- Product Details

- {{item.text}}

Quick Details

-

Power:

-

according capacity

-

Weight:

-

according capacity

-

Dimension(L*W*H):

-

according capacity

-

Year:

-

2020

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support

-

screw quantity:

-

2

-

temperature:

-

adjustable

-

Application:

-

corn flakes processing line

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Turkey, Morocco, Algeria

-

Certification:

-

CE CIQ

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Eagleextruder

-

Voltage:

-

according your requirement

-

Power:

-

according capacity

-

Weight:

-

according capacity

-

Dimension(L*W*H):

-

according capacity

-

Year:

-

2020

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support

-

screw quantity:

-

2

-

temperature:

-

adjustable

-

Application:

-

corn flakes processing line

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Turkey, Morocco, Algeria

-

Certification:

-

CE CIQ

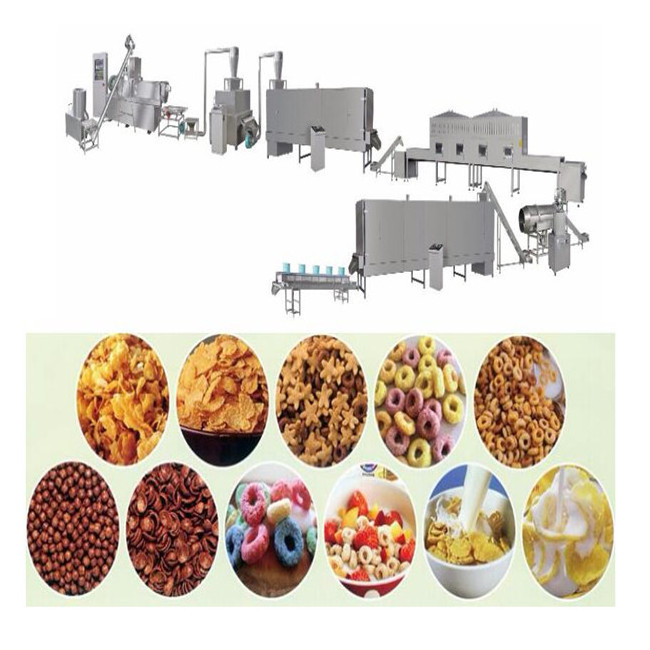

Product show

Corn flakes breakfast cereals making production line

General Introduction

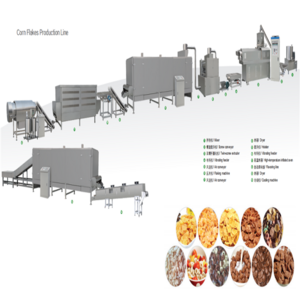

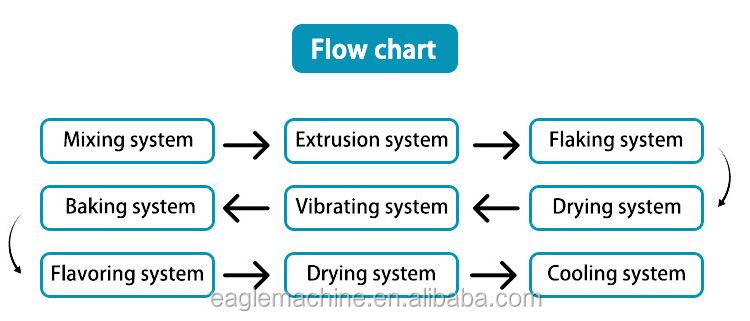

This production line is developed and manufactured on the basis of the international advanced extruder technology, which is named corn flakes (breakfast cereals) production line. Its technology performance and quality can be reached international advanced level,consisting of mixing, extruding, inflating, flaking, and drying. The whole production is done at one stream under full automatically working.

Corn powder is the major material in the production line. Extruding & shaping workmanship enables the appearance of the products to look better and natural and taste delicious and crisp, without cracking. The line is characterized by proper design, stable performance, and high automation. Main engine adopts advanced frequency & speed controlling technology, so it can save energy and be efficient. Accurate parameter and fine workmanship flow ensure stable quality of the products, which are integration of traditional arts and modern technology.

This production line is developed and manufactured on the basis of the international advanced extruder technology, which is named corn flakes (breakfast cereals) production line. Its technology performance and quality can be reached international advanced level,consisting of mixing, extruding, inflating, flaking, and drying. The whole production is done at one stream under full automatically working.

Corn powder is the major material in the production line. Extruding & shaping workmanship enables the appearance of the products to look better and natural and taste delicious and crisp, without cracking. The line is characterized by proper design, stable performance, and high automation. Main engine adopts advanced frequency & speed controlling technology, so it can save energy and be efficient. Accurate parameter and fine workmanship flow ensure stable quality of the products, which are integration of traditional arts and modern technology.

For breakfast cereals in different shapes and textures, e.g. puffed rice, cornflake type shapes, rice crispies, honey bears etc.

Extrusion raw materials: Maize, wheat, rice, salt, sugar, malt, milk powder, glucose, honey etc.

Coating raw materials:Sugar, chocolate, cocoa powder, milk powder, yoghurt powder, malt, dried fruits,yoghurt etc.

Extrusion raw materials: Maize, wheat, rice, salt, sugar, malt, milk powder, glucose, honey etc.

Coating raw materials:Sugar, chocolate, cocoa powder, milk powder, yoghurt powder, malt, dried fruits,yoghurt etc.

Specification

|

Model

|

Capacity for breakfast cereals

|

capacity for corn flakes

|

|

DP65 twin screw extruder corn flakes line

|

100-150kg/h

|

100-120kg/h

|

|

DP70 twin screw extruder corn flakes line

|

200-250kg/h

|

150-200kg/h

|

|

DP75 twin screw extruder corn flakes line

|

300-400kg/h

|

200-300kg/h

|

|

DP100 twin screw extruder corn flakes line

|

600-800kg/h

|

400-600kg/h

|

|

DP120 twin screw extruder corn flakes line

|

800-1000kg/h

|

600-700kg/h

|

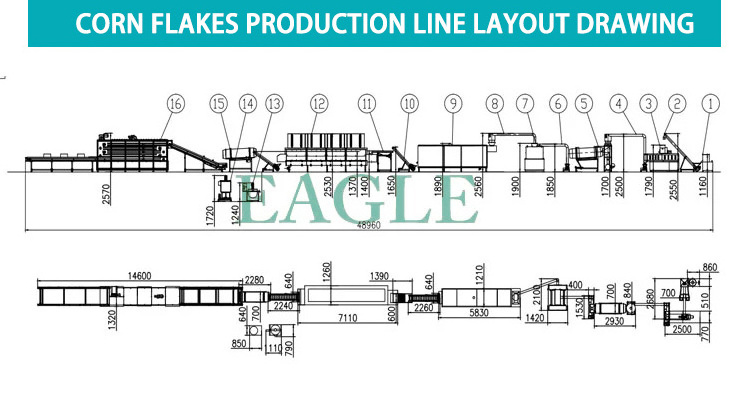

Main equipment list

Hot Searches