- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

>= 98%

-

Voltage:

-

380/220V

-

Place of Origin:

-

China

-

Weight:

-

2000 KG

-

Function:

-

Washing Filling Capping

-

Usage:

-

Powder Products

-

Bottle type:

-

PET Plastic Glass Bottle

-

Capacity:

-

3600-4800BPH

-

Advantage:

-

High Effiency

-

Filling volume:

-

1-100g

-

Control:

-

Siemens PLC+ Touch Screen

-

Filling nozzles:

-

2 Nozzles

-

Material:

-

Stainless Steel 304/316

-

After Warranty Service:

-

1 Year Spare Parts

Quick Details

-

Machinery Capacity:

-

3600-4800BPH

-

Packaging Material:

-

Plastic, Paper, Metal, Glass, Wood

-

Filling Material:

-

Powder

-

Filling Accuracy:

-

>= 98%

-

Voltage:

-

380/220V

-

Place of Origin:

-

China

-

Weight:

-

2000 KG

-

Function:

-

Washing Filling Capping

-

Usage:

-

Powder Products

-

Bottle type:

-

PET Plastic Glass Bottle

-

Capacity:

-

3600-4800BPH

-

Advantage:

-

High Effiency

-

Filling volume:

-

1-100g

-

Control:

-

Siemens PLC+ Touch Screen

-

Filling nozzles:

-

2 Nozzles

-

Material:

-

Stainless Steel 304/316

-

After Warranty Service:

-

1 Year Spare Parts

Product Description

This machine is a washing, drying and filling unit for ampoule and vial powder, which is mainly used for washing, drying, screw filling, capping and sealing of vials such as 2-20ml ampoule and vial. It adopts disc type clamping bottle washing machine, screw bottle feeding, two water and one gas rinsing, and is sent into the oven through screw or dial mechanism, hot air circulation drying, and the dispenser adopts screw dispensing, servo motor driven metering, high-precision servo motor controlling dial for positioning, and the servo drive of the powder, precision cooperation, the whole machine is reasonable in design, reliable and stable in operation, simple in operation, high in automation degree, and easy to dismantle and wash, which is in full compliance with the requirements of GMP specification. GMP specification requirements.

Technical Parameter

|

Model No.

|

MIC-PV80

|

|

Capacity

|

60-80 bottles/min

|

|

Power

|

35.0KW

|

|

Power supply

|

380V 60HZ

|

|

Filling precision

|

≥98%

|

|

Dimension

|

11500×1600×2000mm

|

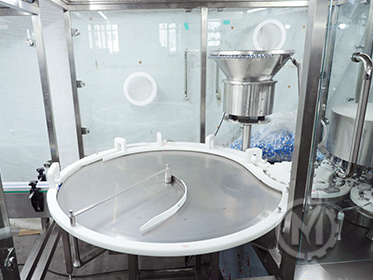

Washing bottle turn cage

Empty bottles enter the turn cage, washing method water. The size is customized according to your bottle

Double head for filling powder

Suitable for 1-10ml vial bottle,Screw unloading.

Inner plug staion

Inner rubber plug vibrating plate, sort out inner plug automatically and send inner plug send to loading plug guide in turn .Loading inner rubber plug guide ,connect with loading plug station, vibrating plate sort out plug and send plug to the loading plug station through the load plug guide continuously.

Cap loading tunnel

Connect with capping station, when the Cap is arrangement in the guide in turn, cap will through guide send to capping station in turn, after put cap above the inner plug, bottle will into next station to screw cap.

Screw capping station

Rotate wheels structure design will make the machine running more stable. Reasonable structure, can extend the life of the machine. All of connecting parts are rotate wheels structure or screw bolt tighten. It is easy for customers to change spare-parts for different size bottle.

PLC touch screen

All operate control by touch screen panel . Such as filling speed and volume, capping speed. Also, the machine is no bottle no filling.

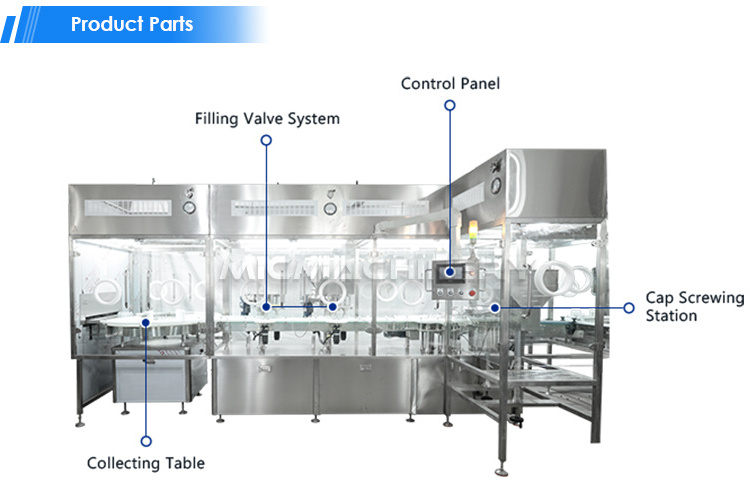

Product Detail

Empty Bucket Infeed Conveyor System

Manually put the empty bucket & canister on the infeed conveyor station

Collecting table

collected bottle from washing machine

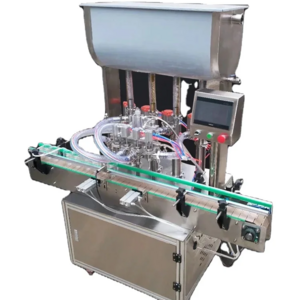

Filling Valve System

The servo motor will drive the filling nozzle goes up and down, in order to start the filling at the bucket's bottom side to reduce the foams causing. At the same time, each filling nozzle equipped with return suction function, even if there are some foams caused, our filling nozzle still can suck the foams into the small storage container. In order to prevent the liquid overflow from the bucket mouth.

Mould

bottle size make customized

Vibration disk for inner rubber plug

Inner rubber plug vibrating plate, sort out inner plug automatically and send inner plug send to loading plug guide in turn.

Vibration disk for outside cap:

The vibrating plate used to sort out the outside cap , sending cap to capping station through loading cap guide in turn.

Ooutput

Related Products

FAQ

Q1.Are you trading company or manufacturer ?

>>

We are factory. Our factory is located in Zhangjiagang near Shanghai.

Q2.What is the payment of your company?

>>

100% T/T, 30% of prepaid contracts entered into force, 70% paid before delivery. L/C is supported also.

Q3.Do you provide a complete production line and customized services?

>>

We are a company that provides a complete production line. We can design the machine according to your requirements (material, power, filling type, bottle type, etc), and we will give you our professional advice. As you know, we have beenin this industry for many years.

Q4.If we buy your machine, what is your guarantee or quality assurance?

>>

We provide you with high- quality machines with 1 year warranty and lifetime technical support.

Q5.How long does it take to install?

>>

According to your machine order, we will send one or two engineers to your factory, about 10 days. Customers need to provide round-trip air tickets, visa fees, local transportation, accommodation, food, 120 US dollars/ day / person.

Q6.What kind of after-sales service is provided?

>>

After the production is completed, we will debug the production line, take photos, video and send to customers via email or instant tools. After the commissioning is completed, we will package and ship the equipment according to the standard export packaging. Operating manuals will be sent with machine or by email. According to the customer' s requirements, we can arrange our engineers to the customer's factory for installation and training. Engineers, sales managers, and after-sa les service managers form an after-sales team to follow up on customer projects online and offline.

Hot Searches