Name:

Date code

Machine can print date code or series letter on tube tail, also it's very easy to replace the code.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

AC220V 50/60HZ

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LOOKER

-

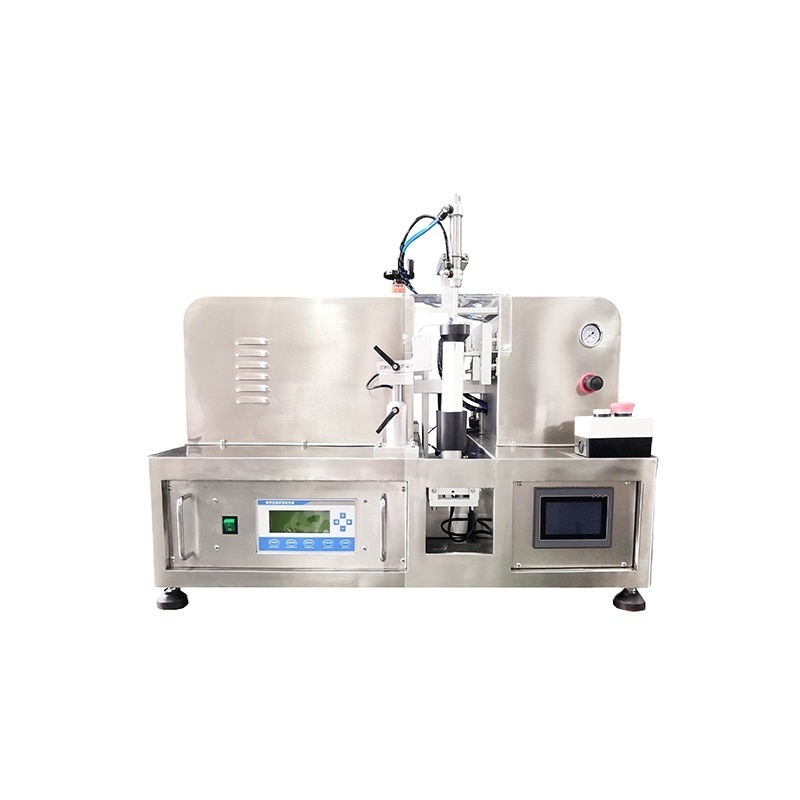

Dimension(L*W*H):

-

860*620*610mm

-

Weight:

-

70 KG

-

Body Material:

-

304 Stainless steel

-

System:

-

Intelligent frequency tracking

-

Control board:

-

PLC

-

Sealing power:

-

Ultrasound

-

Guarantee:

-

1 year

-

Date code printing:

-

one set free of charge

-

Tube diameter:

-

10~50 mm

-

Filling range:

-

10~250ml (customization)

Quick Details

-

Packaging Type:

-

plastic tube

-

Packaging Material:

-

Plastic

-

Driven Type:

-

Pneumatic

-

Voltage:

-

AC220V 50/60HZ

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LOOKER

-

Dimension(L*W*H):

-

860*620*610mm

-

Weight:

-

70 KG

-

Body Material:

-

304 Stainless steel

-

System:

-

Intelligent frequency tracking

-

Control board:

-

PLC

-

Sealing power:

-

Ultrasound

-

Guarantee:

-

1 year

-

Date code printing:

-

one set free of charge

-

Tube diameter:

-

10~50 mm

-

Filling range:

-

10~250ml (customization)

Machine Application

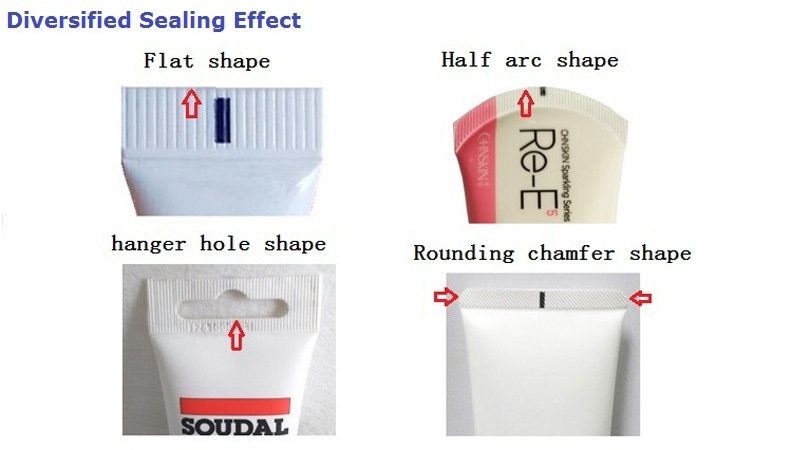

The high frequency vibration acts on the two surfaces of the plastic, and the heat generated by the vibration causes these two surfaces to be welded together tightly, the strength of welding area is the same as other area of the plastic. No need adhesive or heating, Replace the traditional hot pressing or bonding process, Low cost , no pollution and no damage to plastic tube.

|

Model

|

LK-2020T

|

|

Power supply

|

AC220V 50/60Hz

|

|

POWER

|

2000W

|

|

Frequency

|

20KHZ

|

|

Tube length

|

50~300mm

|

|

Tube diameter

|

10~50mm

|

|

Speed

|

10-20pcs/min

|

|

Machine size

|

860*620*610mm

|

|

Net weight

|

70KG

|

1. To replace the traditional welding or bonding process, low cost, clean pollution-free and does not damage the plastic tube.

2. Intelligent automatic frequency tracking system, which can recognize the vibration frequency of the ultrasonic system automatically, so as to effectively protect the mold. Large output, small noise, stable performance, long life.

3. Machine is equipped with Airtac cylinders and Airtac magnetic valves, stable performance.

4. High welding strength, Good sealing performance, the strength of welding area is same as other area of the plastic.

5. Stable welding process, easy operation, easy maintenance.

6. Precision IC control circuit, automatic overload protection system.

7. Adopting PLC controller, easy to operate, auto-protecting system can avoid the damage caused by improper operation.

8. Four points balance adjustment, easy to adjust the welding head.

9. Aluminum/titanium radial pole, sonic, strong stability.

10. Stepper motor is used for orientation, the speed can be adjusted to improve the accuracy.

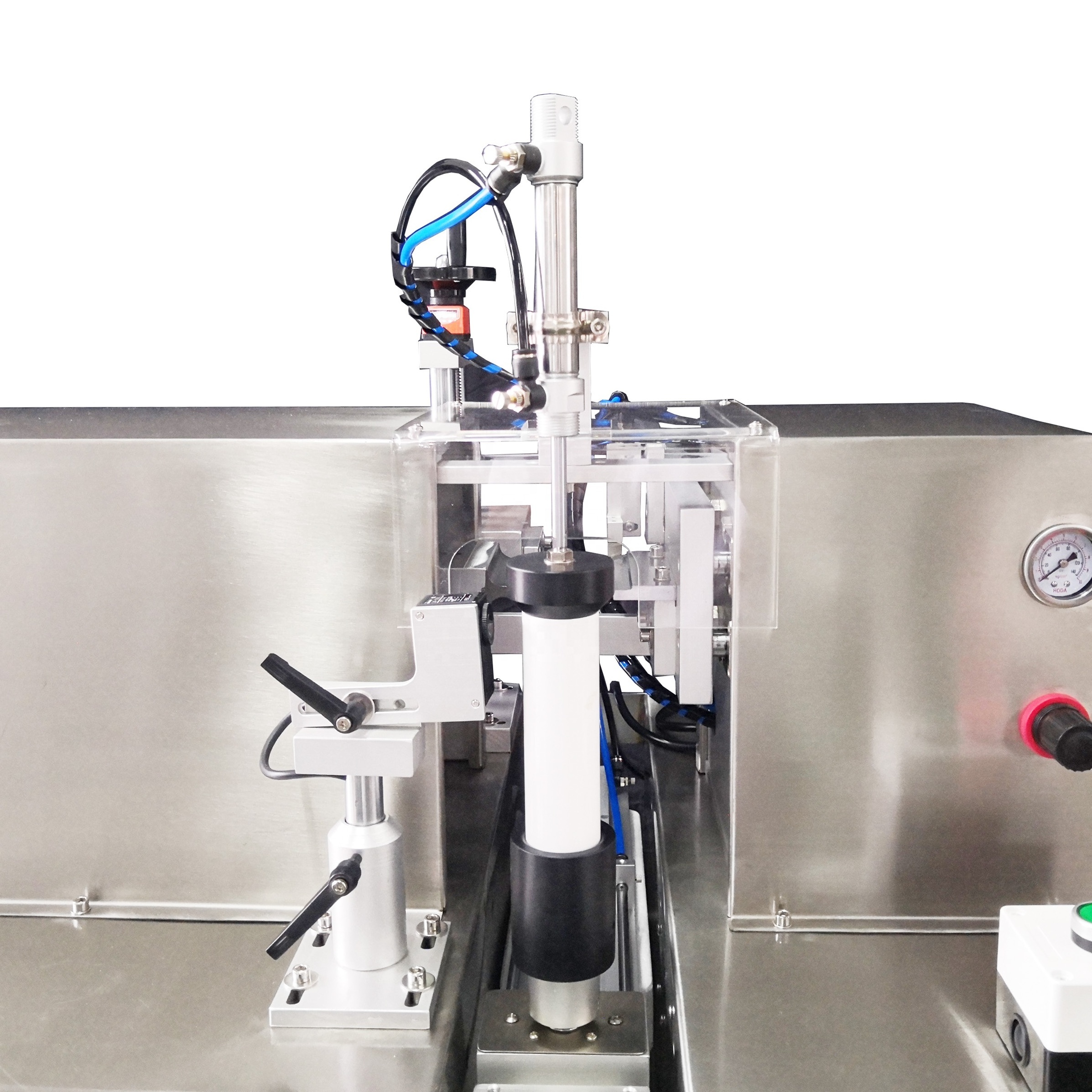

Machine Parts

Machine Parts

Name:

Sealing mould

Mould is made of aluminum and specially treated.Front mould is chrome plated which make it harder and wear-resisting.

Ultrasonic system

Intelligent automatic frequency tracking system, which can recognize the vibration frequency of the ultrasonic system automatically , so as to effectively protect the mold. Large output, small noise, stable performance, long life.

Auto Tube Orientation

.

1.Pre-Sales Service

1.Operation manual provided.

2. Assemble video, Working video, Setting video.

3.Machine operation video is easy for customer to know how to opearate the machine.

2.Customer visiting factory service.

Many customers from all over the world visit our factory every year.We test machines for them at our factory ,tell them what products our machine can make and the machine working princeple .You are welcome to visit our factory any time.

3.After-Sales Service

Our senior engineers are skillful and fluent in English.They have rich oversea experiences and are available to oversea services for our customers anytime .Below with some pictures our engineers trained customers how to install and operate the machines.