- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Model Number:

-

TH-LHY031

-

Brand Name:

-

tianhao

-

Product name:

-

410 430 Magnetic stainless steel wire mesh

-

Keyword:

-

430 stainless steel wire mesh

-

Feature:

-

Corrosion Resistance

-

Sample:

-

Avaliable

-

MOQ:

-

1piece

-

Certification:

-

ISO

-

Advantage:

-

Rich Experience

-

Hole shape:

-

Square Hole

-

Packing:

-

Wooden Box

-

special specification:

-

custom

Quick Details

-

Material:

-

STAINLESS STEEL WIRE

-

Type:

-

Wire Cloth

-

Application:

-

Filters

-

Place of Origin:

-

Hebei, China

-

Model Number:

-

TH-LHY031

-

Brand Name:

-

tianhao

-

Product name:

-

410 430 Magnetic stainless steel wire mesh

-

Keyword:

-

430 stainless steel wire mesh

-

Feature:

-

Corrosion Resistance

-

Sample:

-

Avaliable

-

MOQ:

-

1piece

-

Certification:

-

ISO

-

Advantage:

-

Rich Experience

-

Hole shape:

-

Square Hole

-

Packing:

-

Wooden Box

-

special specification:

-

custom

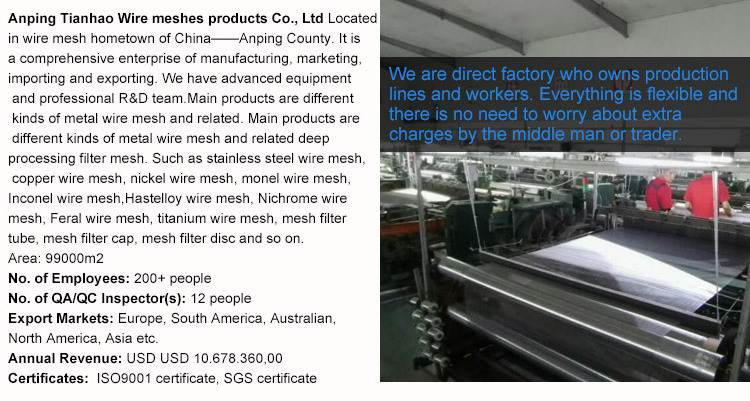

Product Description

|

Product Name

|

Woven Wire Mesh, Wire Cloth

|

|

Stainless Steel Grade

|

304, 304L, 316, 316L, 310s, 904L, 430, etc

|

|

Special Material Options

|

Inconel, Monel, Nickel, Titanium, etc

|

|

Wire Diameter

|

0.02 - 6.30mm

|

|

Hole Size Range

|

1 - 3500mesh

|

|

Weave Types

|

Plain Weave,Twill Weave,Dutch Weave,Plain Dutch Weave

Twill Dutch Weave,Reverse Dutch Weave,Multiplex Weave. |

|

Mesh Width

|

Standard less than 2000 mm

|

|

Mesh Length

|

30m rolls or cut to length, minimum 1m

|

|

Mesh Type

|

Rolls and sheets are available

|

|

Production Standards

|

ASTM E2016 - 20

|

|

Certification

|

ISO9001: 2015

|

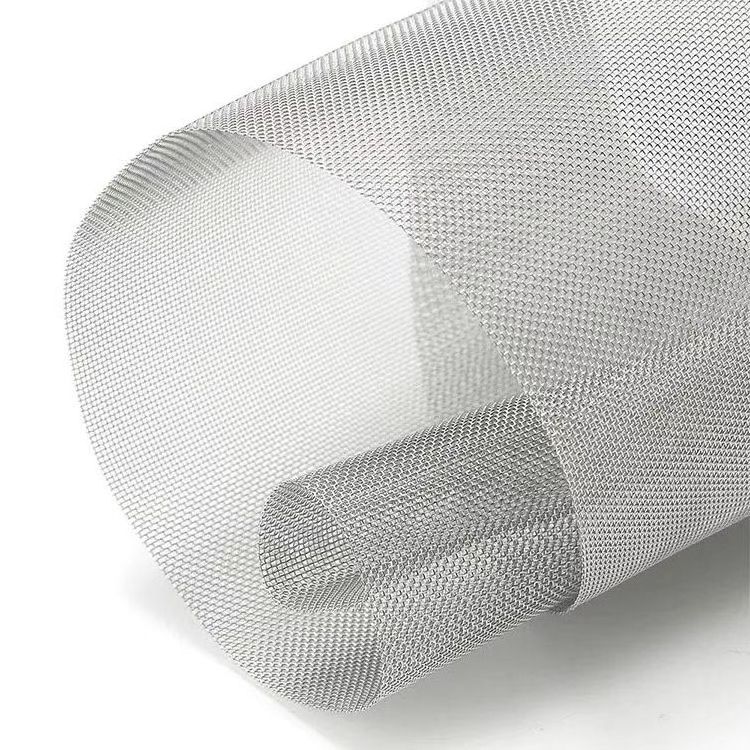

Woven wire mesh or woven wire cloth, is woven by machine. It is similar to the process

of weaving clothing, but it is made of wire. The mesh can be woven in different weave

styles. Its purpose is to produce solid and reliable products to adapt to various complex

application environments.High precision technology makes the production cost of woven

wire mesh higher, but it also has a very wide range of uses.

of weaving clothing, but it is made of wire. The mesh can be woven in different weave

styles. Its purpose is to produce solid and reliable products to adapt to various complex

application environments.High precision technology makes the production cost of woven

wire mesh higher, but it also has a very wide range of uses.

The main materials are 304 stainless steel wire mesh, 316 stainless steel wire mesh, 310

stainless steel wire mesh, 904L stainless steel wire mesh, 430 stainless steel wire mesh,

and other stainless steel grade. The most popular ones are 304 stainless steel wire mesh

and 316 stainless steel wire mesh, which can be used in most application environments

and are not expensive.

And some special materials are used to meet the high requirements of the use environment, such as Inconel wire mesh, Monel Wire Mesh, Titanium Wire Mesh, Pure Nickel Mesh, and Pure Silver Mesh, etc.

stainless steel wire mesh, 904L stainless steel wire mesh, 430 stainless steel wire mesh,

and other stainless steel grade. The most popular ones are 304 stainless steel wire mesh

and 316 stainless steel wire mesh, which can be used in most application environments

and are not expensive.

And some special materials are used to meet the high requirements of the use environment, such as Inconel wire mesh, Monel Wire Mesh, Titanium Wire Mesh, Pure Nickel Mesh, and Pure Silver Mesh, etc.

Weave Types

Tianhao Wire Mesh can provide many different weaves to meet different application needs.the weave styles mainly depend on the mesh and wire diameter specifications of the woven mesh. Below are the show of some common styles we weave here.

Product Application

Perfectly suited for a wide array of architectural and functional purposes, stainless steel wire mesh is used in various industries. The petroleum, chemical environmental protection,

mining, aerospace, paper making, electronic, metallurgical, food and pharmaceutical

industries all utilize woven wire mesh.

mining, aerospace, paper making, electronic, metallurgical, food and pharmaceutical

industries all utilize woven wire mesh.

The above are some of the applications of wire mesh we listed. In fact, woven wire mesh

has a seemingly infinite range of applications. Because it has many irreplaceable features

and advantages, there can be few industries where wire mesh does not have a part to play.

Wire mesh offers many benefits including:

-Widest range filtration, from over 6-inch aperture down to 1-micron nominal.

-High open area/flow rate.

-Closely controlled, accurate apertures.

-Smooth surface - screening surface has no sharp edges, burrs or acute angles.

-Very high-temperature tolerance (variable according to metal selected).

-Usable under high pressure.

-Flexible - ideal for forming rigid concave / convex shapes.

-Control of chemical/acid/ corrosion resistance using different metals.

-Special aperture requirements can be met without high tooling costs.

-High durability.

-Self-supporting.

-Suitable as upper for less rigid media.

-Stable under tension

-The weaving process uses no punching, piercing or stretching operations that create

stress-induced weaknesses.

-Point contact only on the screened product allows freer screening and reduced binding.

-Corrosion, abrasion and heat resistance.

-Highly aesthetic appeal for architectural applications.

-Hygienic characteristics and clean ability are specifically suitable for the food and

pharmaceutical industries.

-Cost-effective.

has a seemingly infinite range of applications. Because it has many irreplaceable features

and advantages, there can be few industries where wire mesh does not have a part to play.

Wire mesh offers many benefits including:

-Widest range filtration, from over 6-inch aperture down to 1-micron nominal.

-High open area/flow rate.

-Closely controlled, accurate apertures.

-Smooth surface - screening surface has no sharp edges, burrs or acute angles.

-Very high-temperature tolerance (variable according to metal selected).

-Usable under high pressure.

-Flexible - ideal for forming rigid concave / convex shapes.

-Control of chemical/acid/ corrosion resistance using different metals.

-Special aperture requirements can be met without high tooling costs.

-High durability.

-Self-supporting.

-Suitable as upper for less rigid media.

-Stable under tension

-The weaving process uses no punching, piercing or stretching operations that create

stress-induced weaknesses.

-Point contact only on the screened product allows freer screening and reduced binding.

-Corrosion, abrasion and heat resistance.

-Highly aesthetic appeal for architectural applications.

-Hygienic characteristics and clean ability are specifically suitable for the food and

pharmaceutical industries.

-Cost-effective.

Hot Searches