- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

china

-

Voltage:

-

customized

-

Power:

-

customized, 7-9.5kw

-

Weight:

-

500 kg

-

Material:

-

expand polystyrene

-

Color:

-

customized

-

block length:

-

2 - 8 meter

-

Type:

-

air cooling type

-

Advantage:

-

high capacity

-

Keywords:

-

EPS block machine

-

Function:

-

Making EPS block

-

Product Size::

-

4000

-

Feature:

-

produce eps panel

Quick Details

-

Marketing Type:

-

New Product

-

Production Capacity:

-

customized

-

Place of Origin:

-

China

-

Brand Name:

-

china

-

Voltage:

-

customized

-

Power:

-

customized, 7-9.5kw

-

Weight:

-

500 kg

-

Material:

-

expand polystyrene

-

Color:

-

customized

-

block length:

-

2 - 8 meter

-

Type:

-

air cooling type

-

Advantage:

-

high capacity

-

Keywords:

-

EPS block machine

-

Function:

-

Making EPS block

-

Product Size::

-

4000

-

Feature:

-

produce eps panel

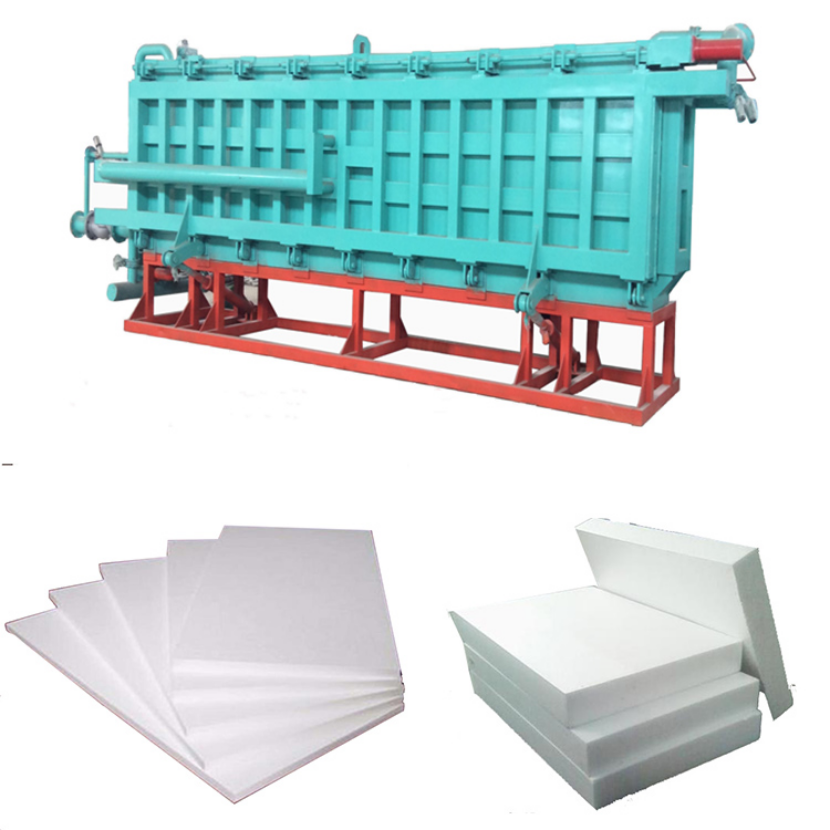

EPS block production line

eps foam block machine

Product Description

Specification

EPS Block Production Line

1. EPS block production line feature:With the use of PLC Controller(Programmable Logic Controller)and Touch Screen, the cycle process of opening and closing of the mould, material feeding, steaming, temperature preservation, cooling, mold ejection, and releasing the final product from the machine will be accomplished automatically.

2. EPS block production line feature: This machine applies advanced EPS heat penetration process and optimized structure of pipelines together, fast forming, low consumption of steam, low moisture content, which make same high quality interior and exterior.

3. EPS block production line feature: Most of the main components are of world-famous brand,Adopts PLC(Japan Mitsubishi) and touch screen (French Schneider) ,and reliable design makes the operation and production simpler and fault rate lower.

4. EPS block production line feature: This machine applies hydraulic pressure transmission. Control system using differential control to control the velocity for the mould opening and closing.To ensure machine reliable performance, long working life and low maintenance cost.

5. EPS block production line feature: The machine is coupled by using high quality welding method, which is subjected to aging treatment and heat treatment, to ensure the machine has high strength, without deformatio expanded eps panel equipment n and possibility of withstand the expansion.

Top Quality Famous Brand eps insulated panel making machine for building eps block styrofoam equipment for construction

|

EPS Block Production Line Technical Parameter

|

|

|

|

|

|

|||||

|

Items

|

Unit

|

PSB-2000

|

PSB-3000

|

PSB-4000

|

PSB-6000

|

|||||

|

Mold Size

|

mm

|

2040*1020*530

|

3060*1240*630

|

4080*1240*630

|

6100*1240*630

|

|||||

|

Block Size

|

mm

|

2000*1000*500

|

3000*1200*600

|

4000*1200*600

|

6000*1200*600

|

|||||

|

Density Range

|

kg/m3

|

5-33

|

5-33

|

5-33

|

5-33

|

|||||

|

Capacity

15kg/m3

|

min/cycle

|

12

|

15

|

18

|

18

|

|||||

|

Steam

|

kg/cycle

|

20-25

|

25-35

|

40-50

|

55-65

|

|||||

|

Air compressed

|

m3/cycle

|

0.6-0.8

|

0.6-0.8

|

0.8-1.0

|

1.0-1.2

|

|||||

|

Power Connected

|

kw

|

7

|

8

|

9.5

|

9.5

|

|||||

|

Voltage

|

v

|

380

|

380

|

380

|

380

|

|||||

|

Weight

|

kg

|

3000

|

4600

|

6000

|

9600

|

|||||

EPS Pre-expander Machine

EPS material

Hot Searches