- Product Details

- {{item.text}}

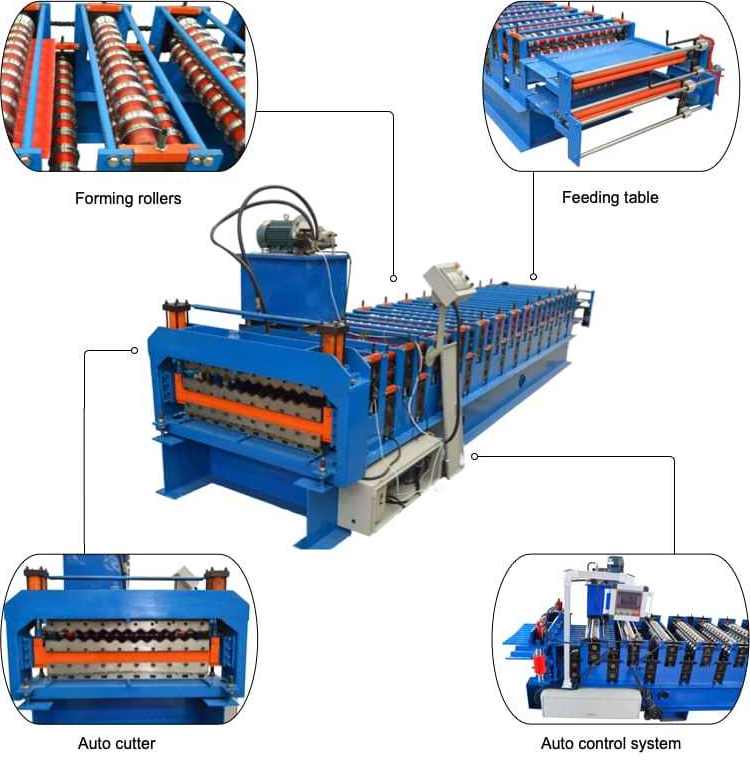

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

China

-

Brand Name:

-

TOPPO

-

Voltage:

-

380V 50Hz 3 Phase

-

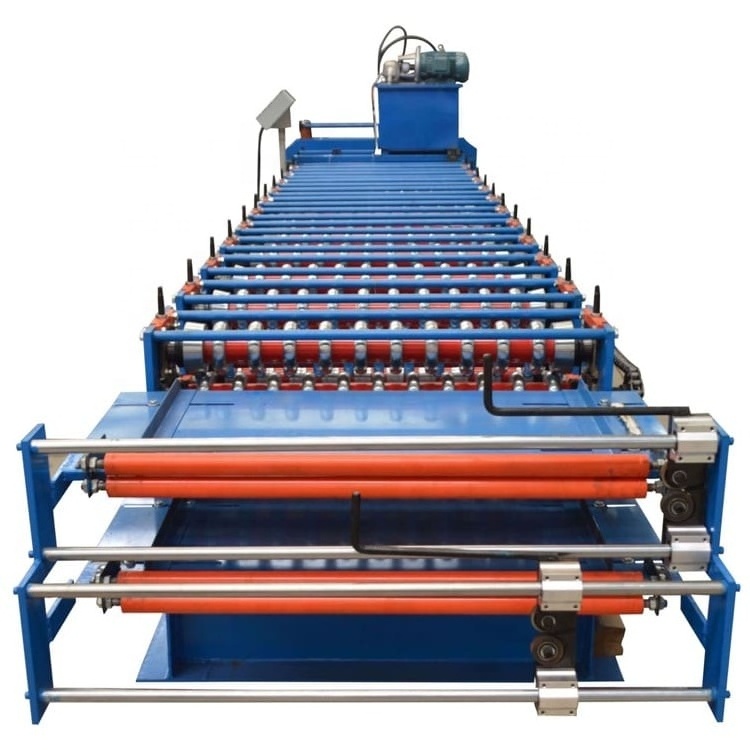

Dimension(L*W*H):

-

about 7.4*1.5*1.6 m

-

Weight:

-

about T 4.0

-

Operation Language:

-

English/Spanish/Chinese

-

Operate Style:

-

Auto/Manual

-

Motor Brand:

-

Japanese Simens

-

PLC Brand:

-

Delta/MITSUBISHI/SIEMENS

-

Cutting Blade:

-

Cr12Mov with quenched treatment

-

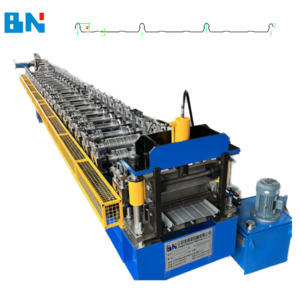

Profile:

-

as customer's requirement

-

Color of Machine:

-

blue, gray, or your required color

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

India, Kenya, Chile, Colombia, Sri Lanka, Romania, Bangladesh

-

Certification:

-

CE

Quick Details

-

Type:

-

Tile Forming Machine

-

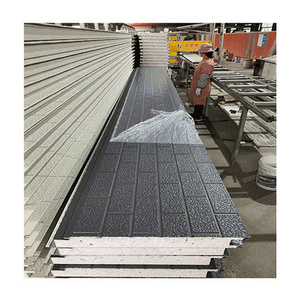

Tile Type:

-

Colored Steel

-

Production Capacity:

-

0-3m/minute

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

China

-

Brand Name:

-

TOPPO

-

Voltage:

-

380V 50Hz 3 Phase

-

Dimension(L*W*H):

-

about 7.4*1.5*1.6 m

-

Weight:

-

about T 4.0

-

Operation Language:

-

English/Spanish/Chinese

-

Operate Style:

-

Auto/Manual

-

Motor Brand:

-

Japanese Simens

-

PLC Brand:

-

Delta/MITSUBISHI/SIEMENS

-

Cutting Blade:

-

Cr12Mov with quenched treatment

-

Profile:

-

as customer's requirement

-

Color of Machine:

-

blue, gray, or your required color

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

India, Kenya, Chile, Colombia, Sri Lanka, Romania, Bangladesh

-

Certification:

-

CE

| Full Catalog |

Metal Sheet Siding Wall Panel Making Machines

| Technical Details |

|

|

||||||||||

|

|

|||||||

|

|||||||

|

|||||||

|

|

||||||

| About TOPPO |

Toppo Machinery starts roll forming machine since 1998.

We know well the requirements for the customers from different countries and have an outstanding export team who will take care of your requests. Our experts and skilled workers complete the work with great precision.

We provide an extensive line of products , including roof and wall panel machine, tile roof machine, purlin forming machine, shutter door machine, floor decking machine and other associated equipment.

Our products have been sold worldwide over 90 countries including America, the UK, Australia, India, Sri Lanka South Africa, Tanzania, Nigeria, etc.

| FAQ |

1. I am

new in this field

, do not know about the machine and do not know how to operate it.

The machine has been installed and tested well before shipping. It is easy to operate.

Normally speaking, our customer follows the instruction book and can operate the machine well.

If you need, we can also send the technician to your factory to fix the machine and train your workers.

2.

What is included

in the machine?

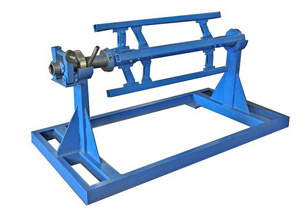

The whole line includes a manual decoiler, roll forming machine, product stand and spare parts box.

3. What's your

payment terms

?

30% as the deposit by T/T in advance, 70% as the balance payment by T/T after you inspect the machine and before delivery.

4. what is your

delivery

?

After we get down payment, we will arrange the production. About 30-45 working days for delivery.

5. How to

visit your company

?

1. Fly to Beijing Capital International Airport (PEK), we will pick you up from the exit, it is about 3 hours by car.

2. Take the bullet train to Cangzhou Xi station. We will pick you up, it is about 40 minutes to our factory.

6. Do you supply the

coils

?

No. We only make roll forming machines.

We will give you the contact information of our long-cooperate coil factory. You contact them directly. In this way, you can get the right coil and get the best price.

| Contact Us |

If you need any more information, be free to contact us. We will reply within 12 hours

|

|

Jeffrey Yao | |

| Company | Toppo Machinery Co., Ltd | |

| Jef@ ToppMachinery.com | ||

|

JeffreyYao

|

||

| +86-15631793989 | ||

| Website |

www.ToppoMachinery.com |

|

| YouTube |

www.YouTube.com/ToppoMachinery |

|