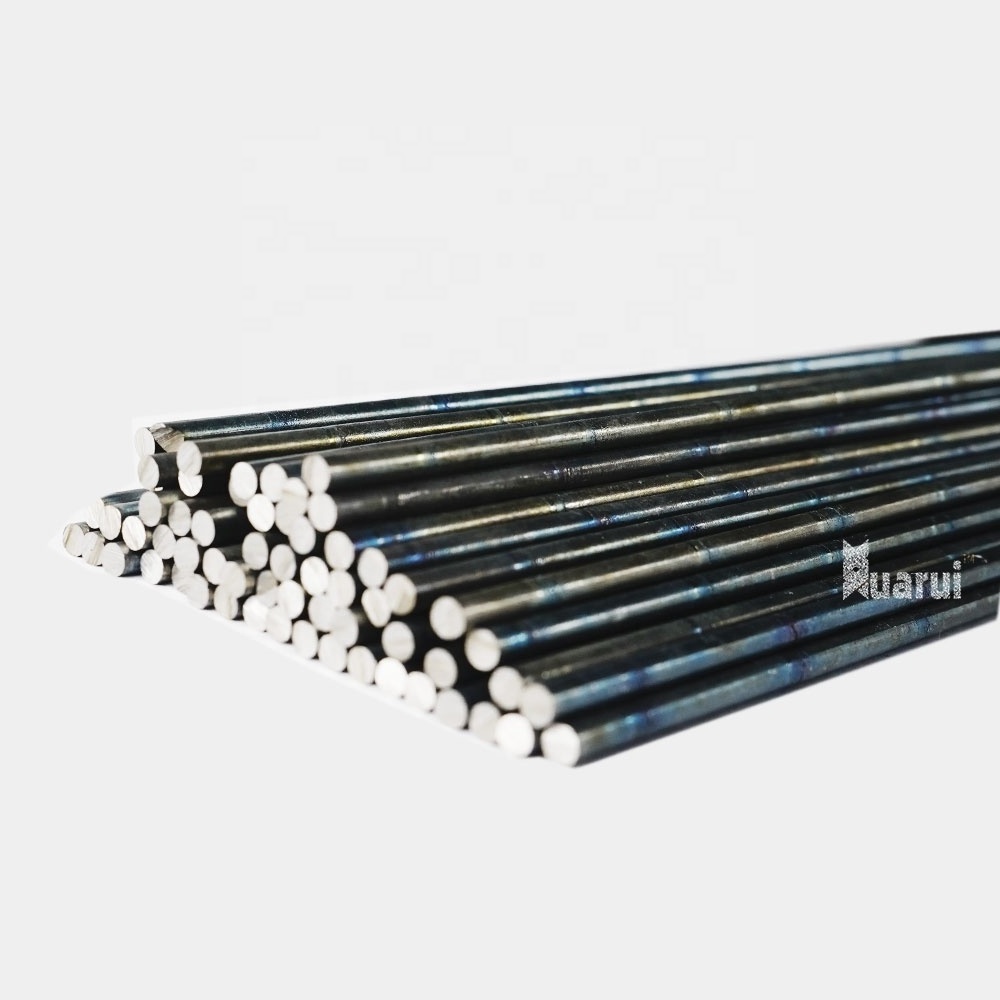

ECoCr-A is a cobalt based electrode depositing a weld metal having 28Cr-5W-1C. The weld metal possesses excellent resistance to

oxidation, impact, corrosion and heat. Its applications include overlay, surfacing applications which require heat resistance,

oxidation resistance in combination with impact and mild abrasion.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

HR-CO6-BR2

-

Shape:

-

Bar/wire

-

Material:

-

Cobalt

-

Chemical Composition:

-

Co.Cr.W.Ni.Mo

-

Product name:

-

Polystel 6 Rod consumibles tig ERCCoCr-A Welding Rod

-

Brand Name::

-

HUARUI

-

Application::

-

TIG welding

-

Shape::

-

rod

-

Chemical Composition::

-

Cobalt

-

Product name::

-

Cobalt rod

-

Other names::

-

Welding rod

-

Diameter::

-

2.7/3.2/4.0mm

-

Length::

-

350mm; 500mm; 1000mm & 2000mm

Quick Details

-

Application:

-

welding material

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

huarui

-

Model Number:

-

HR-CO6-BR2

-

Shape:

-

Bar/wire

-

Material:

-

Cobalt

-

Chemical Composition:

-

Co.Cr.W.Ni.Mo

-

Product name:

-

Polystel 6 Rod consumibles tig ERCCoCr-A Welding Rod

-

Brand Name::

-

HUARUI

-

Application::

-

TIG welding

-

Shape::

-

rod

-

Chemical Composition::

-

Cobalt

-

Product name::

-

Cobalt rod

-

Other names::

-

Welding rod

-

Diameter::

-

2.7/3.2/4.0mm

-

Length::

-

350mm; 500mm; 1000mm & 2000mm

Product Description

Polystel 6 Rods ERCCoCr-A Bishilite (MHA) Cobalt Welding Rod For Hardfacing / Wear-resistant HRCO

Process

:

TIG / MIG /

OAW / ERW / Automatic

Equivalent:

Stellite , BISHILITE (MHA) , Weartech WT, Stoodite , POLYSTEL

Application:

Hardfacing & Wear-resistant Welding

ECoCr-A

ECoCr-B

The weld metal possesses excellent resistance to oxidation, impact, corrosion and heat. Its application includes hard surfacing of

valve seats, forging dyes, crushers, hummer edges, cutting knives and blowers etc.

valve seats, forging dyes, crushers, hummer edges, cutting knives and blowers etc.

ECoCr-C

The weld metal possesses excellent resistance to oxidation, impact, corrosion and heat. Its applications include hard surfacing of

valve heads, sealing rings of high pressure pumps and parts of crusher etc.

valve heads, sealing rings of high pressure pumps and parts of crusher etc.

|

Application and Advantage for cobalt base rod

|

|

|

|

|

|

|||||

|

Grade / Standard

|

Hardness

|

wear-resistant

|

corrosion-resistant

|

workable℃

|

Application example

|

|||||

|

Stelit 6

AWS A5.21:2001 ERCoCr-A jis df-cocra |

HRC40-46

|

√

|

√

|

800℃

|

Internal combustion engine valve,

High temperature and high pressure valve, Hot shear blade, Hot forging die Overlay welding of inner and outer rings of bearings |

|||||

|

Stelit 12

AWS A5.21:2001 ERCoCr-B jis df-cocrb |

HRC46-51

|

√

|

√

|

800℃

|

Used for high temperature and high pressure valves,

Internal combustion engine valve, Various blades in the chemical industry, Shaft sleeve of high-pressure pump, Wood sawtooth, Hot-rolled finishing roll pass roller, Screw putter |

|||||

|

Stelit 1

AWS ECoCr-C JIS DF-CoCrC |

HRC≥53

|

√

|

|

650℃

|

Roller cone bit bearings,

Boiler rotating impeller, Crusher blade, Overlay welding of worn parts |

|||||

|

Stelit 4

GB/TEDCoCr-D-03 JIS DF-CoCrC |

HRC28-35

|

|

√

|

800℃

|

hot forging die

valve sealing surface |

|||||

|

Stelit 21

AWS A5.21:2001 ERCoCr-B jis df-cocrb |

HRC23

|

√

|

√

|

800℃

|

fuild valve,

brass casting die , vlave seat |

|||||

Microstructure of welding surface

Stelit 1 Stelit 6

Stelit 12 Stelit 21

Welcom to require the latest price and COA & free sample for Test

PS:

We also offer customized services

Applications

Part of Application

welding

used for Tig

Quality control system

The reason why HAURUI stand here form Year-2009

Benfits from the strict quality management system.

Huarui has the privilege of being recognized by a number of industry and customer awards for design, quality, and service over ten years.

Our services

Recommend Products

Hot Searches