- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

24V

-

Current:

-

120~300A

-

Dimensions:

-

Standard size

-

Usage:

-

Tank construction machinery

-

Product name:

-

Tank welding tractor

-

Application:

-

Tank construction

-

Function:

-

Seam welding

-

Feature:

-

High Efficiency Automatic Welding Robot

-

Welding Material:

-

Stainless Steel Carbon Steel Metal

-

Color:

-

Black

-

Welding Speed:

-

50~1250mm/min

-

Power supply:

-

DC 24V

-

Driving:

-

Driving of chain gear

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

WINCOO

-

Weight (KG):

-

8.4

-

Voltage:

-

24V

-

Current:

-

120~300A

-

Dimensions:

-

Standard size

-

Usage:

-

Tank construction machinery

-

Product name:

-

Tank welding tractor

-

Application:

-

Tank construction

-

Function:

-

Seam welding

-

Feature:

-

High Efficiency Automatic Welding Robot

-

Welding Material:

-

Stainless Steel Carbon Steel Metal

-

Color:

-

Black

-

Welding Speed:

-

50~1250mm/min

-

Power supply:

-

DC 24V

-

Driving:

-

Driving of chain gear

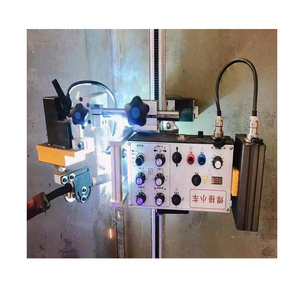

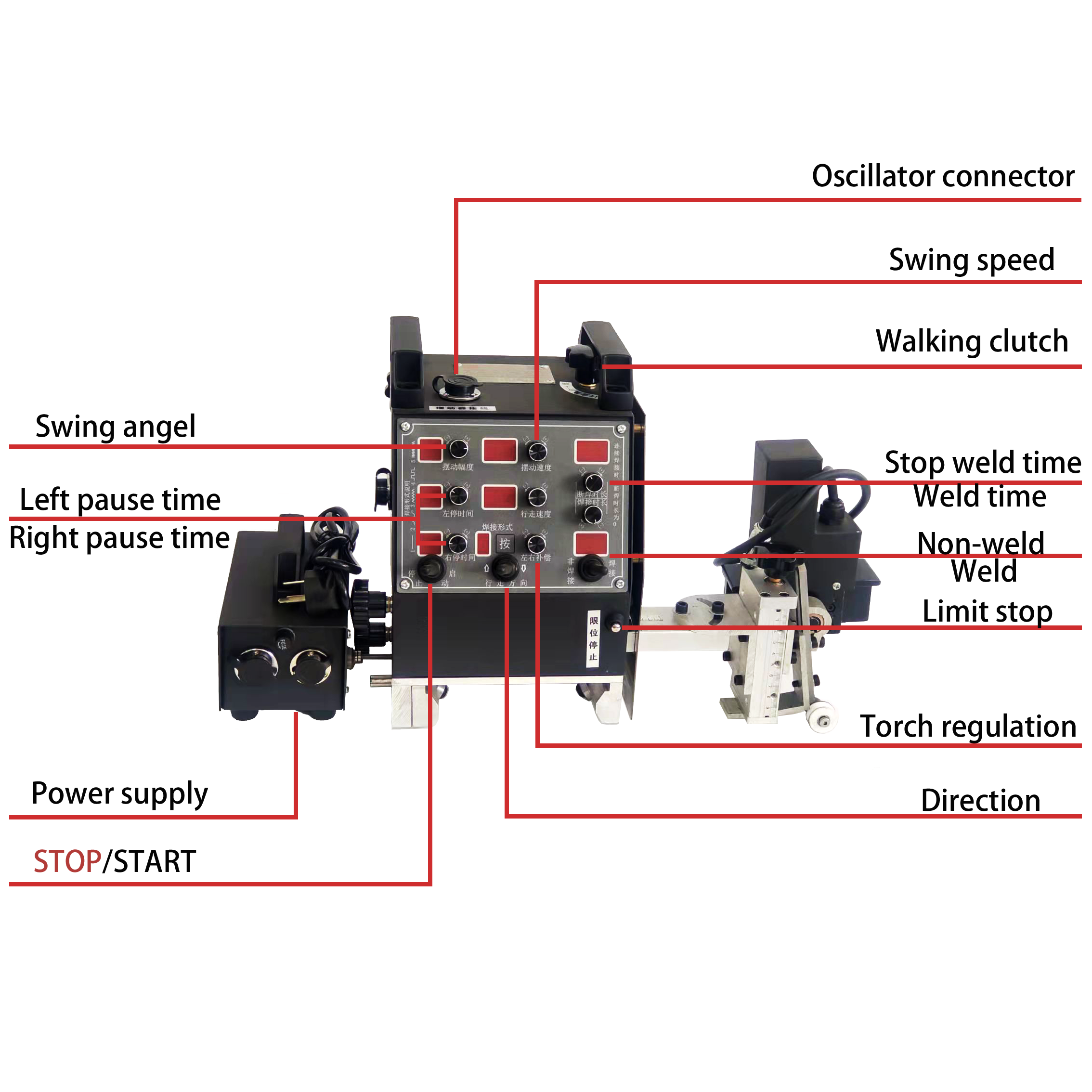

PRODUCT OVERVIEW

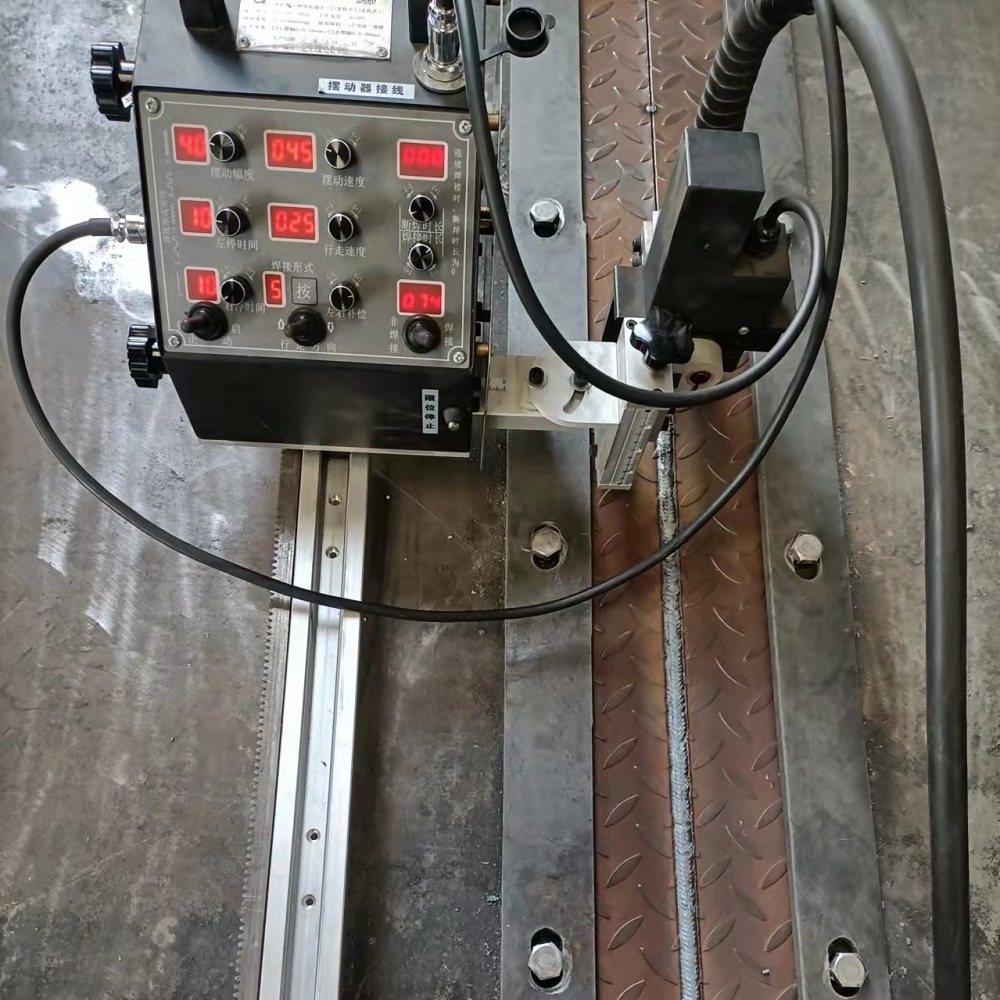

TECHNICAL PARAMETER

|

Items

|

Parameter

|

|

Notes

|

|

|

|

Straight rail type

|

Soft rail type

|

|

|

|

External power source

|

AC 220V 50/60 Hz

|

|

Three-hole

|

|

|

Working power source

|

AC 20V

|

|

Use of each driver

|

|

|

Dimensions

|

245*520*280cm

|

245*520*290cm

|

Length*width*height

|

|

|

Weight

|

8.6 kg

|

10.4 kg

|

Main host

|

|

|

Track type

|

Linear motion guide

|

Self-aligning flexible slide rails

|

|

|

|

Drive mode

|

Gear drive

|

Sprocket drive

|

|

|

|

Welding speed

|

0~1650mm/min

|

|

Fastest

|

|

|

The thinnest adsorption plate thickness

|

3mm

|

|

Magnetically attractive metal

|

|

|

Welding gun adjustment range

|

65mm

|

|

Inching for up and down

|

|

|

|

80mm

|

|

Inching for left and right

|

|

|

|

+ -60°

|

|

Swinging angle

|

|

|

|

+ -25°

|

|

Marching Angle

|

|

|

|

Stop left, stop right

|

|

Swinging form

|

|

|

Operating function

|

0-100mm/min

|

|

Swinging speed

|

|

|

|

0-2.5s

|

|

Left and right residence time

|

|

|

|

+-14mm

|

|

Swinging width

|

|

|

|

+-5mm

|

|

Center for compensation

|

|

DETAILED DESCRIPTION

A simple, inexpensive and easy to use straight or flexible rail welder for tank welding.

This machine has the following features:

This machine has the following features:

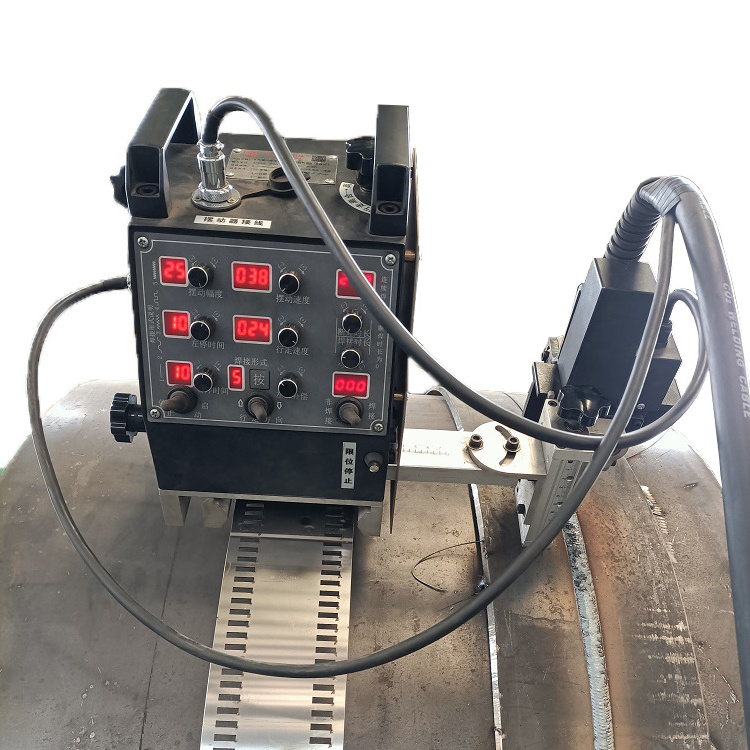

I. Product welding features

1, Equipped with 5 kinds of welding handling techniques, perfect simulation of manual handling, uniform appearance of welding seam,faster and more stable.

1, Equipped with 5 kinds of welding handling techniques, perfect simulation of manual handling, uniform appearance of welding seam,faster and more stable.

2, Weld width 0-30 mm wide range adjustment, can adapt to all kinds of thin plate, thick plate welding.

3, Weld width 0-30 mm wide range adjustment, can adapt to all kinds of thin plate, thick plate welding.

4, The machine can realize all kinds of distance discontinuous welding, length and speed can be adjusted at will.

5, The machine can demonstrate welding trajectory without ignition, convenient and intuitive.

6, Control panel is full digital display, easy to adjust and record data, with memory function, automatic recovery of the last data when the next us e.

7, Automatic stop after welding, limited stop contact is set in the two running directions of the machine, contact point is placed at the end of the weld in advance, automatic stop at the point to prevent over-welding.

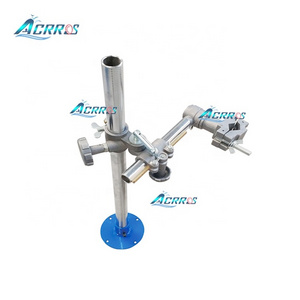

II. Product designed features

1, The sliding track of the machine adopts the linear track specially used for advanced machine tools, which has zero clearance operation, smooth running, no stuck, no deformation, and higher integrity of the machine.

II. Product designed features

1, The sliding track of the machine adopts the linear track specially used for advanced machine tools, which has zero clearance operation, smooth running, no stuck, no deformation, and higher integrity of the machine.

2, All directions of the machine are adjusted by high precision screw pitch, faster, more stable and more accurate.

3, All the parts are processed by advanced CNC machine tools, which greatly improve the accuracy and durability.

4, The whole high temperature spraying process + aluminum oxidation, so that the overall appearance of the machine to a higher level.

5, Equipped with special robot welding gun, welding quality is better and more stable.

III. Product overall using features

1, The machine is integrated design, easy to use, while reducing all kinds of messy external control lines, effectively prevent damage to the line and control, make the working environment more concise.

2, The lengthened magnetic seat on the track reduces the weight and number of switches with the same suction force, making it easy to install even for a woman.

3, The design of the special connecting plate for the track end is noteworthy. The bolt is used in the forward direction, which can connect two or more tracks into a longer whole. Bolt reverse use, can make the track fast, accurate lap, so that the length of infinite cycle.

4, Machine drive and control all adopt AC 20V voltage, more safe.

5, The professional welding gun used by this machine can be adapted to different welding gun joints, no matter you are using other welding machine, can be used perfectly.

6, The machine comes with toolbox is our company's original creation. The tool box is easy to use and durable. Some necessary small tools are stored in the tool box, which can reduce the time for users to search for tools and improve work efficiency. It is equipped with: fuse, welding gun conductive nozzle, all kinds of inner square Angle wrench, box ruler, notepad, pen, etc. When a perfect weld is adjusted, the weld parameters, the voltage and current of the welding machine and various parameters on the control panel of the machine are recorded. When the same weld is encountered next time, input parameters and perfect copy of the weld.

7, Flexible and convenient to use, non-welder can weld a perfect weld, one person can operate more than one machine at the same time, greatly reduce labor costs, improve the quality of weld, improve work efficiency.

MAJOR COMPONENTS

|

No.

|

Items

|

Configuration

|

Qty

|

Remarks

|

|

1

|

Machine body

|

Moving system

|

1 Set

|

Drive to travel

|

|

|

|

Oscillator

|

1 Set

|

Swing

|

|

|

|

Control system

|

1 Set

|

|

|

|

|

Travel switch

|

2 sets

|

Automatically stop welding at specified position

|

|

|

|

Flexible rail/tracks

|

2 pcs

|

1.5m *2 set

|

|

|

|

The magnet holder

|

8 stes

|

4Set/ pcs

|

|

2

|

Welding power

|

Transformers, fuses, etc

|

1 Set

|

AC220V to AC20V

|

|

3

|

Welding power source

|

MIG 500

|

1 Set

|

Including 5 meter control cable 1.5 ground cable, 3 meter welding cable and gun holder,and welding torch, wire feeder and gas meter

|

|

4

|

Welding cable and gun holder

|

5 meter

|

1 Set

|

Special welding gun for automatic welding

|

|

5

|

Spare parts

|

Fuse

|

5 pcs

|

1A

|

|

|

|

Conductive nozzle of welding torch

|

2 pcs

|

Φ1.0、Φ1.4with each one

|

|

6

|

Toolkit

|

Hexagon socket wrench

|

4 pcs

|

Size 3、4、5、6each one

|

|

|

|

Qualification certificate

|

1 pcs

|

|

|

|

|

Instruction

|

1 pcs

|

|

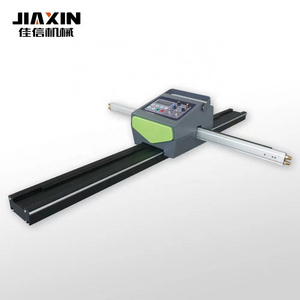

INSTALLATION PROCEDURE

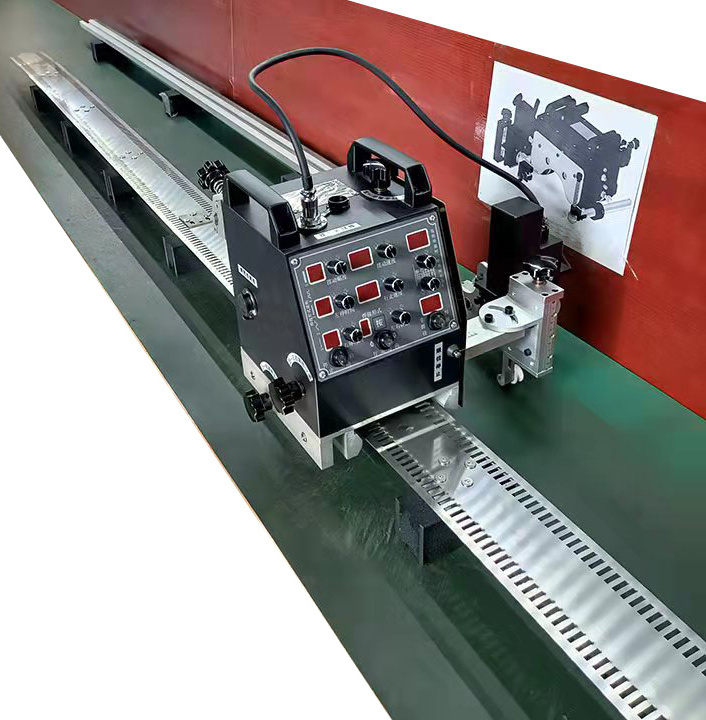

Straight rail installation:Step.1

* Use six M4*12 hex socket bolts to install three sets of magnet seats on the track. Note that the magnet handle is in the direction of the magnetic strip. The track is assembled. Another set of tracks can be connected to the end connecting plate for endless circulation use.

Step.2

* Install the welding robot from one end of the track to a track. Note that the walking clutch is in the open position. The clutch is in the closed position when used.

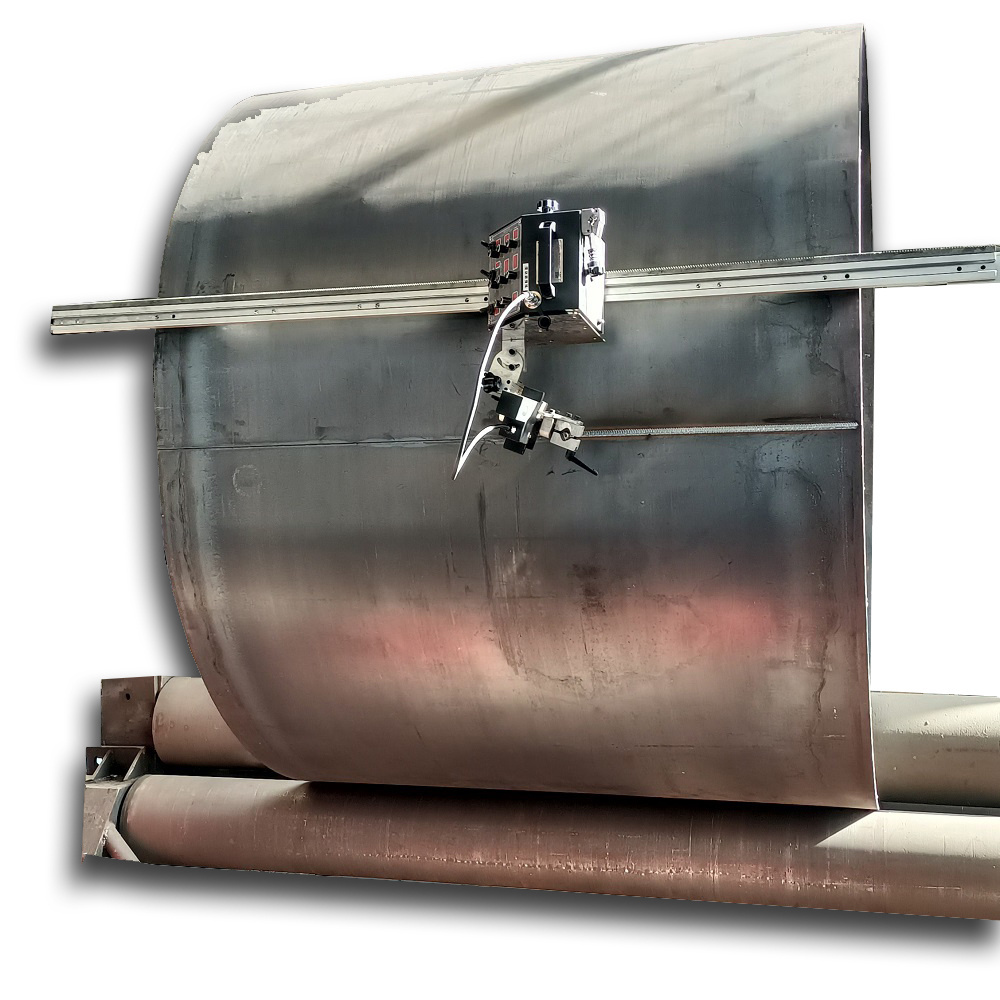

Flexible rail installation:Step.1

* Install the three sets of magnets on the three magnet positions in the middle of the track with 12 M6*16 flat head bolts and tighten them.

Step.2

* Release the track clutch, install the welding robot on the track, close the clutch, and the host can walk normally when in use.

Step.3

* Install the pressing plate, ultra-thin flat pad and soft rail on the magnet aluminum block with three M6*16 flat bolts in turn,tighten and assemble the track. Another set of track ends can be inserted under the platen for wireless circulation.

Step.4

* Adjust the external auxiliary to a reasonable height, and keep sliding support on the welding parts during welding, which can effectively prevent welding gun height or shake.

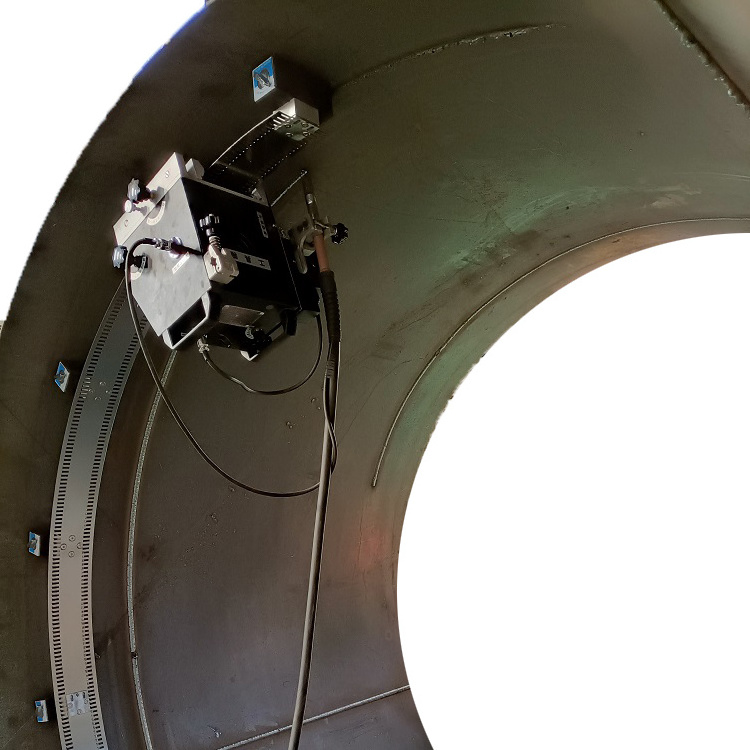

CONSTRUCTION SITE PHOTOS

COMPANY PROFILE

Wincoo Engineering Co., Ltd (WINCOO) is engaged in bringing the most suitable solutions/equipments for client, fabricators, EPC/C companies on pipe fabrication, tank construction, pipeline construction,industrial production lines, clean energy project and other industrial field.

Our Services & Strength

We have ability of providing workable solutions to support clients to be awarded with shorter project execution time, fewer man-hour cost and higher efficiency construction/fabrication method and better quality during phase of project bidding.

Based client’s facility/site space availability, we are able to study/design and present matched configurations on project

schedule, quality, cost and productivity to guarantee production pace is accordance with project requirement.

To support project execution, we are always ready to work as fireman to give prompt supply on project materials from different consumables, tools, equipments/machines to special merchandise. With flexibility, we are also glad to perform as procurement agent in China to seek required supply resources.

Hot Searches