.

5. After all the above procedures. pellets can be packed with a pellet packing machine

Customer Case

Our pellet machines and pellet production lines have our machines in Malaysia, Thailand, Russia, Turkey, etc.

Hot Searches