- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

COMARK

-

Dimension(L*W*H):

-

3200*2080*2300 mm

-

Weight:

-

4000kgs

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, United Kingdom, United States, France, Germany, Philippines, Brazil, Peru, Saudi Arabia, India, Mexico, Thailand, Japan, Malaysia, Argentina, South Korea, Colombia, Algeria, Romania

-

After-sales Service Provided:

-

Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Engineers available to service machinery overseas

-

Function:

-

Rinser Filler Capper

-

Processing Types:

-

juice filling

-

Filling material:

-

Flowing Liquid

-

Usage:

-

Beverage Packaging

-

Bottle type:

-

Plastic Screw Caps

-

Material:

-

SUS304/316

-

Capacity:

-

2000-30000bph

-

Name:

-

Complete Fruit Juice Processing Plant

-

Certification:

-

CE ISO SGS

Quick Details

-

Packaging Material:

-

Glass, Plastic

-

Voltage:

-

220V/380V/415V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

COMARK

-

Dimension(L*W*H):

-

3200*2080*2300 mm

-

Weight:

-

4000kgs

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, United Kingdom, United States, France, Germany, Philippines, Brazil, Peru, Saudi Arabia, India, Mexico, Thailand, Japan, Malaysia, Argentina, South Korea, Colombia, Algeria, Romania

-

After-sales Service Provided:

-

Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Engineers available to service machinery overseas

-

Function:

-

Rinser Filler Capper

-

Processing Types:

-

juice filling

-

Filling material:

-

Flowing Liquid

-

Usage:

-

Beverage Packaging

-

Bottle type:

-

Plastic Screw Caps

-

Material:

-

SUS304/316

-

Capacity:

-

2000-30000bph

-

Name:

-

Complete Fruit Juice Processing Plant

-

Certification:

-

CE ISO SGS

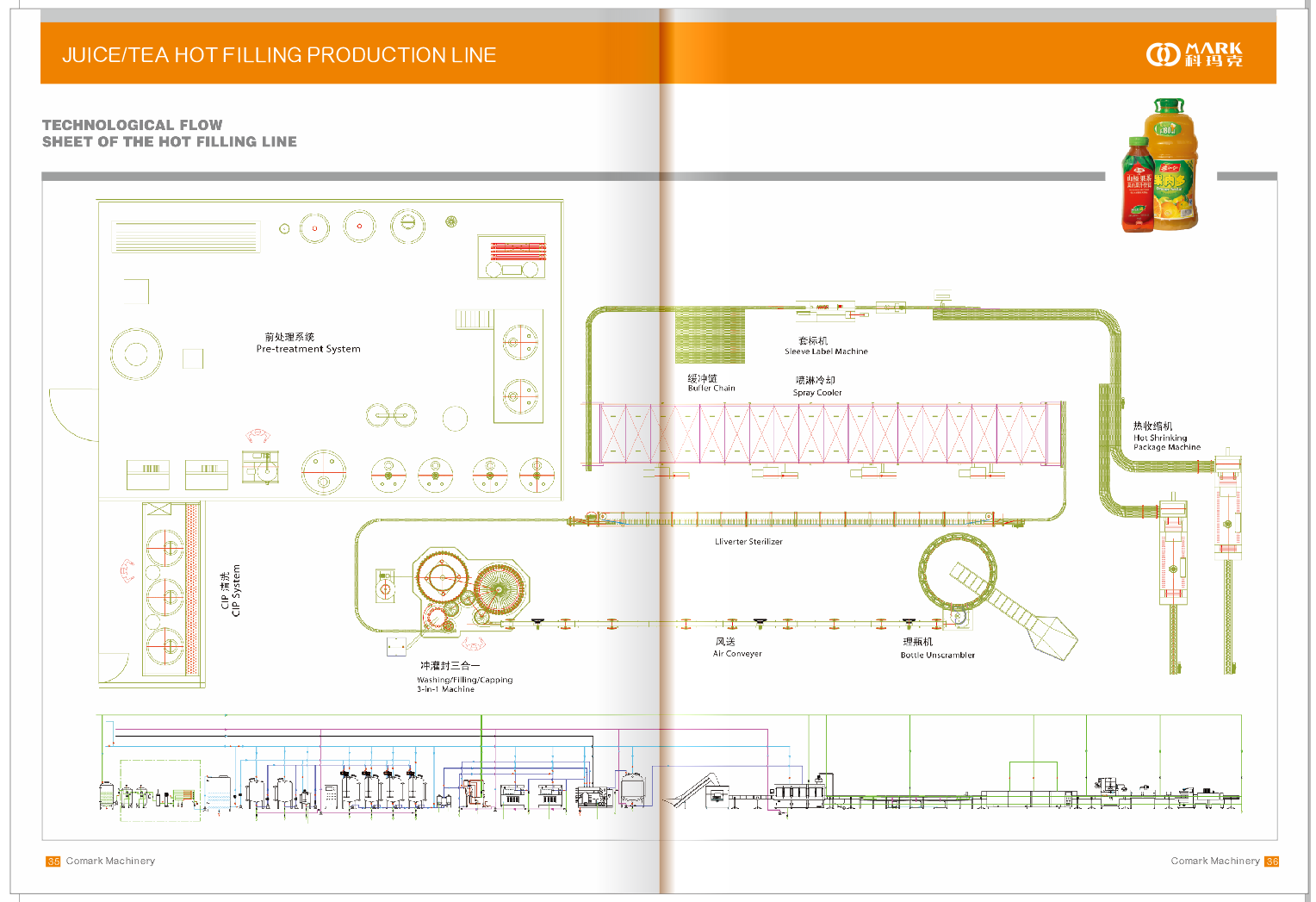

Complete Fruit Juice Processing Plant / Juice Making Machine /. Juice Plant Equipment

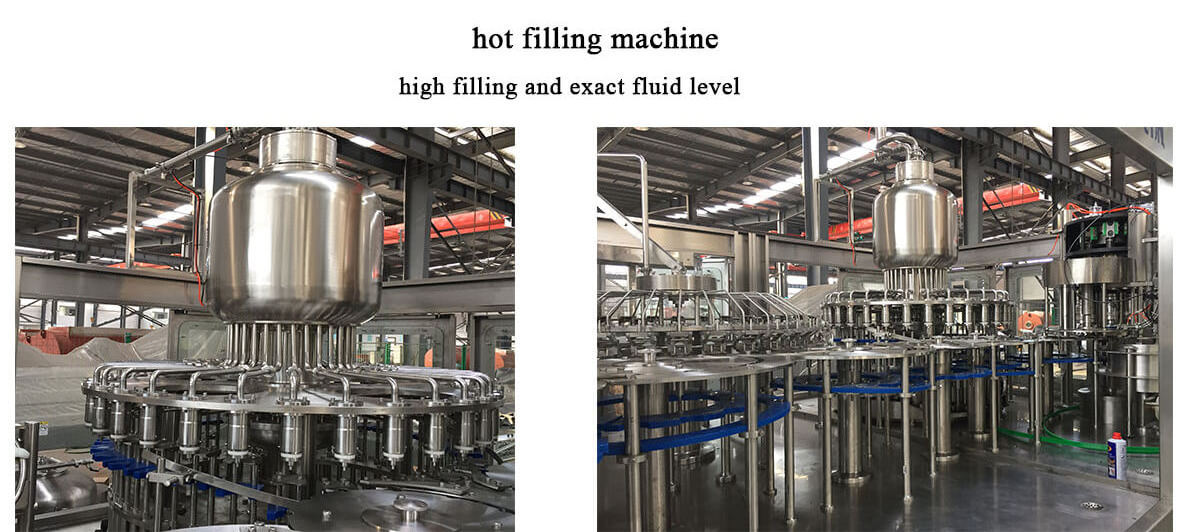

1)The machine is mainly used in the beverage filling operations. The three functions of bottle wash, fill and seal are composed in one body of the machine . The whole process is automatic. The machine is used in filling juices, mineral water and purified water in bottles made of polyester and plastics.

2)The machine can also be used in hot filling if being installed with temperature controlling device. The handle of the machine can be freely and conveniently turned to adjust the machine to fill various types of bottles.

3) The filling operation is faster and more stable because the micro pressure filling operation of the new type is adopted. There the output and benefit of the machine is higher than the machines of the same specifications. The advanced mistubishi programmed controller (PLC) is adopted to control the machine to run automatically while a transducer is used in the bottle -entering chains to adjust speeds and coordinated with the transducer of the main machine to make the operations of moving bottle forward steadily and reliably.

4) It is convenient to operate with higher automation because every part of the machine is inspected to run with photo electricity, On the bases, the filling parts of the machine can be changed into filling methods of lower vacuum.

5)The filling category of lower vacuum (Z type machine) is applicable in glass bottles, filling alcohol, soy and such like materials. The aluminum theft proof cap and plastic cap can be adopted. The machine is an idea-preferred equipment for beverage makers.

Beverage pre-treatment system:

<1> The beverage processing system applies to beverage processing for hot filling line and CSD filling line.

<2> product's scope hot water system, sugar dissolving system ( simple syrup system ), concentrate system, blending system (final syrup system), CIP system, extraction system, kind of storage tank / valves / pipe / fittings, UHT system (plate / tubular type), and carbo-cooler / mixer (manual / automatic).

Tube UHT Sterilizer.

The tube(pipe) sterilize machine can take hot process on the liquid foods and beverage.

Bottle Inverse Sterilizer Machine.

It is mainly used in sterilizing PET bottle mouth and inside surface of caps. in which haven't been disinfected by themal tea,fruit juice which having been filed in PET bottle.

Continuous Spraying Sterilizer.

It adopts warm water to preheat, sterilize with recycling hot water, recycling warm water to pre-cool, and cooling water to cool; It is with the advantage of sterilizing temperature automatic control, and adjustable sterilizing time.

Automatic labeling machine.

It adopts double driving structure which is a new and advanced driving device for the thermal shrink sleeve machine, that is, four-wheel driving, self-centering and balanced pressure of four wheels. It can achieve the good effect of transmission of labels smoothly, stably and rapidly.

PE film packaging machine.

It adopts the photoelectric sensor to detect online, gather signals which are controlled by PLC, and adopts piston as executable element, to realize product conveying, combination, film wrapping, cutting, heat& shrink, cool and finally get the finished product.

Installation service

When you finish the Preparation conditions,our fast and professional aftersales service engineer team will go to your factory to install the machine,give you the operating manual,and train your employee until they can operate the machine well.

The sample service

1.We can send you the video of the running machine.

2.You are welcome to come to visit our factory,and see the machine running.

Customized service

1.We can design the machines according your requirements(materil,power,filling type,the kinds of the bottles,and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

After-sales service

1.We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly

2.When you finish the Preparation conditions,our fast and professional aftersales service engineer team will go to your factory to install the machine,give you the operating manual,and train your employee until they can operate the machine well.

3. We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

4.We provide one year warranty

5.Well-trained & experienced staff are to answer all your inquiries in English and Chinese

6 .24 hours for engineer response (all services part 5days in customer hand by Intl' courier).

7 .12 Months guarantee and life-long technical support.

8.Your business relationship with us will be confidential to any third party.

9. Good after-sale service offered, please get back to us if you got any questions.

Quality Control

We have the single quality department,that make sure the material of the raw materials is good,and ensure the machine running smoothly.

If you want to know more information about the product,You can send an inquiry, we will solve any of your problems and send you running vedio.