QTILES, IBR & CORRUGATED ROOF SHEETS

Machine types : Automatic C purlin forming machine sandwich panel production line

corrugated roof sheet making machine

glazed tile making roll forming machine

Angle Chi roll forming machine

steel deck machine

Ridge tile machine

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.20-0.50MM

-

Place of Origin:

-

Hebei, China

-

Voltage:

-

380v 50Hz

-

Weight:

-

3800 kg

-

Feeding width:

-

800-1250MM

-

Product name:

-

roof tile roll forming machine

-

Usage:

-

corrugated roofing sheet roll forming machine

-

Payment:

-

TT LC

-

Shaft material:

-

45# High Grade Steel

-

Suitable material:

-

Q235 Galvanized Steel Coil

-

Roller material:

-

GCr15

-

After Warranty Service:

-

Online support

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

8-10m/min

-

Rolling thinckness:

-

0.20-0.50MM

-

Place of Origin:

-

Hebei, China

-

Voltage:

-

380v 50Hz

-

Weight:

-

3800 kg

-

Feeding width:

-

800-1250MM

-

Product name:

-

roof tile roll forming machine

-

Usage:

-

corrugated roofing sheet roll forming machine

-

Payment:

-

TT LC

-

Shaft material:

-

45# High Grade Steel

-

Suitable material:

-

Q235 Galvanized Steel Coil

-

Roller material:

-

GCr15

-

After Warranty Service:

-

Online support

Product Description

Specification

|

1

|

Suitable material

|

Color steel sheet , galvanized steel sheet,aluminum sheet

|

|

2

|

Installation Dimension (L*W*H):

|

6.5m*1.5m*1.4m(depend on design)IBR Roof Sheet Making Machine

|

|

3

|

Main motor power

|

3KW ~4KW with Cycloidal reducer

|

|

4

|

Hydraulic station power

|

3KW ~4KW

|

|

5

|

Hydraulic oil pump

|

CB-E 310

|

|

6

|

Thickness of material

|

0.2mm~0.8mm

|

|

7

|

Diameter of principal axis

|

Φ70-90mm

|

|

8

|

Material expand width

|

1000,1200,1250mm

|

|

9

|

Electric tension

|

380V 3phase 50HZ or as the customer's requirements

|

|

10

|

Material of roller

|

High grade 45# forged steel plated with hard chrome plating

|

|

11

|

Controlling system

|

PLC

|

|

12

|

Processing speed

|

3-6m/min

|

|

13

|

Processing precision within

|

1.00mm (depend on design)

|

|

14

|

Material of cutting blade

|

Cr12 mould steel with quenched treatment

|

|

15

|

Kind of drive

|

0.6 inch chain link bearing model 6210

|

|

16

|

Roller station

|

8-20 Rollers

|

|

17

|

Roller material

|

high grade 45#steel; Cr12 quenching

|

|

18

|

Leak frame load-bearing

|

4.6T

|

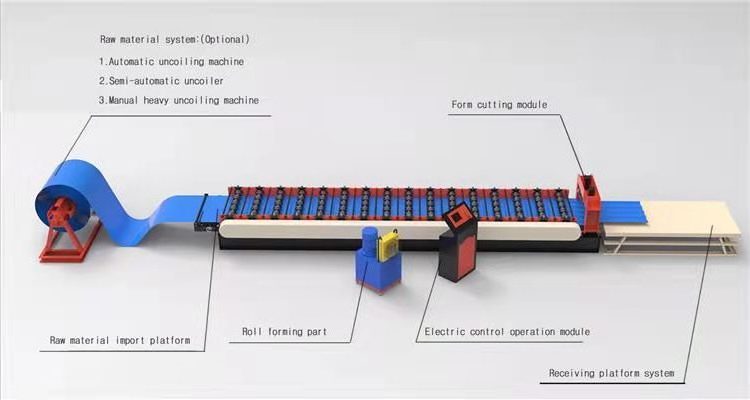

DECOILER

1. Uncoil Type: Hydraulic loosen and tension, Electric uncoiling

2. .Maximum capacity: 5 Ton

3. I.D: 460-508mm; O.D: 1350mm

4. Structure: Steel plate and beam welded

5. Function: Supporting and uncoiling the steel coils

2. .Maximum capacity: 5 Ton

3. I.D: 460-508mm; O.D: 1350mm

4. Structure: Steel plate and beam welded

5. Function: Supporting and uncoiling the steel coils

FEEDING PLATFORM WITH PRE-CUTTER

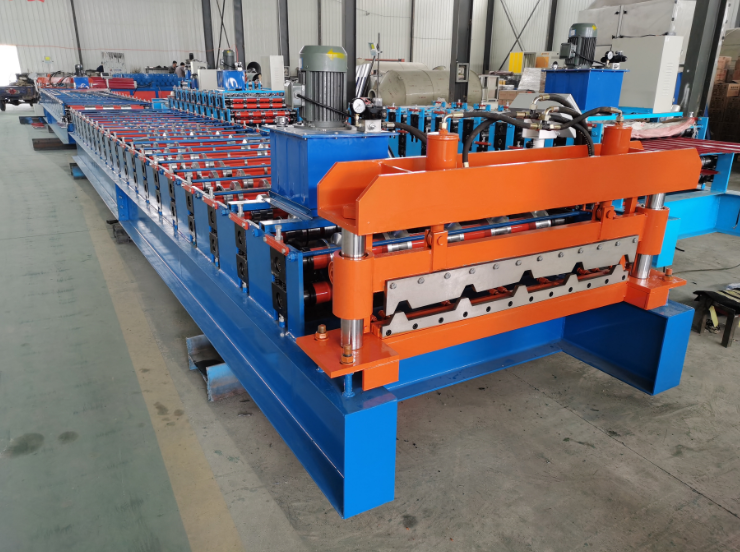

ROLL FORMING MILLS

1. Machine base frame adopt 450mm H beam and chromed roll forming stands

2. Roll station: 18 forming steps

3. Roller material: ASTM 1045 steel chrome plated surface with hardness 58-62 degree ,CNC,

4. Side Roller Material: ASTM 1045, chromed 0.05mm.

2. Roll station: 18 forming steps

3. Roller material: ASTM 1045 steel chrome plated surface with hardness 58-62 degree ,CNC,

4. Side Roller Material: ASTM 1045, chromed 0.05mm.

Packing & Delivery

roof tile roll forming machine

standard wooden case for export

20ft container or 40ft container

Hot Searches