- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YDF

-

Voltage:

-

220/24V~380/220V±5%

-

Power:

-

80Kw

-

Dimension(L*W*H):

-

22000*2950*4520mm

-

Weight:

-

70 kg

-

Name:

-

kraft Paper Making Machine

-

Keyword:

-

carton recycling machine

-

Finished Products:

-

jumbo kraft paper roll

-

Weight of paper:

-

40-180gsm

-

Raw material:

-

Rice straw or wheat straw

-

Experience:

-

since1980s

-

Width of paper:

-

1092mm

-

Operating speed(m/min):

-

40-80m/min

-

Dynamic balancing speed:

-

80m/min

-

Track Gauge:

-

2400

Quick Details

-

Production Capacity:

-

3Tons/Day

-

Product Type:

-

paper product making machinery

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

YDF

-

Voltage:

-

220/24V~380/220V±5%

-

Power:

-

80Kw

-

Dimension(L*W*H):

-

22000*2950*4520mm

-

Weight:

-

70 kg

-

Name:

-

kraft Paper Making Machine

-

Keyword:

-

carton recycling machine

-

Finished Products:

-

jumbo kraft paper roll

-

Weight of paper:

-

40-180gsm

-

Raw material:

-

Rice straw or wheat straw

-

Experience:

-

since1980s

-

Width of paper:

-

1092mm

-

Operating speed(m/min):

-

40-80m/min

-

Dynamic balancing speed:

-

80m/min

-

Track Gauge:

-

2400

Product Description

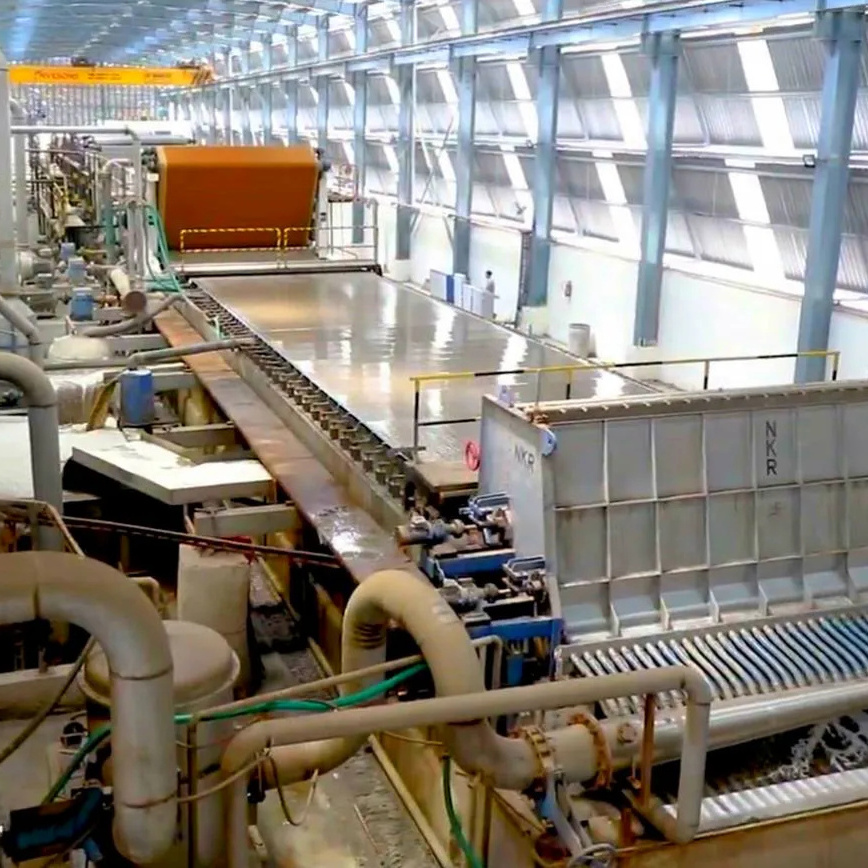

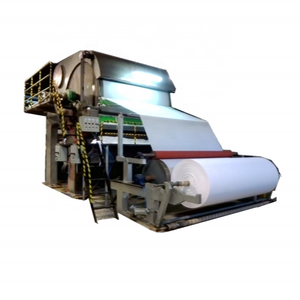

Wheat rice straw paper pulp mill machine is a device used to produce corrugated paper rolls from wheat straw and rice straw as raw materials. It is an environmentally friendly and sustainable solution to utilize agricultural waste products and reduce waste disposal. The machine involves a series of processes to convert the straw into pulp and then form it into corrugated paper rolls.

The wheat rice straw paper pulp mill machine typically consists of the following components:

1. Raw material preparation: The straw is collected, cleaned, and chopped to ensure uniformity in the pulp-making process.

2. Pulping: The chopped straw is subjected to a pulping process using water and chemicals to break down the straw fibers and create a pulp. The pulping process usually involves a refiner, pulper, and screen to separate the fibers from the liquid.

3. Fiber suspension: The pulped fibers are mixed with water to form a fiber suspension, which is then transported to the paper machine.

4. Paper formation: The fiber suspension is spread onto a wire screen, where the water is gradually removed, leaving the fibers to form a paper sheet. The sheet is passed through a series of rollers to ensure uniform thickness and moisture content.

5. Corrugation: The paper sheet is corrugated by passing it through a corrugating machine, which forms the distinctive wavy pattern on the paper. This process involves passing the paper through pairs of rollers with different diameters and curved surfaces.

6. Pressing and drying: The corrugated paper is pressed and dried to remove excess moisture and improve its strength and durability. This process typically involves passing the paper through heated rollers and dryers.

7. Finishing: The corrugated paper rolls are wound onto cores or finished with coatings and treatments to enhance their performance and appearance.

8. Output: The finished corrugated paper rolls are ready for use in various applications such as packaging, shipping, and construction.

By using wheat rice straw as raw material, the paper production process reduces reliance on non-renewable resources such as wood pulp, and also helps mitigate the environmental impact of agricultural waste disposal. Moreover, corrugated paper made from wheat rice straw has excellent strength, durability, and environmental friendliness, making it an ideal choice for various industries.

Specification

|

Marketing Type

|

New Product 2020

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

Engine, Motor, Bearing

|

|

Name

|

kraft Paper Making Machine

|

|

Keyword

|

rice straw or wheat straw pulp machine

|

|

Finished Products

|

jumbo kraft paper roll

|

|

Weight of paper

|

40-180gsm

|

|

Raw material

|

Rice straw or wheat straw

|

|

Experience

|

since1980s

|

|

Width of paper

|

1092mm

|

|

Operating speed(m/min)

|

40-80m/min

|

|

Dynamic balancing speed

|

80m/min

|

|

Track Gauge

|

2400

|

Packing & Delivery

1.Standard Exporting Packaging Form.

2.Wooden case /pallet, inner stretching film.

Hot Searches