Work type: passive type

Structure: Steel channel welded for the basic frame

Usage:To support the coil and make the uncoiling

Loading capacity: 5 tons

Inner diameter: 450-550mm (manual adjustment)

Coil width: 1250mm

Brake system: manual brake

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China, Hebei, China

-

Brand Name:

-

ZTRFM

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

23000*1300*1500 mm

-

Weight:

-

3000 kg, 7500 kg

-

Marketing Type:

-

New Product 2023

-

Product name:

-

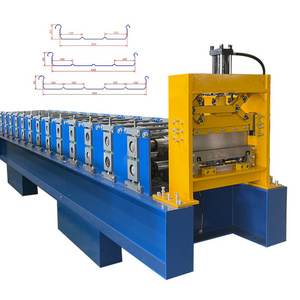

standing seam roofing sheet Machine

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

10-40M/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China, Hebei, China

-

Brand Name:

-

ZTRFM

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

23000*1300*1500 mm

-

Weight:

-

3000 kg, 7500 kg

-

Marketing Type:

-

New Product 2023

-

Product name:

-

standing seam roofing sheet Machine

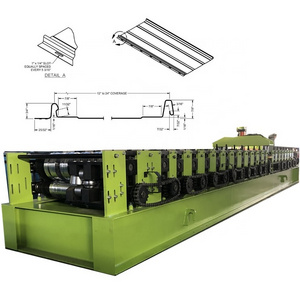

Full Automatic Smi 1.75" Snaplock Standing Seam Roof Standing Panel Roll Forming Machine For America

Design Idea:

Full Automatic Easy Operation : Whole producing line just need one person for operation.

Full Automatic Easy Operation : Whole producing line just need one person for operation.

Before Wave Shearing Design

:

For making sure the wave shape is perfect good, we

design the machine with before wave shearing. As hydraulic cutting after rolling will destroy the shape.

|

Machine Weight

|

8.2 Tons

|

|

Machine Dimension

|

7800*1200*1400 mm

|

|

Total Power

|

9 kw

|

Profile drawing for reference:

this type 1.75" SnapLock Standing Seam panel very hot sale in US.As we sold many machines to America,we have rich experience on it to confirm the finished product good and suit for market.

Processing Flow

Uncoiling → Feeding Material Into Machine →Roll Forming → Auto Cutting →Products Receiving

|

1.75" Snaplock Standing Seam Roof Standing Panel Roll Forming Machine For America

|

|

|

|

Raw Material

|

GI&PPGI&G550 GI и PPGI и G550

|

|

|

Raw material

|

Material thickness:22-24 gauge (0.3-0.8 mm)

Coil width :545 to 600mm

Effective width:430 mm

|

|

|

Machine Frame

|

350# H steel welded,Steel plate welded structure

|

|

|

Material Of Rollers

|

45# Steel,Chromed treatment, improve the hardness and prevent abrasion, anti corrosion increase of service life

|

|

|

Rolling station

|

Roller stations :16 rows

|

|

|

Diameter of shafts

|

Φ75mm solid

|

|

|

Material of shafts

|

45# STEEL,Tempering treatment to prevent deformed and improve hardness

|

|

|

Forming speed

|

20 m/min

|

|

|

Voltage

|

380V/50HZ/3P (as requested)

|

|

|

Transmission way

|

By Chains with cover

|

|

|

Main motor

|

5.5 KW

|

|

5t Manual Decolier For Free

Feeding Device

One set guiding roller

Steel plate welded platform to carry the sheet and feed into roll forming system

Feeding width is adjustable with the handle wheels

Roll Forming And Transmission Device

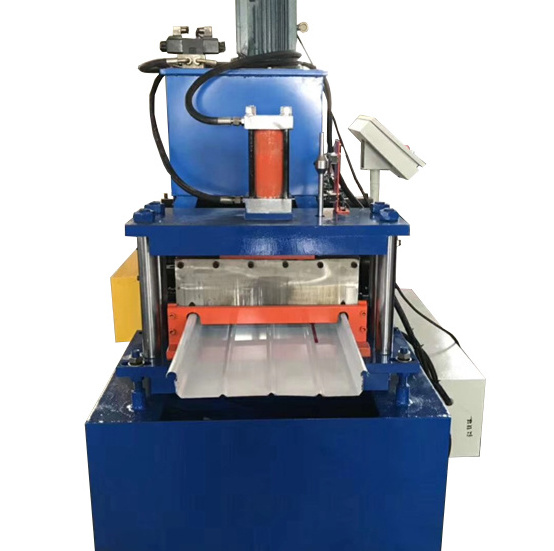

Hydraulic Cutting Device

Work type :Hydraulic cutting

Driving method :By pillar type Cylinder

Hydraulic motor power :3 kw

Cutter material :GB-Cr12 with heat treatment

Cutting length tolerance :±1mm/3m

Cutting feature :Steady and safe working condition

PLC control system

Hydraulic station

Advantage: with air-cooling system to prolong the service life.

Oil tube and wires connection: All wires will be marked by numbers or letters,So very easy to connect.

Power:4.5kw

CE(

NO.OP180719.CZIDC95

)

ISO 9001(No:ZL92090220234630)

Hot Searches