- Product Details

- {{item.text}}

Quick Details

-

Shape:

-

Powder , lumps

-

Material:

-

Ag

-

Chemical Composition:

-

Nb:60%&65%

-

grade:

-

BLT-Ag-01-10

-

Average particle size range (μm):

-

2 to 75

-

Specific surface area (m2/g):

-

0.2 to 1.4

-

Bulk density (g/ml):

-

0.6 to 5.0

-

Tap Density (g/ml):

-

1 to 6

-

Ablation (550℃):

-

≤ 0.4%

-

color:

-

Silver White

-

Main Market:

-

Woldwide

-

silver purity:

-

≥ 99.99%

-

Delivery Time:

-

7-15 Work Days

Quick Details

-

Application:

-

conductive paste / ink

-

Place of Origin:

-

Henan, China

-

Model Number:

-

BFM

-

Shape:

-

Powder , lumps

-

Material:

-

Ag

-

Chemical Composition:

-

Nb:60%&65%

-

grade:

-

BLT-Ag-01-10

-

Average particle size range (μm):

-

2 to 75

-

Specific surface area (m2/g):

-

0.2 to 1.4

-

Bulk density (g/ml):

-

0.6 to 5.0

-

Tap Density (g/ml):

-

1 to 6

-

Ablation (550℃):

-

≤ 0.4%

-

color:

-

Silver White

-

Main Market:

-

Woldwide

-

silver purity:

-

≥ 99.99%

-

Delivery Time:

-

7-15 Work Days

|

Silver flake

|

|

|

|

|

||||

|

Trademark

|

Average particle size range (μm)

|

Specific surface area (m2 /g)

|

Bulk density (g/mL)

|

Tap Density (g/mL)

|

||||

|

BLT-PAg -01

|

9.00 ~ 11.00

|

1.50 ~ 2.50

|

0.60 ~ 0.80

|

1.20 ~ 1.60

|

||||

|

BLT-PAg -02

|

8.00 ~ 10.00

|

1.50 ~ 2.50

|

0.80 ~ 1.00

|

1.60 ~ 2.00

|

||||

|

BLT-PAg -03

|

7.00 ~ 9.00

|

1.50 ~ 2.50

|

1.00 ~ 1.20

|

2.00 ~ 2.50

|

||||

|

BLT-PAg -04

|

6.00 ~ 8.00

|

1.00 ~ 1.50

|

1.20 ~ 1.40

|

2.00 ~ 3.00

|

||||

|

BLT-PAg -05

|

6.00 ~ 8.00

|

1.50 ~ 2.50

|

1.40 ~ 1.60

|

2.00 ~ 3.50

|

||||

|

This series of silver powder is mainly used for conductive coatings, conductive fillers for polymer conductive pastes. Differentpowders can be mixed according to oil absorption and conductivity requirements.

|

|

|

|

|

||||

Product Introduction

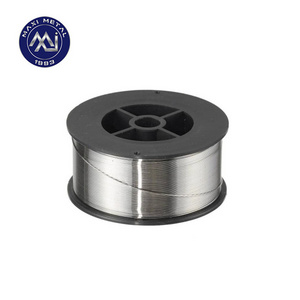

Silver-based solder (environmentally friendly)

Silver-based solder is an alloy mainly composed of silver or silver-copper. This kind of solder has excellent process performance, low melting point, good wettability and caulking performance, and excellent strength, plasticity, electrical conductivity and corrosion resistance. A class of brazing materials with a wide range of applications.

Flux-cored silver electrode, coated silver electrode, flux-cored welding ring, coated welding ring, flat wire, welding ribbon, powder, paste, granule, ring, special-shaped ring and other forms.

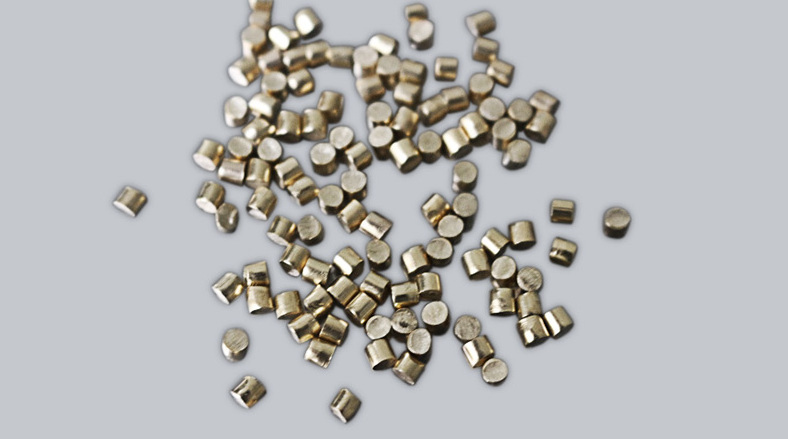

Silver-based solder (phosphorus)

Silver-copper-phosphorus solder is the addition of silver (Ag) to the phosphorus-copper alloy, which reduces the melting point of the solder and improves the plasticity, strength, toughness and wettability of the solder. During brazing, the heating time should be as short as possible, and the joint may be bright gray, which can be restored to copper color after being immersed in 5%-10% dilute sulfuric acid for pickling.

Coated welding rod, Coated welding ring, Granule, Solder paste, Powder, Conventional welding wire, Granule, Welding rod, Welding ring, Welding ribbon, Flat bar, Special-shaped ring, etc.

Copper base solder

Brass brazing filler metal has good plasticity and high melting point, and can be completed by flame brazing, induction brazing and other methods. Due to the high zinc content, the brazing amount contains a small amount of silicon, and overheating should be avoided during brazing to reduce the effect of zinc volatilization on the compactness of the brazing seam.

Flux-cored welding wire, coated welding wire, flux-cored welding ring, coated welding ring, conventional welding rod, powder, paste, welding ring, welding strip, flat bar, special-shaped ring, etc.

Copper-Based Solder (Containing Phosphorus)

The content of phosphorus is the key to determine the melting range and performance. It can be used as a self-flux in the welding of copper and copper without additional flux, and has good fluidity. However, when brazing brass and bronze, it needs to be combined with flux. According to market demand, phosphor bronze solders with various composition ratios can be provided.

Coated welding rod, coated welding ring, conventional welding wire, welding rod, powder, paste, welding ring, welding strip, flat bar, special-shaped ring, etc.

Aluminum flux cored solder

Aluminum flux-cored welding wire is a composite brazing material whose outer skin is aluminum-silicon alloy and inner layer is white fluoride flux. The white flux is non-hygroscopic, non-corrosive, and does not require cleaning after welding.

Ring wire diameter range: 0.8mm-2.5mm, ring inner diameter range: 4mm-50mm. Oval, square, U-shaped and other different physical shapes can be customized according to customer needs.

Copper and aluminum flux cored solder

Copper-aluminum flux-cored wire is a composite brazing material whose outer skin is zinc-aluminum alloy and the inner layer is white fluoride flux. The white flux is non-hygroscopic, non-corrosive, and does not require cleaning after welding.

Ring size: wire diameter range: 0.8mm-2.5mm; ring inner diameter range: 4mm-50mm. There are wires, straight bars, welding rings, etc. Special-shaped welding rings have different physical shapes such as oval, square, U-shaped, etc., which can be customized according to customer needs.

Products Description

Aircraft Parts Welding Success Stories

Serrated Welding Success Stories

Successful case of copper pipe welding

Brazing Processing Cooperation Successful Case Show

Production Equipment

FAQ

Q1. Which products are your best-selling products?

A: Phosphor copper brazing alloy, silver-based brazing alloy, brass brazing alloy; solder tab; solder ring

Q2. Can you provide customized products?

A: Yes. We have a professional R&D department, if you have any special needs for products, please contact us for the best cooperation.

Q3. How long is the delivery time?

A: Usually 7-15 days after we receive the prepayment.

Q4: What about the payment?

A:We accept T/T, and L/C for the large quantities order, and Western union and Paypal will be accept for the small quantities order.

Q5: What is your quality control process?

A:

We do 100% testing for any of products before the order has been delivered.

Q6:What kind of services do you provide?

A:We provide hourly online service, welcome your consultation and look forward to working with you.

Hot Searches