- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

CNC machining parts

-

Brand Name:

-

7 Swords

-

Keyword:

-

Acetal Machining

-

Product name:

-

Milling ABS Brass CNC Plastic Acetal Machining

-

Service:

-

CNC Machining Service

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Material:

-

POM,acetal,plastic

-

Certification:

-

TUV,ISO

-

MOQ:

-

100-500pcs

-

OEM/ODM:

-

Accecpted

-

Color:

-

Clear,black

-

Tolerance:

-

0.01- +/-0.005mm

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Stainless steel, Steel Alloys, Plastic

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

CNC machining parts

-

Brand Name:

-

7 Swords

-

Keyword:

-

Acetal Machining

-

Product name:

-

Milling ABS Brass CNC Plastic Acetal Machining

-

Service:

-

CNC Machining Service

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Material:

-

POM,acetal,plastic

-

Certification:

-

TUV,ISO

-

MOQ:

-

100-500pcs

-

OEM/ODM:

-

Accecpted

-

Color:

-

Clear,black

-

Tolerance:

-

0.01- +/-0.005mm

|

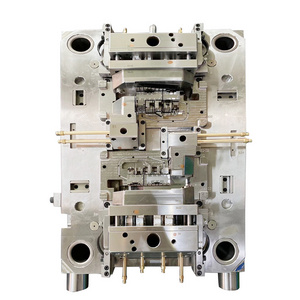

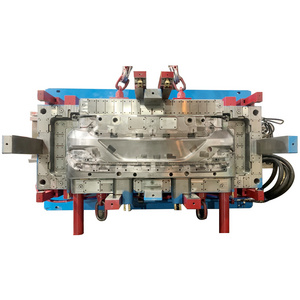

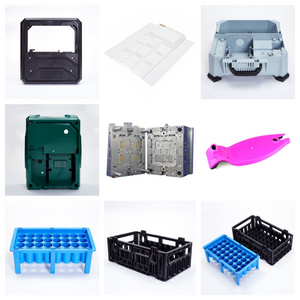

High Quality Plastic Parts (CNC Machining/ Injection Molding)

|

|

|

|

|

||||

|

Service

|

CNC Machining, Injection Molding

|

|

|

|

||||

|

Mould Base

|

LKM Stand Moldbase + Copy HASCO Components

|

|

|

|

||||

|

Cavity&Core

|

P20/ H13/ NAK80/ S50C/ S136/ 2344/ 738H, etc.

|

|

|

|

||||

|

Plastic Materials

|

PP, PC, PA, PA6, ABS+PC, PET, POM, PEEK, ABS, Nylon, PVC, Acrylic, etc.

|

|

|

|

||||

|

Surface Treatment

|

Polish, Texture, Frosted, Heat Treatment, etc.

|

|

|

|

||||

|

Gate System

|

Cold Runner/ Hot Runner

|

|

|

|

||||

|

Cavities

|

Single/ Multiple/ Family Mold

|

|

|

|

||||

|

Lead Time

|

3~6 weeks usually (after DFM report confirmed)

|

|

|

|

||||

|

Mould Life

|

Prototype ~ 1,000,000 shots

|

|

|

|

||||

|

Quality Assurance

|

ISO9001:2015, ISO13485:2016, SGS, ROHS, TUV

|

|

|

|

||||

|

Drawing Accepted

|

Solid Works, Pro/ Engineer, Auto CAD(DXF, DWG), PDF

|

|

|

|

||||

|

Mould Package

|

Wood Box with Pallet

|

|

|

|

||||

|

Payment Terms

|

Trade Assurance, TT, Paypal, WestUnion

|

|

|

|

||||

|

|

|

|

|

|||||

CERTIFICATIONS

We are proud to hold several production certificates for our CNC machining services,which demonstrates our commitment to qual

ity

and customer satisfaction.

1、ISO13485:MEDICAL DEVICES QUALITYMANAGEMENT SYSTEM CERTIFICATE

2、ISO9001:QUALITY MANAGEMENT SYSTEMCERTIFICATE

3、IATF16949、AS9100D、SGS、CE、CQC、RoHS

FACTORY SHOW

CUSTOMER PHOTOS

CUSTOMER REVIEW

Welcome to a world where precision meets excellence, where our machining services have left a trail of satisfied customers who couldn't help but sing our praises. We are proud to showcase the resounding positive feedback that speaks volumes about the exceptional quality, reliability, and craftsmanship that define our work.This is just a part of buyer feedback, we have more positive feedback, you are welcome to learn more about us.

Aerospace:

The aerospace industry requires precision parts with high accuracy and tight tolerances. CNC machining services areused to produce parts such as turbine blades, engine components, and structural parts.

Automotive:

The automotive industry relies on CNC machining services to produce high-precision parts for engines, transmissions, and other critical components.

Motorcycles:

Engine components,Suspension components,Wheels,Brakes,Frame and chassis components,Exhaust systems.

Bicycle:

Bike frames,Forks,Handlebars,Pedals,Brake components,Cranksets,Hubs.

Medical:

The medical industry requires precision parts for various medical devices and equipment. CNC machining services are used to produce components for surgical instruments, implants, and prosthetics.

Electronics:

The electronics industry requires precise components for various electronic devices. CNC machining

services are used to produce components for circuit boards, connectors, and other electronic devices.

services are used to produce components for circuit boards, connectors, and other electronic devices.

Oil and gas:

The oil and gas industry relies on CNC machining services to produce components for drilling equipment, pumps, valves, and other critical components.

Robotics:

The robotics industry requires precision components for robots and automation systems. CNC machining

services are used to produce components such as gears, actuators, and other robotic parts.

services are used to produce components such as gears, actuators, and other robotic parts.

Industrial machinery:

CNC machining is used to produce parts for a wide range of industrial machinery, including pumps, valves, and bearings.

Construction:

The construction industry uses CNC machined parts for components such as structural steel, cladding systems, and architectural features.

Agriculture:

The agriculture industry uses CNC machined parts for components such as irrigation systems, seed drills,

and harvesting equipment.

and harvesting equipment.

Marine:

The marine industry uses CNC machined parts for components such as propellers, rudders, and hull structures.

Packaging:

The packaging industry uses CNC machined parts for components such as molds, dies, and cutting tools.

Food processing:

The food processing industry uses CNC machined parts for components such as cutting tools, conveyor systems, and mixing equipment.

Furniture:

The furniture industry uses CNC machined parts for components such as chair frames, table legs, and decorative features.

FAQ

A: Are you a manufacturer or a trading company?

Q: We are a 3000-square-meter factory located in Shenzhen, China.

A: How can I get a quote?

A: How can I get a quote?

Q: Detailed drawings (PDF/ STEP/ IGS/ DWG...) with material, quantity and surface treatment information.

A: Can I get a quote without drawings?

A: Can I get a quote without drawings?

Q: Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

A: Will my drawings be divulged if you benefit?

Q: No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need.

A: Can you provide samples before mass production?

Q: Sure, sample fee is needed, will be returned when mass production if possible.

A: How about the lead time?

Q: 3~6 weeks usually ( after DFM report confirmed )

A: How do you control the quality?

Q: (1) Material inspection--Check the material surface and roughly dimension.

(2) Production first inspection--To ensure the critical dimension in mass production.

(3) Sampling inspection--Check the quality before sending to the warehouse.

(4) Pre-shipment inspection--100% inspected by QC assistants before shipment.

A: What will you do if we receive poor quality parts?

Q: Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.

A: Will my drawings be divulged if you benefit?

Q: No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need.

A: Can you provide samples before mass production?

Q: Sure, sample fee is needed, will be returned when mass production if possible.

A: How about the lead time?

Q: 3~6 weeks usually ( after DFM report confirmed )

A: How do you control the quality?

Q: (1) Material inspection--Check the material surface and roughly dimension.

(2) Production first inspection--To ensure the critical dimension in mass production.

(3) Sampling inspection--Check the quality before sending to the warehouse.

(4) Pre-shipment inspection--100% inspected by QC assistants before shipment.

A: What will you do if we receive poor quality parts?

Q: Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.

Hot Searches