- Product Details

- {{item.text}}

Quick Details

-

Width of bed (mm):

-

55 mm

-

Spindle Motor Power(kW):

-

18.5/22

-

Max. Turned Length (mm):

-

610

-

Travel (X Axis)(mm):

-

420 mm

-

Travel (Z Axis)(mm):

-

620 mm

-

Positioning Accuracy (mm):

-

±0.007

-

Place of Origin:

-

Jiangsu, China

-

Dimension(L*W*H):

-

3600*1800*3800

-

Brand Name:

-

Samax

-

Model Number:

-

SZ550E

-

Voltage:

-

380V

-

Weight (KG):

-

12500

-

Marketing Type:

-

Hot product 2023

Quick Details

-

Type:

-

VERTICAL

-

Max. Length of Workpiece (mm):

-

610

-

Max. Spindle Speed (r.p.m):

-

2000 r.p.m

-

Width of bed (mm):

-

55 mm

-

Spindle Motor Power(kW):

-

18.5/22

-

Max. Turned Length (mm):

-

610

-

Travel (X Axis)(mm):

-

420 mm

-

Travel (Z Axis)(mm):

-

620 mm

-

Positioning Accuracy (mm):

-

±0.007

-

Place of Origin:

-

Jiangsu, China

-

Dimension(L*W*H):

-

3600*1800*3800

-

Brand Name:

-

Samax

-

Model Number:

-

SZ550E

-

Voltage:

-

380V

-

Weight (KG):

-

12500

-

Marketing Type:

-

Hot product 2023

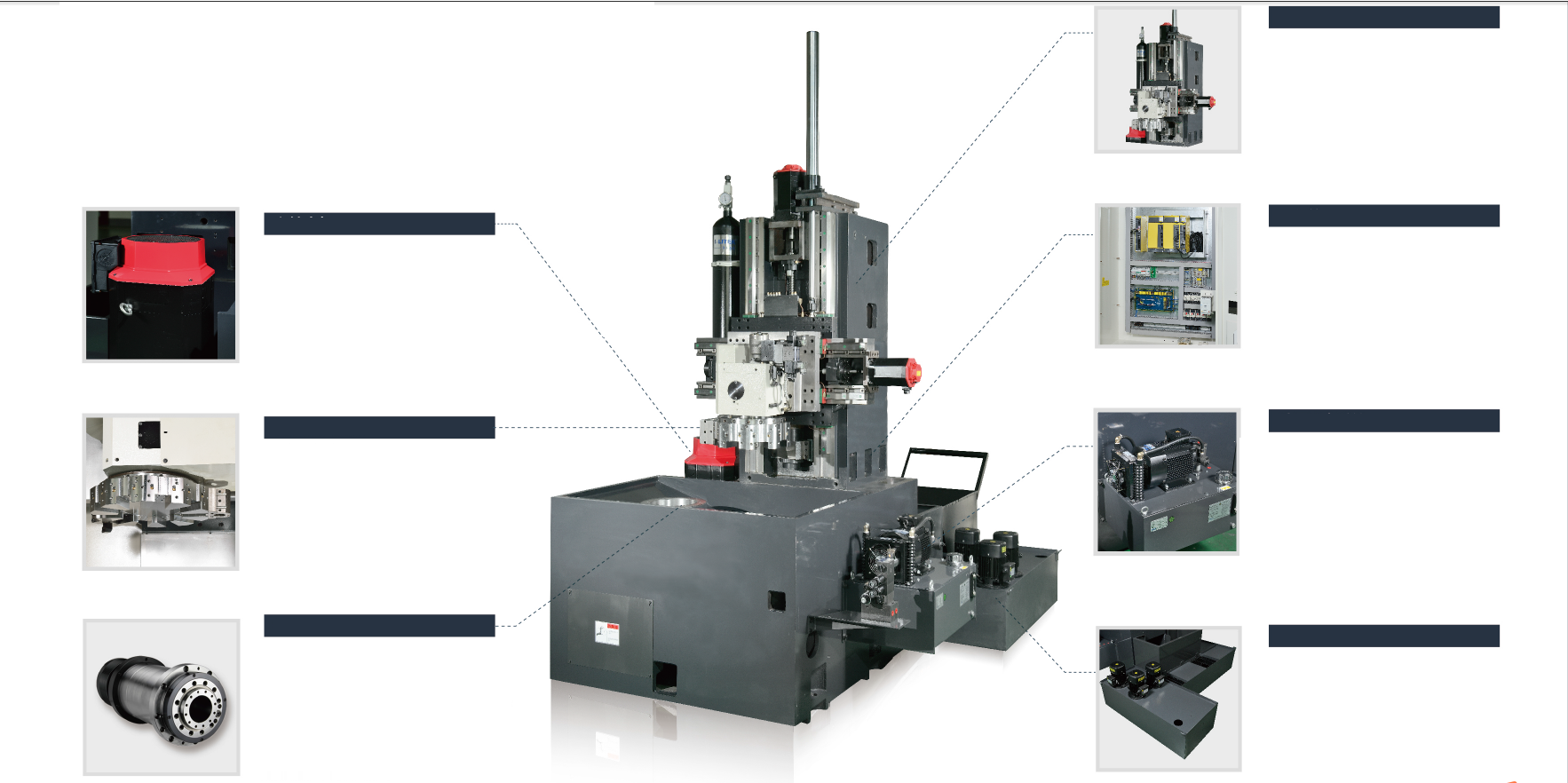

Ⅰ. Machine Tool Characteristics

1. This machine tool is designed and manufactured using high-grade cast iron and box-shaped structure. It has been properly annealed to eliminate internal stress, and the material is tough. In addition, the box-shaped structure design and high-rigidity body structure make the machine have sufficient rigidity and strength. The machine exhibits the characteristics of heavy-duty cutting capability and high reproduction accuracy.

2. The base and spindle box are an integrated box-shaped structure, using thick rib walls and multi-layer rib wall designs, which can effectively suppress thermal deformation and withstand static and dynamic distortion and deformation stress, ensuring high rigidity and high stability of the bed.

3. The column adopts a honeycomb symmetrical box structure, and the interior is designed with thick-walled ribs and internal stress-relieving round hole ribs, which can provide strong support for the slide table during heavy cutting, ensuring the high rigidity and high precision of the bed.

4. High-precision, high-rigidity spindle head : This machine adopts FANUC high-power spindle servo motor (power 18.5/22 KW ).

5. The spindle bearing uses SKF NSK series bearings . This bearing provides super strong axial and radial loads and can ensure long-term heavy cutting . It has excellent precision, stability, low friction, good heat dissipation and spindle support rigidity.

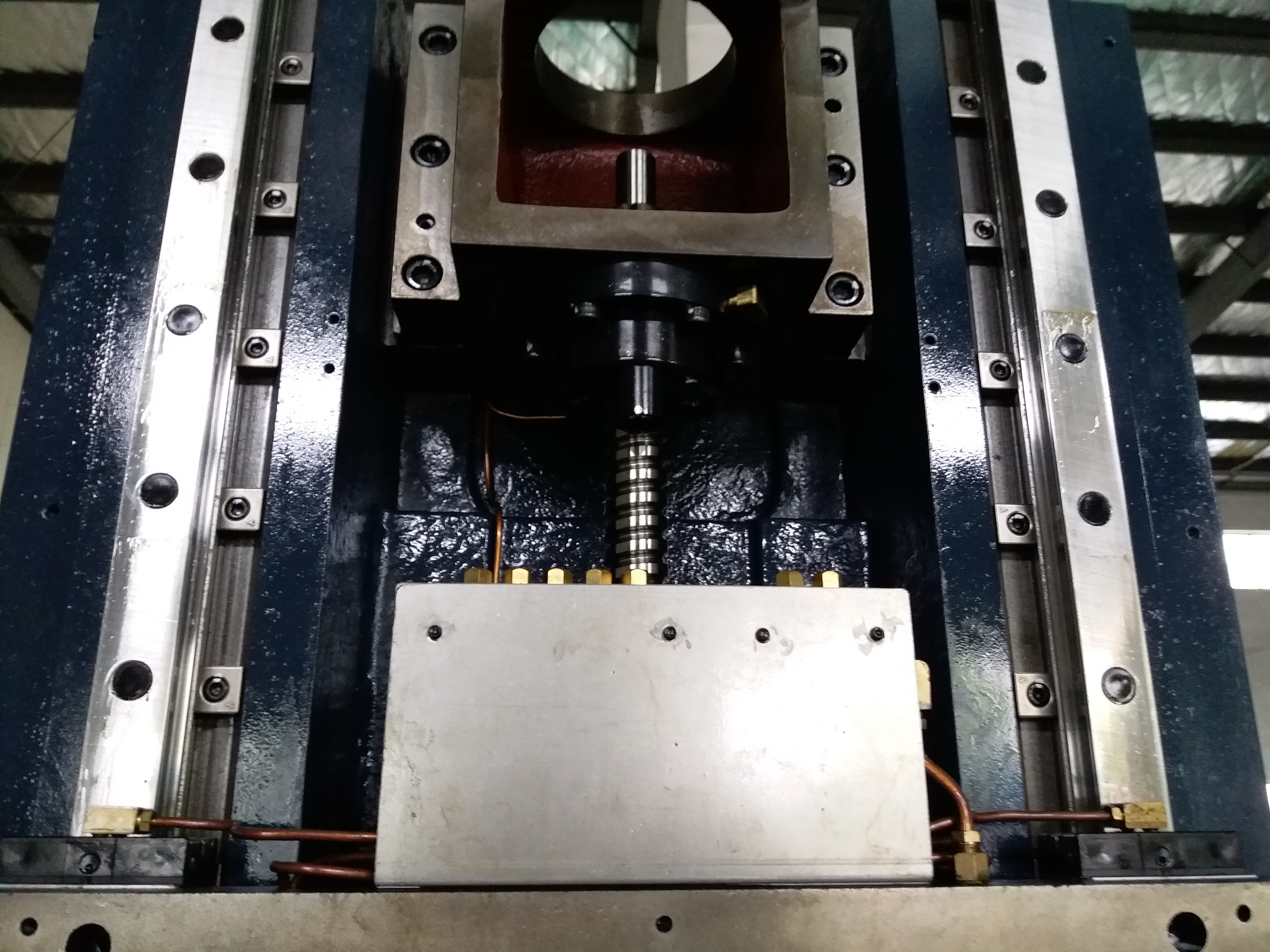

6. X/Z axis : It adopts FANUC AC servo motor and large-diameter ball screw ( accuracy level C3 , using pre-tension method , which can eliminate thermal expansion and improve rigidity ) for direct transmission. There is no cumulative error of belt transmission. The repetition and positioning accuracy is accurate . It is used for support . The bearings adopt high-precision angled ball bearings.

7. The X/Z axis adopts super heavy-duty linear slide rails with high rigidity and low friction coefficient, which can achieve high-speed feed, reduce guide rail wear, and extend the accuracy of the machine tool. This kind of linear slide has a small friction coefficient and high quick response, which can demonstrate high machining accuracy requirements and can also achieve high-load cutting.

8. Lubrication system : This machine's automatic decompression lubrication system collects oil during the collection, and uses an advanced depressurization intermittent oil supply system to provide timely and appropriate oil supply to each lubrication point in a timed, quantitative, constant pressure, and individual manner to ensure Every lubrication position is indeed lubricated, so that the machine can operate for a long time without any worries.

9. Full-covered sheet metal : Under today's strong requirements for environmental protection and operator safety considerations, sheet metal design focuses on beautiful appearance, environmental protection and ergonomics. The fully sealed sheet metal design completely prevents cutting fluid and cutting chips from splashing outside the machine tool, keeping the surroundings of the machine tool clean. And there are cutting fluid flushing bottom bed designs on both sides of the machine tool to prevent cutting chips from staying on the bottom bed as much as possible.

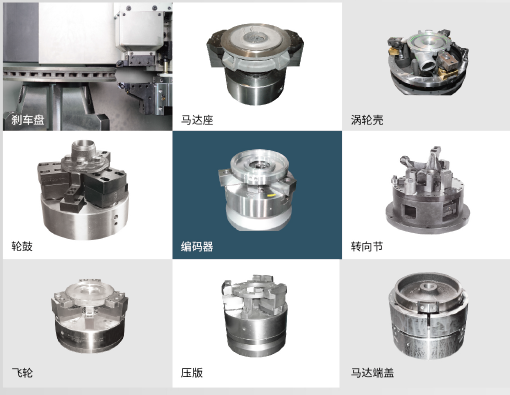

Ⅱ.Standard configuration

1. CNC system FANUC 0i-TF Plus

2. Horizontal 10-station turret

3. End face tool holder (2 pieces), inner diameter tool holder (2 pieces)

4. Spindle bearing inner diameter ø160mm (A2-11)

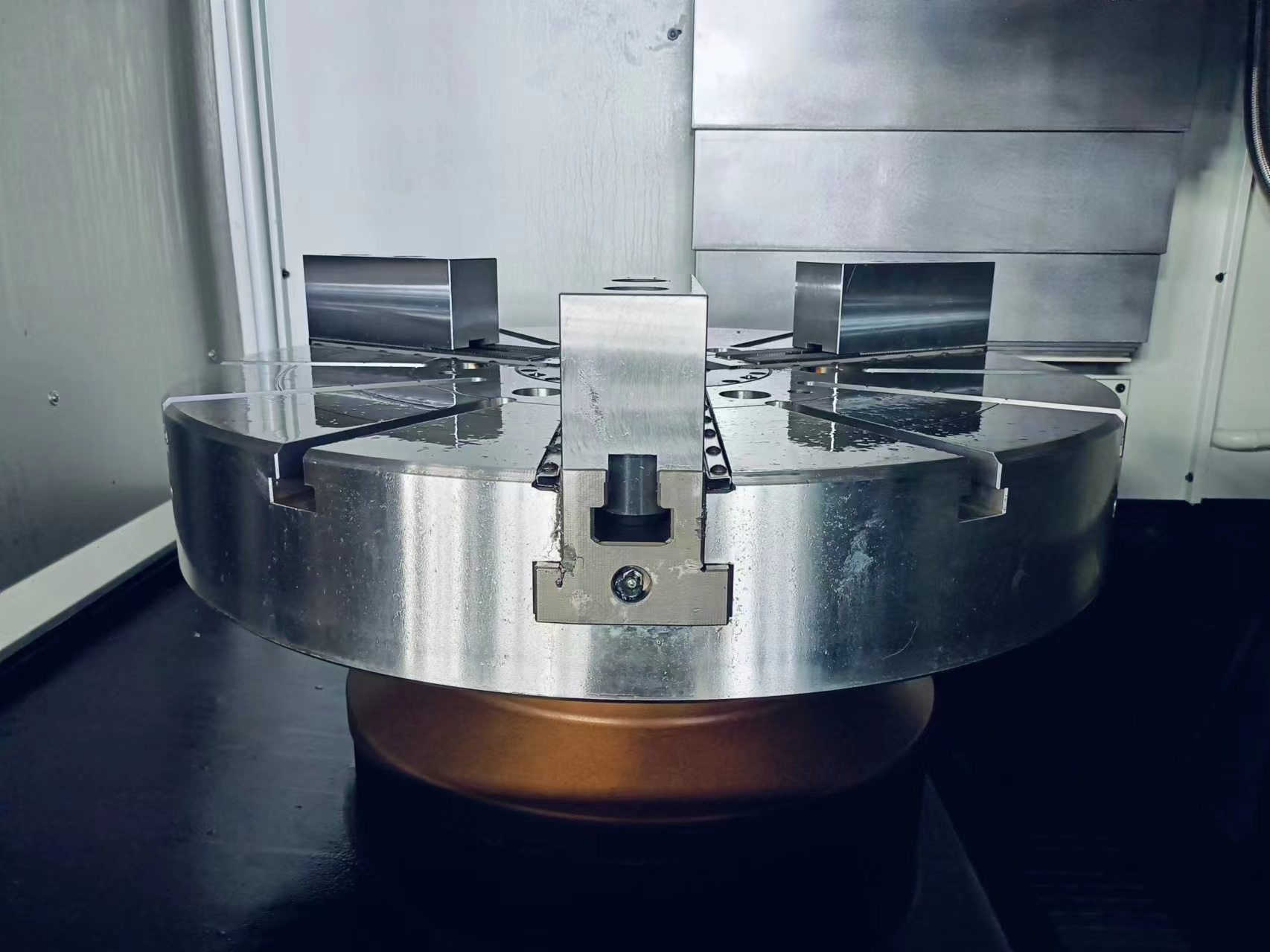

5. 15" three-jaw hydraulic chuck

6. H ydraulic rotary cylinder

7. Nitrogen balance system

8. X-axis linear rail, Z-axis linear rail

9. Hydraulic system

10. Chuck high and low voltage switching device

11. transformer

12. Electric control box heat exchanger

13. Automatic lubrication system

14. Chip conveyor (chain plate type) and chip car t

15. 10.4 " LCD color display screen

16. Chinese operation panel

17. Toolbox and tools

18. working l ight

19. Warning Light

20. Foot switch

21. Full cover sheet metal

22. Cutting fluid cooling system

23. soft claw

24. Machine tool standard colors (top: RAL 7035, bottom: RAL 9005 )

Ⅲ. Optional configurations:

1. Siemens control system

2. Oil-water separator

3. Oil mist collector

4. Hydraulic chuck 18" 21" 24"

5. hard claws

6. Electric control box air conditioning device

7. Automatic door

8. Tool measuring system

9. Workpiece measurement system

10. VDI tool holder (E+C tool turret model)

11. two-stage gearbox

12. Safety door interlock device

13. Turnkey projects

14. Specify color (top: RAL Bottom: RAL )

1. 24- hour technical support by E-mail.

2. All of our products' warranty is 1 year.

3. All your inquiries and questions will be replied in 24 hours,please feel free to contact us at any time.

Payment can be achieved by many ways including L/C,T/T,and Paypal.

Welcome to contact me