- Product Details

- {{item.text}}

Quick Details

-

Production Speed(Cycles/min):

-

60

-

Air Pressure(MPa):

-

0.4 MPa

-

Heating Power (kW):

-

1.2 kW

-

Air Comsumption(L/min):

-

1 L/min

-

Water Comsumption(L/min):

-

1 L/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

QC

-

Voltage:

-

380v / 220v / 50HZ

-

Dimension(L*W*H):

-

2500*880*1600mm

-

Weight (T):

-

1000 T

-

Weight:

-

1000kg

-

Power:

-

380v / 220v / 50HZ

-

Capacity:

-

3600 PC/h- 6000 PC/h

-

Package size:

-

2500*880*1600mm

Quick Details

-

Max.Forming Height(mm):

-

150 mm

-

Forming Width (mm):

-

150 mm

-

Forming Length (mm):

-

350 mm

-

Production Speed(Cycles/min):

-

60

-

Air Pressure(MPa):

-

0.4 MPa

-

Heating Power (kW):

-

1.2 kW

-

Air Comsumption(L/min):

-

1 L/min

-

Water Comsumption(L/min):

-

1 L/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

QC

-

Voltage:

-

380v / 220v / 50HZ

-

Dimension(L*W*H):

-

2500*880*1600mm

-

Weight (T):

-

1000 T

-

Weight:

-

1000kg

-

Power:

-

380v / 220v / 50HZ

-

Capacity:

-

3600 PC/h- 6000 PC/h

-

Package size:

-

2500*880*1600mm

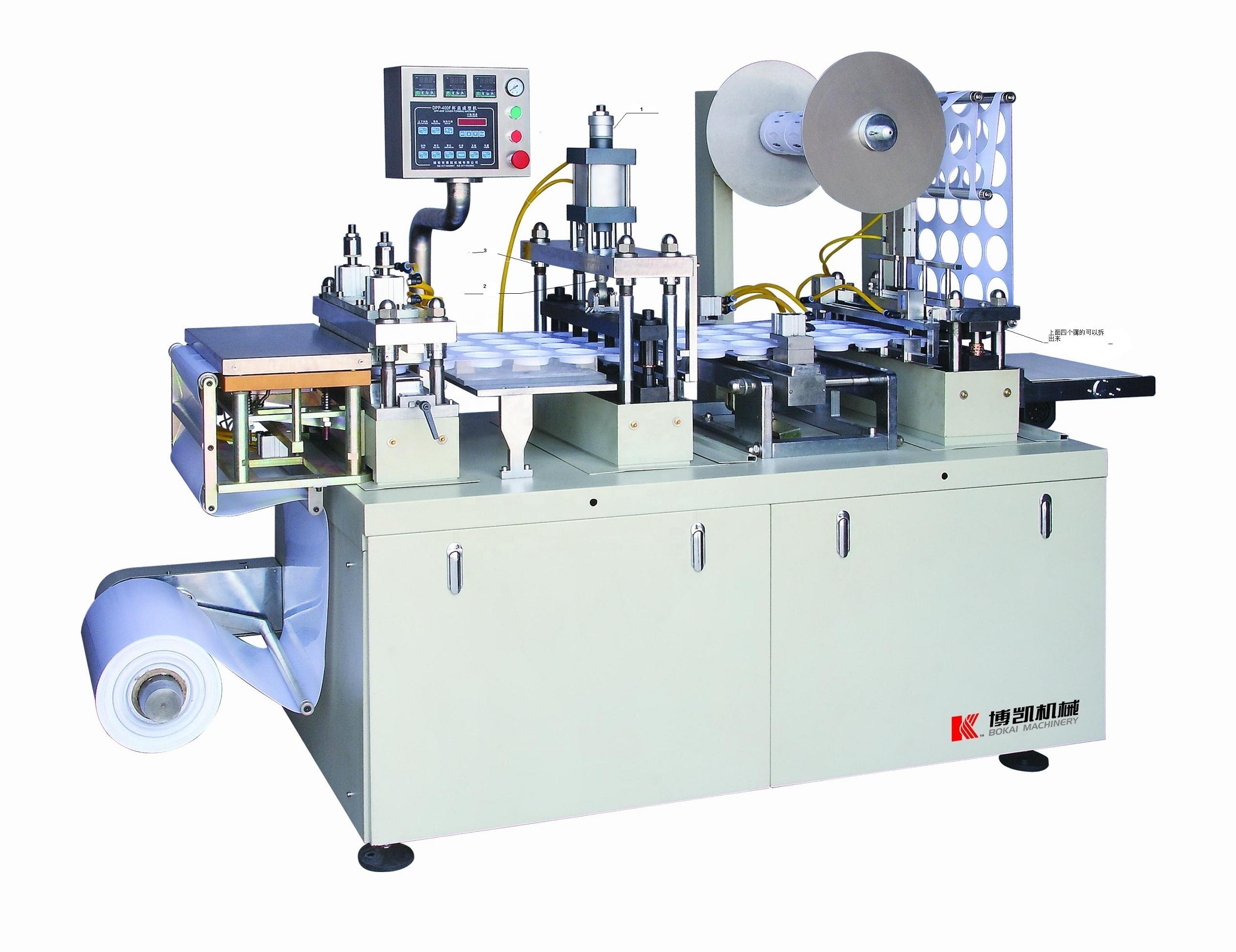

Welcome to visit our QC-350 cup lid machine .

We will provide you with the most considerate service. It is helpful that you find the most appropriate products you need . Your demand is our direction !!!

Features :

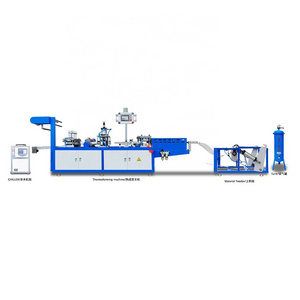

The machine integrates of electricity and optics the technology like: PC auto-controlling, transducer regulating, the piece of material heated up by temperature, molding by air-press to cutting the finished product, and the numbers of the products can input to the machine. The flow is in a high automatic fuction. It is configure the PLC computer control.

Main technical parameters:

|

Model |

QC-350 automatic plastic cup lid making machine |

|

Cutting Frequency |

15—45 (times/ min) |

|

Power |

380v / 220v / 50HZ |

|

Stroke adjustable range |

30—150mm |

|

Max. Forming Depth |

30mm |

|

Max. Forming Area |

350*150mm |

|

Capacity |

3600 PC/h- 6000 PC/h |

|

Motor Power |

1.5 kw |

|

Pressure |

0.4—0.7mpa |

|

Package size |

2500*880*1600mm |

|

Weight |

1000kg |

|

Need to buy an air compressor |

|

Characteristics: :

1 , Compact structure, smooth moving , convenient operation and easy maintenance.

2 , Infinitely variable frequency speed regulation, PLC circuit control panel.

3 , Adjustable route, mould changing more easily.

4 , It adopts manipulation grip to feeding, accurate and reliable synchronously.

5 , Designing all mould according to customers ’ requirements.

Application:

This plastic forming machine is used for thermoforming all kinds plastic material such as BOPS / HIPS / PS / PVC / PET and so on , which is widely used for making all kinds of caps & tray. such as :mini type soup spoon, cover of the dish ,salver of me.