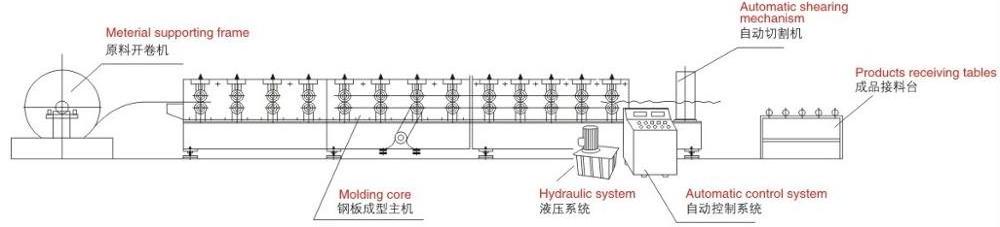

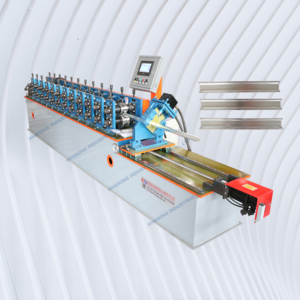

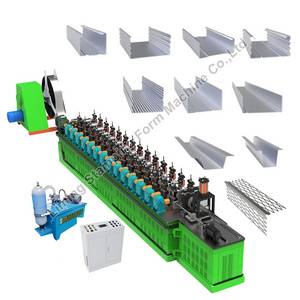

1、Each head bears 2T

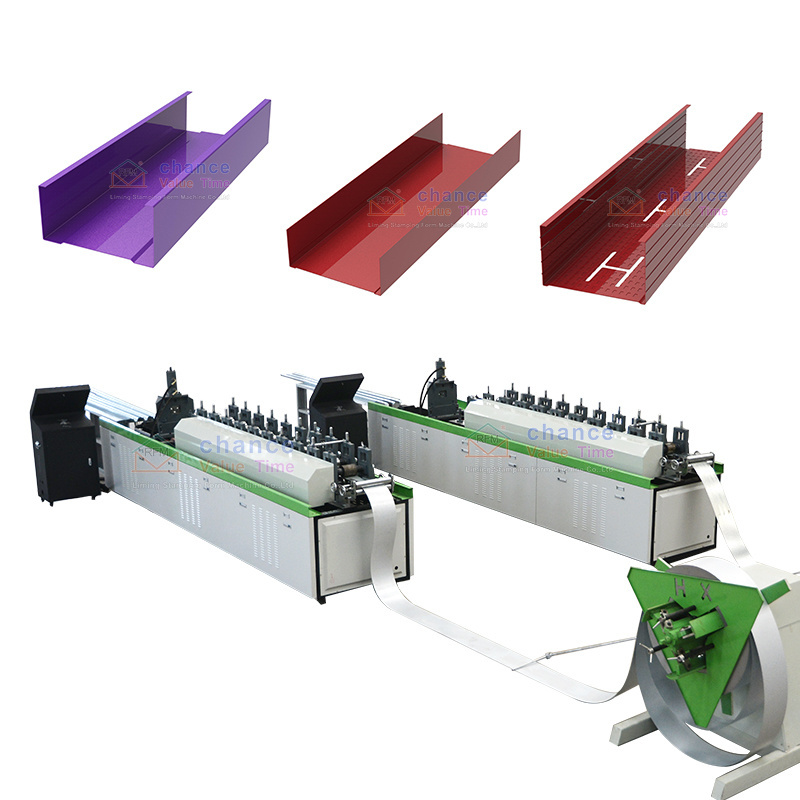

2、Loading is more convenient

3、uninterrupted production