- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

MBS

-

Power:

-

72 KW

-

Weight:

-

10000 kg

-

Marketing Type:

-

Hot Product 2024

-

Product name:

-

Automatic Insulationg Glass Making Machine

-

Selling Point:

-

Fully Automatic

-

Size 1 : length*width*height (m):

-

26 * 2.5 * 3.4

-

Size 2 : length*width*height (m):

-

32 * 2.5 * 3.7

-

Thickness of Insulating Glass:

-

12 - 50 mm

-

Making Glass Shape:

-

Square or rectangle

-

Application Range:

-

Windows, curtain wall,doors, refrigerator

-

Terms:

-

EXW, FOB, CFR, CIF, etc.

-

After-sales Service Provided:

-

Onsite training + Online support

-

Production Time:

-

50 - 60 Days

Quick Details

-

Machine Type:

-

Insulating Glass Production Line

-

Glass Thickness:

-

12-50mm

-

Production Capacity:

-

100%

-

Place of Origin:

-

China

-

Brand Name:

-

MBS

-

Power:

-

72 KW

-

Weight:

-

10000 kg

-

Marketing Type:

-

Hot Product 2024

-

Product name:

-

Automatic Insulationg Glass Making Machine

-

Selling Point:

-

Fully Automatic

-

Size 1 : length*width*height (m):

-

26 * 2.5 * 3.4

-

Size 2 : length*width*height (m):

-

32 * 2.5 * 3.7

-

Thickness of Insulating Glass:

-

12 - 50 mm

-

Making Glass Shape:

-

Square or rectangle

-

Application Range:

-

Windows, curtain wall,doors, refrigerator

-

Terms:

-

EXW, FOB, CFR, CIF, etc.

-

After-sales Service Provided:

-

Onsite training + Online support

-

Production Time:

-

50 - 60 Days

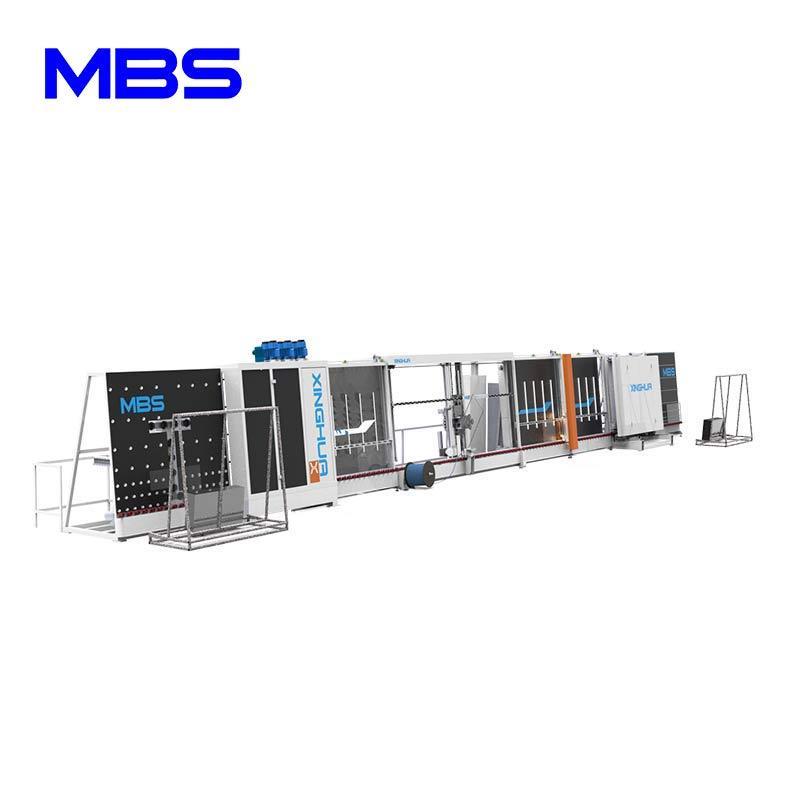

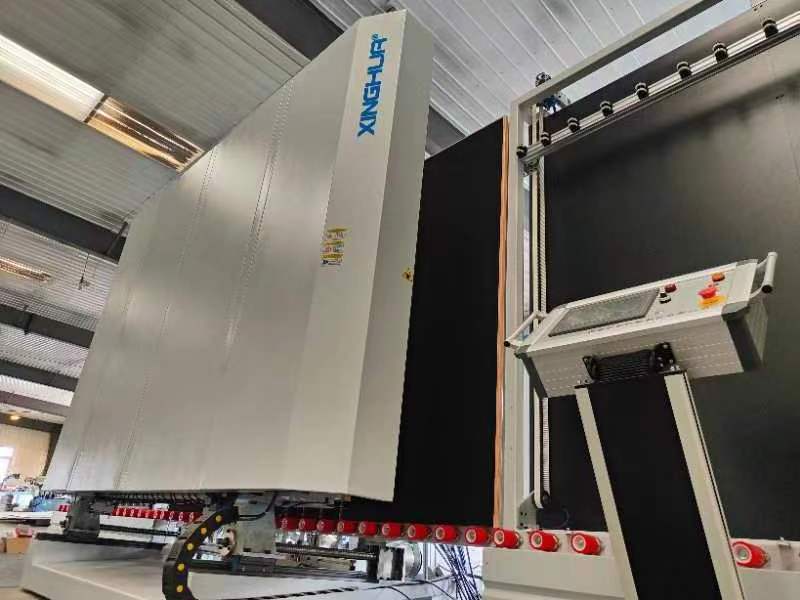

Vertical Warm Edge Insulating Glass Production Line

Product Overview

Features of our MBS vertical insulating glass production line:

1. This production line is an independent intellectual property rights that we independently developed.

2. All procedures, from washing to sealant, they are fully automatic. Completely controlled by the PLC system, simple operation, and humanization.

3. Two purposes on one machine, which can automatically produce flexible warm-edge hollow glass, on the other hand, it can meet the production of traditional groove aluminum hollow glass.

4. The patented Spacer Applicator, which uses a servo multi-axis linkage, and the glass rotation method quickly and accurately realizes the automatic upper entry. Improve product accuracy while improving production efficiency. To achieve the purpose of less labor and higher production capacity.

5. Consistent loading to ensure that the three or multilayered glass are in same position, same speed.

6. Washing inverter controls the brush to rotate, so that it can protect LOW-E glass.

7. Intelligent automatic spacer heating equipment, it only heat the spacer separately, automatically heat and the light is on when the glass come in to achieve efficient energy saving.

8. The multi-cavity insulating glass can be automatically pressed and inflated according to the set number of glass layers.

9. The semi-finished glass section can be automatically sealed online in the last procedure. By using our MBS (Multi-layered Butyl Spacer), finished glass does not need twice sealant.

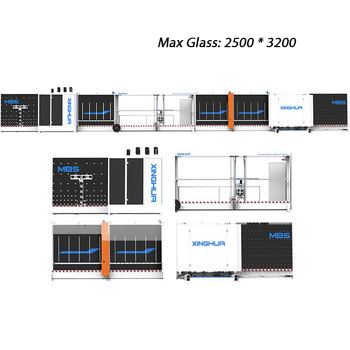

Product Paramenters

|

Specification

|

V2025

|

V2532

|

|

|

Size: length*width*height (m)

|

26 * 2.5 * 3.4

|

32 * 2.5 * 3.7

|

|

|

Max Glass (mm)

|

2000 * 25000

|

2500 * 3200

|

|

|

Min Glass (mm)

|

400 * 450

|

350 * 450

|

|

|

Speed of Spacer Applicator

|

50 sec for one layer of 1*1m insulating glass

|

50 sec for one layer of 1*1m insulating glass

|

|

|

Thickness of Insulating Glass

|

12 – 50 mm

|

12 – 50 mm

|

|

|

Thickness of Washing Glass

|

4 - 8mm

|

4 - 8mm

|

|

|

Thickness of Pressing Glass

|

≤ 8mm

|

≤ 8mm

|

|

|

Multi-layered Glass Requirements

|

Side ≤ 100mm, Bottom ≤ 50mm

|

Side ≤ 100mm, Bottom ≤ 50mm

|

|

|

Conveying Speed

|

0 - 45m/min

|

0 - 45m/min

|

|

|

Power

|

72 KW

|

72 KW

|

|

|

Voltage

|

3P 380V/1P+N 220V 50Hz

|

3P 380V/1P+N 220V 50Hz

|

|

|

Air Pressure

|

0.6 ± 0.05MPa

|

0.6 ± 0.05MPa

|

|

|

Air Consumption

|

1.5 m3 / Min

|

1.5 m3 / Min

|

|

|

Water Tank Volume

|

200 L (water ≤ 40℃)

|

200 L (water ≤ 40℃)

|

|

|

Water Conductivity

|

≤3 0ps/cm

|

≤3 0ps/cm

|

|

|

Air Quantity

|

4s±1s ( 1m×1m×12A IG,argon>90%)

|

4s±1s ( 1m×1m×12A IG,argon>90%)

|

|

|

Production Time

|

50 Days

|

50 Days

|

|

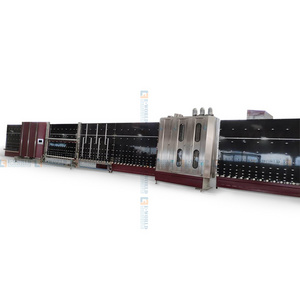

Product Configuration

1 Automatic Loading Machine

2 Automatic Washing&Dring Machine

3 Conveying

.

4 P

atented Spacer Applicator

5 Heating

6 Argon Inflation

7 Pressing

8 Automatic Sealling

9 Glass Sample Done

Tips: Each part of equipment can be sold respectively,

we aim to offer the most excellent service and best price to you!

Product Packaging

Glass Samples

Our machines can make virious glass..

Contact us for more

evaluation...

FAQ

Q1: Are you a manufacturer?

Yes, we have our own worshop in Panjin city. We are the professional insulating glass processing machines manufacturer with 20 years experience.

Q2: What do you supply?

We are specialized in manufacturing glass spacers for different glass, and glass machines like vertical and horizontal warm-edge insulating glass production lines, fireproof glass production lines, and inlaid glass production lines, etc. Furthermore, we are also selling full range of related accessories for glass production line.

Q3: How about the service ?

1). Reply it at once in WhatsAPP,if by email,it will be reply within 12 hours.

2). Our professional technicians will install and adjust the line at your plant and help train the workers.

3). 24-7 online technical support after sale. Point-to-point service help you solve the problems timely.

Q4: What's the guarantee ?

1). Our guarantee for 12 months.

2). Life time parts repair and replacement

Yes, we have our own worshop in Panjin city. We are the professional insulating glass processing machines manufacturer with 20 years experience.

Q2: What do you supply?

Q3: How about the service ?

1). Reply it at once in WhatsAPP,if by email,it will be reply within 12 hours.

2). Our professional technicians will install and adjust the line at your plant and help train the workers.

3). 24-7 online technical support after sale. Point-to-point service help you solve the problems timely.

Q4: What's the guarantee ?

1). Our guarantee for 12 months.

2). Life time parts repair and replacement

Exhibition

Hot Searches