- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

HK-QQJ

-

Brand Name:

-

HI-TEK

-

Standard or Nonstandard:

-

Standard

-

material:

-

316ss,304ss . duplex , A105

-

Temperature:

-

-57℃+250℃

-

Max Flange Rating:

-

2500LB class

-

features:

-

anti-corrison material

-

End connection:

-

RF,RTJ,FNPT

Quick Details

-

Port Size:

-

1/2" NPT

-

Warranty:

-

1 y

-

Place of Origin:

-

China

-

Model Number:

-

HK-QQJ

-

Brand Name:

-

HI-TEK

-

Standard or Nonstandard:

-

Standard

-

material:

-

316ss,304ss . duplex , A105

-

Temperature:

-

-57℃+250℃

-

Max Flange Rating:

-

2500LB class

-

features:

-

anti-corrison material

-

End connection:

-

RF,RTJ,FNPT

Product Information

|

Material

|

Stainless steel 316

|

|

Configuration

|

Ball-Needle-Ball or Ball-needle

|

|

Type

|

Split type

|

|

Flange Size

|

1/4"~2"

|

|

Pressure

|

from ASME Class 150 to ASME Class 2500.Max pressure 6000PSI

|

|

Temperature range

|

-70.6 F to 1022 F (-57℃ to +550℃)

|

|

Media

|

Oil,Gas

|

|

Features

|

Materials with anti-corrosion properties according to NACE MR 0175. Possibility of connection with valves or control instruments

|

|

Application

|

Instrumentation pipeline

|

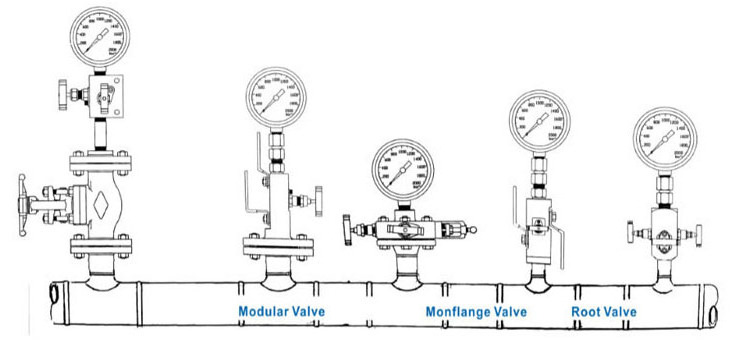

DBB Valve

Ball and globe style needle valve flange

Monoflange valve

Globe style needle valves flange and thread connection integrally forged body

Root valve

Ball and globe style needle valve

weld or thread connection direct connection to the vessel integrally

forged body

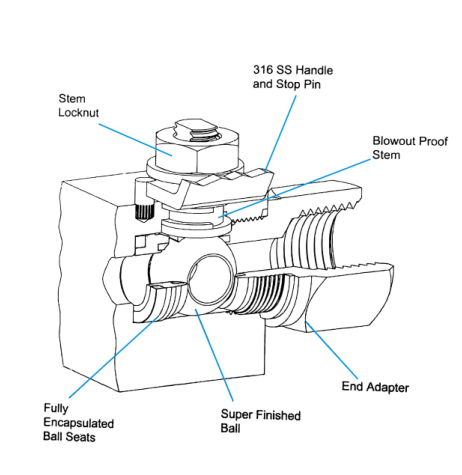

DBB BALL VALVE

Features

• Stainless steel handle and positive machined stop.

• Full grip PVC handle sleeve.

• Blowout proof one-piece stem spindle.

• Low operating torque.

• Fully encapsulated ball seats minimize seat seal extrusion and allow high working pressures.

• Super finished ball for low operating torque and long life.

• End adapter threads are fully isolated from process by primary and secondary static seals.

• Stem locknut is resistant to loose.

• Color coded and function identified handles.

• Firesafe to API 607.BS 6755 part 2.

• Bore size available 9.5mm to 20mm

• Ball seats choice of seat materials: PVDF, PTFE, PCTFE or PEEK.

DBB NEEDLE VALVE

Features

• Rolled stem threads prevent galling, stem threads are completely isolated from the process.

• Stem packing with Graphite or PTFE rings for bubble-tight seal.

• Stem tip construction : non-rotating self-centering,Anti-galling tip positive bubble-tight and field interchangeable tip.

• Backseat design provides secondary stem sealing and prevents stem blowout.

• Packing bolt allows easy access to adjust, the packing gland.

• Robust bar handle is standard.

• Color coded and function label for easy identification.

• Firesafe to API 607.BS 6755 part2.

• Orifice size 0.2"(5mm).

• Pressure rating up to 6,000psig (414barg).

• Temperature rating-70.6 F to +1022 F (-57 C to+ 550 C)

• Anti-Temper bonnet are available with a removable T-bar det to prevent unauthorized operation of vent valves.

DBB VALVE APPLICATION Block and Bleed valve Feature

•

Double block and bleed Instrument Isolation

•

Gauge Isolation .

• Instrument drain .

• Chemical Injection connection

• Sample connections

• Chemical seal Instrument Isolation

• Piping / Instrument Interface

• Direct mounting of instruments Remote

• mounting of Instruments

• Instrument drain .

• Chemical Injection connection

• Sample connections

• Chemical seal Instrument Isolation

• Piping / Instrument Interface

• Direct mounting of instruments Remote

• mounting of Instruments

• ANSI B16.5 flanged inlet connections 1/2" to 3" sizes Class 150 rated to class 2500 rated.

• 1/2"-1" F.NPT Thread outlet to ANSI/ASME B1.20.1 (depending on bore size).

• 1/2" F.NPT Th read vent connection to ANSI/ASME B1.20.1 • Standard materials of Stainless steel ASTM A182 F316/F316L, Carbon steel ASTM A350 LF2/A105, Duplex ASTM Al 82 F51.

• Optional materials include Super Duplex, Monel.

• Raised face and ring type joint flange styles.

• One-piece forged construction flange as standard

•

Fire safe designed (and tested) to meet BS 6755 Part 2/API 607.

• DBB & SBB Products meet the relevant code requirement of ASME Vlllz ASMEB 16.34, B16.5, B31.3 and API6D. Bubble tight shut off.

• locking and anti tamper devices for all valve types available option.

• Positive lever stop.

• User preferred handles.

• Permanent affixed reference label.

Test Report

Product Packaging

Related Products

Customers feedback

FAQ

Q: Are you trading company or manufacturer?

A: We are manufacturer and trading company . We have specialized in manufacturing fittings and valves for more than 12 years.

Q: Can you OEM?

Yes, we can OEM according to your drawings.

Q: How long is your delivery time?

A: In stock -- 1 to 7 days

No stock -- 7 to 30 days

Depending on the quantity

Q: Do you provide samples ? Is it free or extra?

A: Yes, we could offer the sample. You need to pay for it and the freight cost.

Q: What is your terms of payment ?

A: Payment<=3000USD, 100% in advance. Payment>=3000USD, 30% T/T in advance, balance before shipment.

If you have another question, pls feel free to contact us as below:

A: We are manufacturer and trading company . We have specialized in manufacturing fittings and valves for more than 12 years.

Q: Can you OEM?

Yes, we can OEM according to your drawings.

Q: How long is your delivery time?

A: In stock -- 1 to 7 days

No stock -- 7 to 30 days

Depending on the quantity

Q: Do you provide samples ? Is it free or extra?

A: Yes, we could offer the sample. You need to pay for it and the freight cost.

Q: What is your terms of payment ?

A: Payment<=3000USD, 100% in advance. Payment>=3000USD, 30% T/T in advance, balance before shipment.

If you have another question, pls feel free to contact us as below:

Hot Searches