Working parameters can be set easily without the need to train operators, which helps improve work efficiency. Operation panel

language can be customized in different languages, if you need, please contact us.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≥ 99.7%

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

ALWELL

-

Dimension(L*W*H):

-

3000*1500*2500mm

-

Weight:

-

500 KG, 500 KG

-

After-sales Service Provided:

-

Online Support

-

Product name:

-

Filling Line

-

Function:

-

Automatic Filling Capping Machine

-

Name:

-

Liquid Filling Machine

-

Usage:

-

Filling Capping Labeling Packaging

-

Bottle type:

-

PET Plastic Bottle Glass Bottle

-

Keywords:

-

Fillng Machine

Quick Details

-

Machinery Capacity:

-

4000BPH, 20000BPH, 16000BPH

-

Packaging Material:

-

Wood

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice, Powder

-

Filling Accuracy:

-

≥ 99.7%

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

ALWELL

-

Dimension(L*W*H):

-

3000*1500*2500mm

-

Weight:

-

500 KG, 500 KG

-

After-sales Service Provided:

-

Online Support

-

Product name:

-

Filling Line

-

Function:

-

Automatic Filling Capping Machine

-

Name:

-

Liquid Filling Machine

-

Usage:

-

Filling Capping Labeling Packaging

-

Bottle type:

-

PET Plastic Bottle Glass Bottle

-

Keywords:

-

Fillng Machine

Products Description

|

Brand

|

ALWELL

|

|

Type

|

Filling Machine

|

|

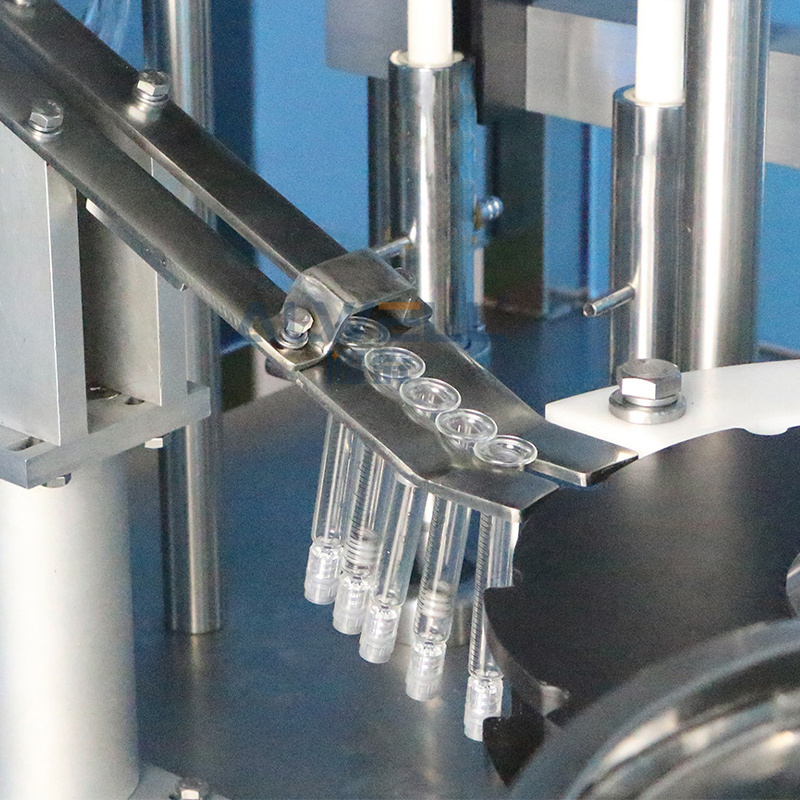

Number of filling heads

|

1/2

|

|

Filling range

|

1ml-10ml

|

|

Bottle diameter

|

5-100mm(Can Customize)

|

|

Bottle height

|

5-100mm

|

|

Working speed

|

10-15pes/min.(depending on liquid,bottle and caps)

|

|

Filling accuracy

|

1%

|

|

Qualified rate of finished products

|

Food/industry/medicine/Chemical

|

|

Applicable bottle

|

Can Customize

|

|

Warranty

|

1 Year

|

|

Material

|

Stainless Steel 304/316

|

|

Machine weight

|

About 750kg

|

|

Package size

|

About About 2500*1700*1750mm

|

Advantages and Details

1.

Intelligent control panel and touch screen control panel

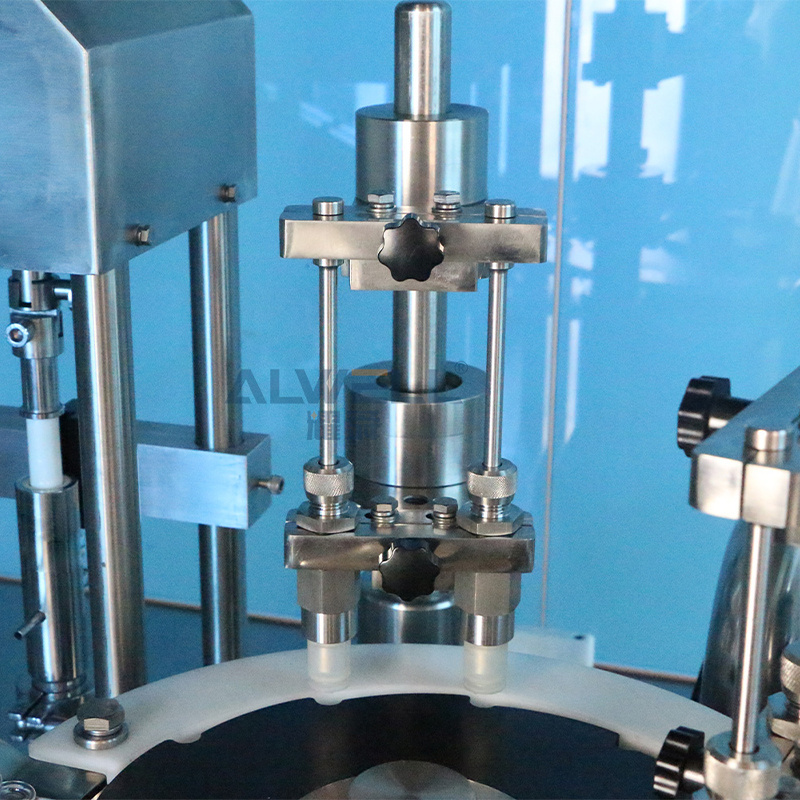

2.Stainless steel material

The surface is made of SUS304 stainless steel, and all the contact liquid parts are SUS316L stainless steel and medical silicone rubber, in line with the requirements of GMP

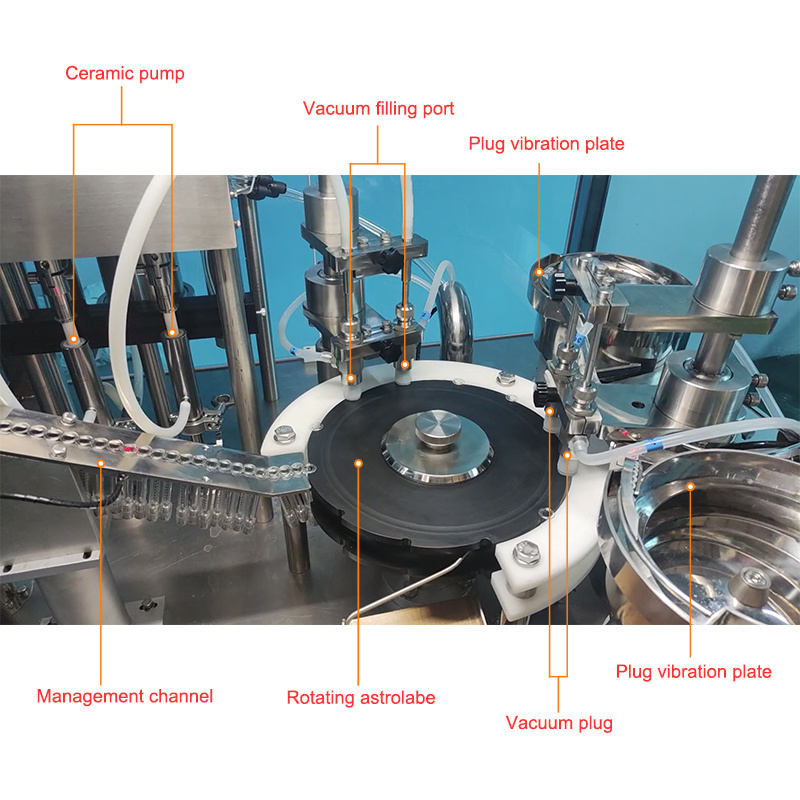

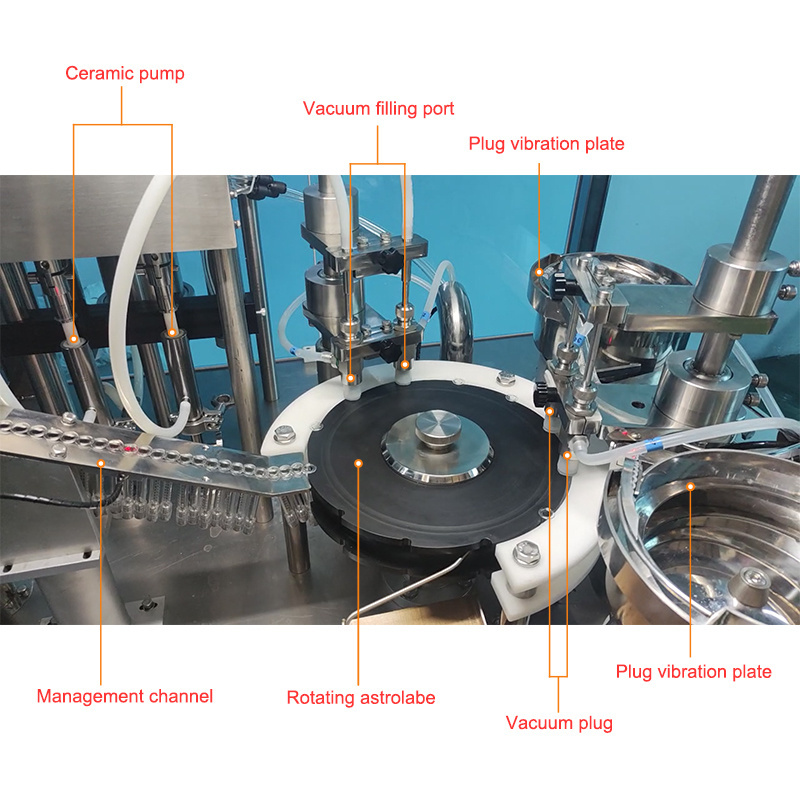

3.Vacuum filling system

Suitable for viscous materials, to ensure that the liquid filling space, and no bubble or fault to improve the qualified rate of finished products

4. Vacuum plug system

Vacuum plug filling system, avoid the rubber plug vibration friction caused by particles, ensure that the rubber plug and liquid level close contact

5.Rubber stopper vibration disc

The rubber stopper is arranged in an orderly manner, and the rubber stopper is combined with the vacuum stopper system to form a complete product

6. Rotating disk

Rotating the astrolabe helps the tube work steadily at different stations.

The rotating astrolabe should be customized according to the size of the tube, filling different tubes with different rotating astrolabes.

7.Detection electronic eye

Equipped with high quality electriceye,this can be used to detectbottles and make the machinestart or stop to work.The sensitivityof the electric can be adjusted bythe adjusting part. Improvesworking accuracy.

USE

This machine is mainly used for filling production line of test tubeand other small-dose products, which can realize automatic feeding,peristaltic pump filling, positioning cap, high-speed cap turning andautomatic labeling.

The machine adopts mechanical transmission to ensure accurate andstable operation, low noise, low loss, and no air pollution.The wholemachine is made of 304 stainless steel, in line with GMP requirements.

We'll change into your standard plug before shipping,such as American plug, UK plug, European plug...

* Complimentary installation kit

Product Application

Hot Searches