- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

20612070N

-

Safety Relief Valve:

-

Automatic

-

Body Material:

-

Brass

-

Surface Treatment:

-

Nickel

-

Connection:

-

BSP Thread

-

Working Pressure:

-

6 Bar to 10.5Bar

-

Valve Type:

-

with Free Handle

-

Certification:

-

Reach

Quick Details

-

Port Size:

-

1/2"-BSP

-

Warranty:

-

2 years

-

Place of Origin:

-

China

-

Model Number:

-

20612070N

-

Safety Relief Valve:

-

Automatic

-

Body Material:

-

Brass

-

Surface Treatment:

-

Nickel

-

Connection:

-

BSP Thread

-

Working Pressure:

-

6 Bar to 10.5Bar

-

Valve Type:

-

with Free Handle

-

Certification:

-

Reach

Product Description

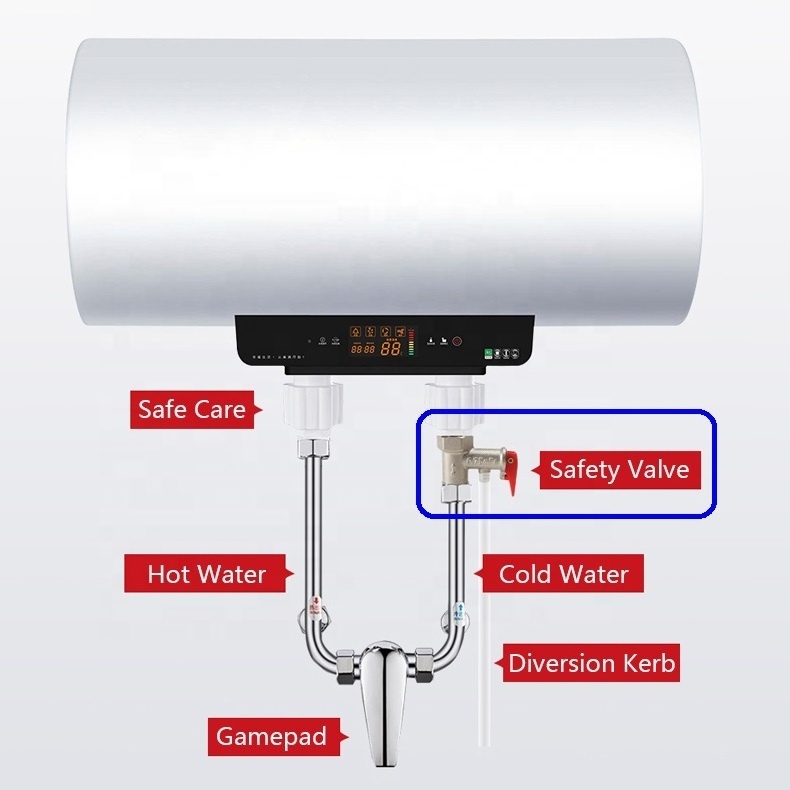

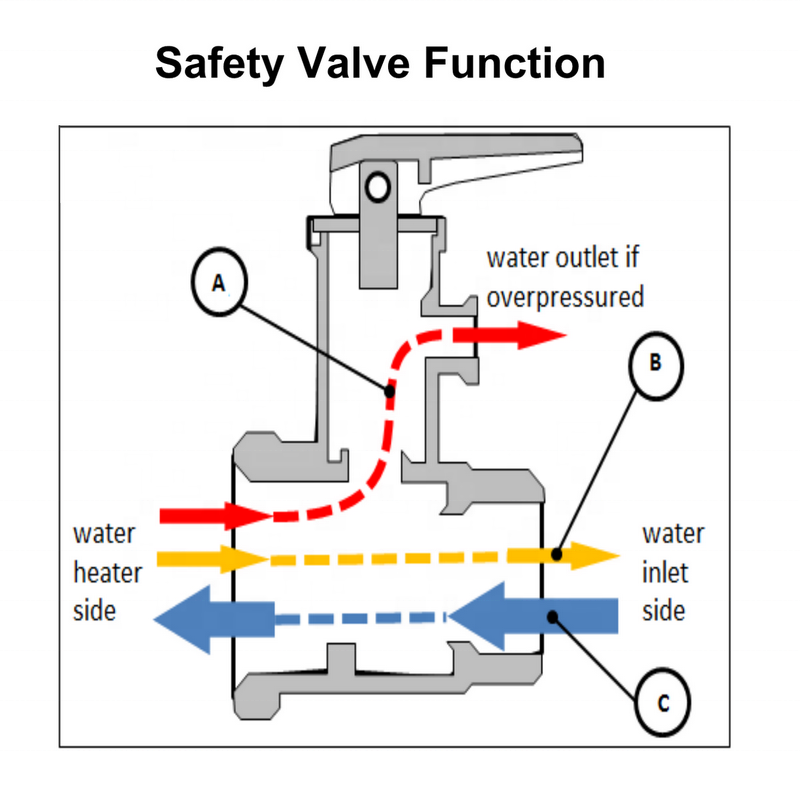

Weiling Safety Valve Function:

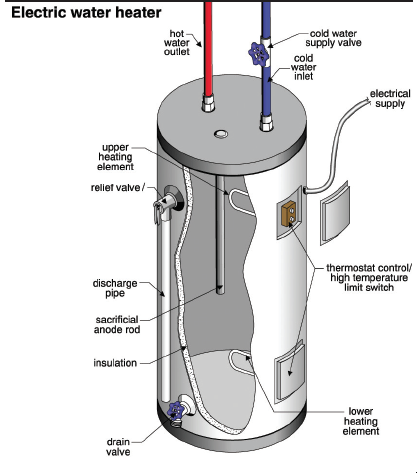

Safety component used on electric water heaters with capacities from 10 to 300 Liters to protect against over-pressure inside the water tank and prevent water from escaping (dry heating case).The safety valve is also dedicated to avoid explosion of the water tank (Human safety). The valve has to be watertight at the nominal water pressure, and particularly the area around the lever -- no droplet. The valve should be composed of 3 main functions A, B & C and a lever(lever could be optional in sometimes.):

1. Safety valve A: Normally closed, and when pressure increases in tank and overcomes the opening pressure: it opens and allows the exit of hot water/vapor from the security outlet (direction A). Then the pressure decreases and it moves back to closed state.

2. Non return B: Stops the water in the tank from exiting to inlet pipe network, this prevents emptying the tank and have a dry heating case that destroys the water heater and may cause excessive heating, and also fills the inlet network with hot water.

NOTE: The return valve C has to open and allow water to pass from water heater tank back to water inlet and

network (direction B), only if pressure on the water heater side is above 1.8 to max 4 bar(to be different depends on different water tank) the water pressure on the inlet side. Target of this requirement is to avoid continuous water drops through the safety valve A.

3. Entry C: When the user opens the hot tap, this valve should open to let enter cold water inside the tank equivalent of the exiting hot water (direction C). It should remain open as long as the hot tap is open, and return closed immediately when the tap is closed. It should respond to low values of the network pressure.

Safety component used on electric water heaters with capacities from 10 to 300 Liters to protect against over-pressure inside the water tank and prevent water from escaping (dry heating case).The safety valve is also dedicated to avoid explosion of the water tank (Human safety). The valve has to be watertight at the nominal water pressure, and particularly the area around the lever -- no droplet. The valve should be composed of 3 main functions A, B & C and a lever(lever could be optional in sometimes.):

1. Safety valve A: Normally closed, and when pressure increases in tank and overcomes the opening pressure: it opens and allows the exit of hot water/vapor from the security outlet (direction A). Then the pressure decreases and it moves back to closed state.

2. Non return B: Stops the water in the tank from exiting to inlet pipe network, this prevents emptying the tank and have a dry heating case that destroys the water heater and may cause excessive heating, and also fills the inlet network with hot water.

NOTE: The return valve C has to open and allow water to pass from water heater tank back to water inlet and

network (direction B), only if pressure on the water heater side is above 1.8 to max 4 bar(to be different depends on different water tank) the water pressure on the inlet side. Target of this requirement is to avoid continuous water drops through the safety valve A.

3. Entry C: When the user opens the hot tap, this valve should open to let enter cold water inside the tank equivalent of the exiting hot water (direction C). It should remain open as long as the hot tap is open, and return closed immediately when the tap is closed. It should respond to low values of the network pressure.

Specification:

|

Size

|

|

1/2" & 3/4"

|

|

|

|||

|

Material

|

|

Refined Brass (EN12165)

|

|

|

|||

|

Setting Relief Pressure

|

|

from 6-10 Bar or Can be Customized

|

|

|

|||

|

Surface

|

|

Brass, Nickel or Chrome Can be Optional

|

|

|

|||

|

Thread

|

|

BSP according to ISO 228-1(Other Thread can be customized)

|

|

|

|||

Packing & Delivery:

1. Each Piece is calibrated and tested before packing(100% test);

2. Every 10 pieces packed inside a strong neutral inner box, to have best protection;

3. Every 10 or 20 inner box inside a strong neutral carton, and labeled;

4. Each carton striped and palletized before transportation;

5. LCL or FCL shipment are both acceptable & workable for us;

3. Every 10 or 20 inner box inside a strong neutral carton, and labeled;

4. Each carton striped and palletized before transportation;

5. LCL or FCL shipment are both acceptable & workable for us;

6. Normally, delivery time will be varied from 35 days to 50 days when PI confirmed & payment done.

Hot Searches