- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V, 380V/50Hz/400V/60Hz

-

Power:

-

0

-

Dimension(L*W*H):

-

2400x1100x800(mm)

-

Weight (KG):

-

10000

-

Application:

-

steel

-

Function:

-

Molding

-

Type:

-

Fully Automatic

-

Product name:

-

Flaskless Molding Casting Line

-

Usage:

-

Molding and Casting

-

Color:

-

Green

-

Control System:

-

PLC+Touch Screen Automatic

-

Certification:

-

CE/ISO9001

Quick Details

-

Place of Origin:

-

Anhui, China

-

Machine Type:

-

Automatic

-

Brand Name:

-

Xinning

-

Voltage:

-

380V, 380V/50Hz/400V/60Hz

-

Power:

-

0

-

Dimension(L*W*H):

-

2400x1100x800(mm)

-

Weight (KG):

-

10000

-

Application:

-

steel

-

Function:

-

Molding

-

Type:

-

Fully Automatic

-

Product name:

-

Flaskless Molding Casting Line

-

Usage:

-

Molding and Casting

-

Color:

-

Green

-

Control System:

-

PLC+Touch Screen Automatic

-

Certification:

-

CE/ISO9001

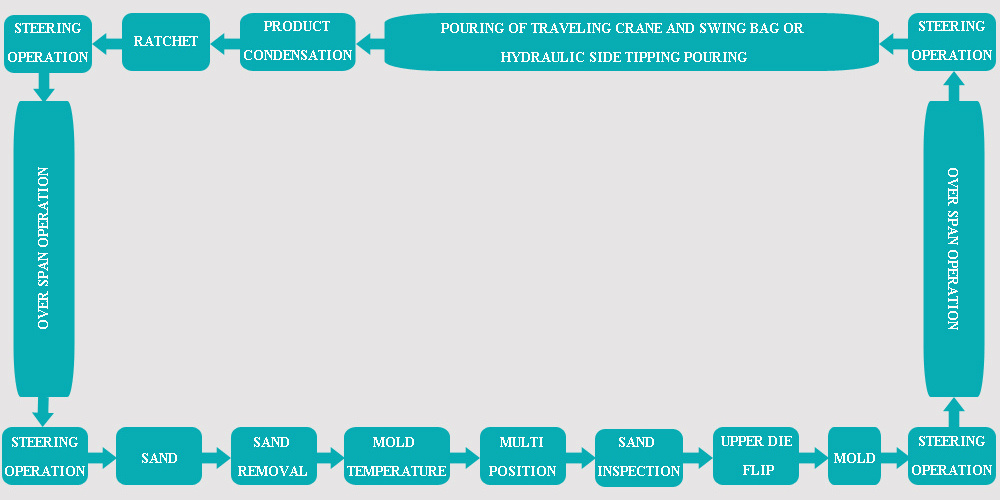

XN-TF-90II (Horizontal Parting) Specifications and Introduction detail:

After being molded, in the transportation process, the metal coated sand unavoidably leaves some loose sand into the moulding cavity caused by vibration of external force. If the loose sand fails in being purged and cleaned in time before casting, the loose sand will be involved in the metal fluid in the casting process, thus, influencing the internal side of the castings.

The current solution is to manually purge the surface of the moulding cavity before casting, so as to ensure the casting quality. Thanks to technological innovation, we created the pre-casting automatic purging motor. By the mechanical and automatic

operation, it can carry out repeated purging over the surface of moulding cavity.

By this technology and linkage, the pre-casting automatic purging motor materializes uniformly purging and cleaning over the surface of moulding cavity with stable performance and reliable operational quality.

XN-TF-90II Technical specification:

|

model |

XN-TF series |

|

Power supply/voltage |

380V/50Hz |

|

Working Pressure |

pneumatics:0.5MPa,hydraulic:6.3MPa |

|

Equipment ambient temperature |

-20℃—40℃ |

|

Equipment area |

32*10*4.5m |

|

Single-line annual output |

6000~20000 ton |

|

mould standard |

60-70(35 pairs for each of the two specifications) |

|

Position employment |

3 |

|

Total Power |

130kw |

|

Application |

Φ 40- Φ 130 Production of chromium series alloy casting ball |

Advantages over similar Products:

1) Over 12 years experience in casting equipment.

2) First and most accepted China brand.

3) Most competitive price and quality.

4) Short delivery time.

5) Instant aftersale service on line.

6) Import and Export License.

7) OEM.

Sales & after-sales services:

Warranty 1 year free.

Lifetime maintenance.

Afersale service: instant service, by on line chatting, or by phone, or by remote services or other way by negotiation.

Installation:

About Company:

Anhui Xinning Equipment Co., Ltd. , covering about 150,000 square meters, construction area of about 50,000 square meters. Is a professional research and development, manufacturing complete sets of casting equipment of science and technology enterprises. In October 2014, the Company successfully listed on the National Equities Exchange and Quotations System (Stock Code: Xinning Stock; Stock Code: 831220). The Controlling subsidiary of Anhui Xinning Energy Technology Co., Ltd. to provide customers with industrial waste heat pressure recycling and new energy power generation overall solution. Main products for energy recovery of the low-temperature waste heat recovery system, new energy thermal power of special turbine machinery. R & D strength of the company now has a "radial turbine series", "special working fluid turbine", "Organic Rankine cycle low-temperature power generation complete sets of equipment" and other proprietary intellectual property products. The "radial turbine series" technology to fill the gap and reached the international advanced level. The company upholds the "integrity, cooperation and win-win" business philosophy to create maximum customer value for the development of purpose, timely grasp of industrial energy-saving high-end technology fields and the pulse of the industry, to provide users with energy-saving overall solutions. Hardworking and sincere we are willing to go hand in hand with you, create brilliant!

Our services :

1. All iron molds coated sands casting production line have to pass the strict inspection and tested before shipping.

2. After receiving the goods, we accept your feedback the first time.

3. We could provide installation guide, if you have a need, we could give you a global service

4. provide the customized solution.

5. Our Sales are 24-hours online for our request.

6. Professional sales

7. We value every inquiry sent to us, ensure quick competitive offer.

8. We cooperate with the customer to bid tenders. Provide necessary documents.

9. We are a sales team, with all technical support from engineer team

10. All iron molds coated sands casting production line . have to pass the strict inspection and tested before shipping.

11. After receiving the goods, we accept your feedback the first time.

12. We could provide installation guide, if you have a need, we could give you a global service

13. provide the customized solution.

14. Our Sales are 24-hours online for our request.

15. Professional sales

16. We value every inquiry sent to us, ensure quick competitive offer.

17. We cooperate with the customer to bid tenders. Provide necessary documents.

18. We are a sales team, with all technical support from engineer team

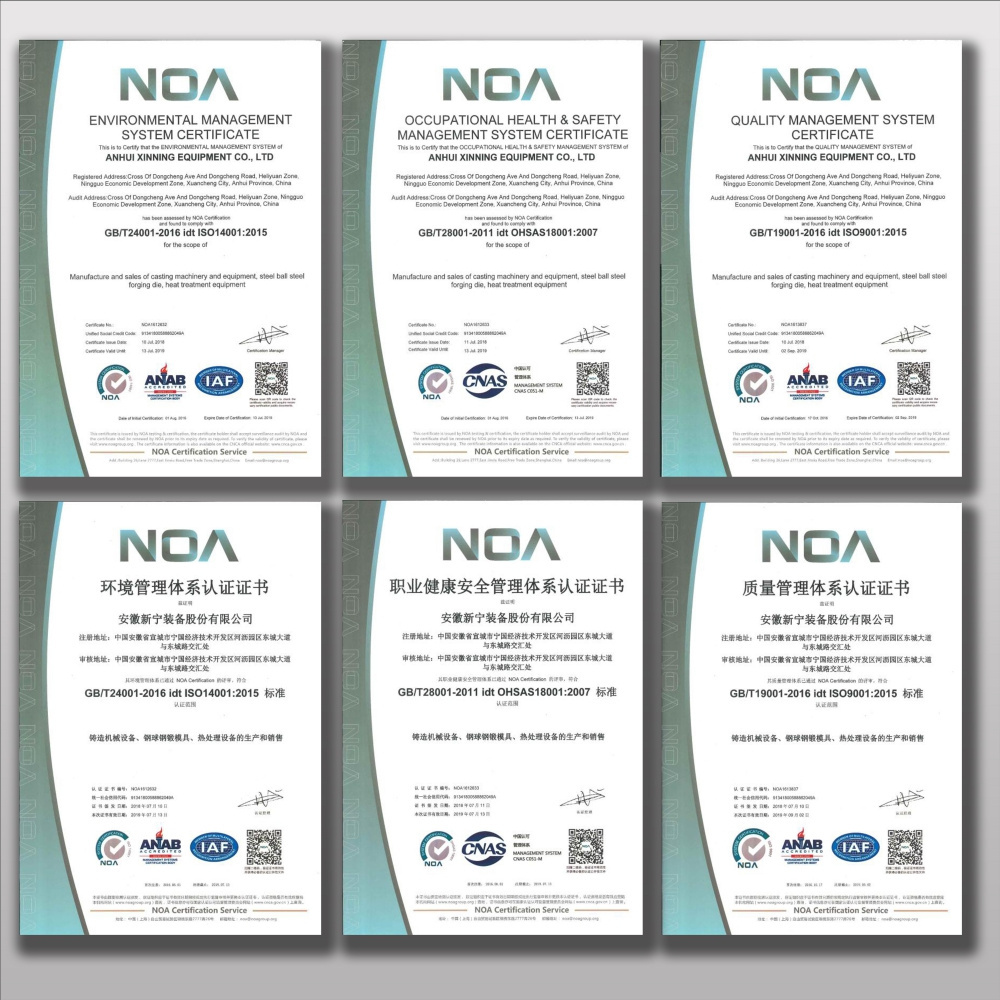

Awards and certifications:

Client Gallery:

Our Exhibition:

FAQ:

1. Are you a manufacturer?

Yes, we are a manufacturer as well as a supplier of various types of steam turbines.

2.What about the product quality?

We have testing and quality control department to ensure the quality of the products to meet national and international standards in the steam turbine industry.

3.What about the price?

We only offer a reasonable price instead of high price. Different quality and at a different price.

4. What about after sales services?

We provide after sales services based on customer demand. we provide installation and maintenance assistance abroad as we have customers around the globe. for more detail see above "Our Services".

5. What about Custom manufacturing?

Yes, we do custom manufacturing as well based on customer requirement.

Contact Information: