- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4000*900*1600mm

-

Weight (KG):

-

1800 kg

-

Edge banding machine name:

-

edge banding machine kdt

-

Application:

-

Kitchen cabinet, wardrobe, office table

-

Application material:

-

woodworking plywood mdf board making

-

Material:

-

PVC, Acrylic, Veneer

-

Model:

-

Full automatic, Semi automatic

-

Standard Functions:

-

Gluing, End cutting, Fine trimming, Scraping, Buffing

-

Optional Functions:

-

Premilling,Grooving,Rough trimming

-

Feed speed:

-

12-20m/min

-

Workpiece:

-

10-60mm

-

Working methods:

-

Automatic Hot Press

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GoodCut

-

Voltage:

-

220V/380V/customized

-

Dimension(L*W*H):

-

4000*900*1600mm

-

Weight (KG):

-

1800 kg

-

Edge banding machine name:

-

edge banding machine kdt

-

Application:

-

Kitchen cabinet, wardrobe, office table

-

Application material:

-

woodworking plywood mdf board making

-

Material:

-

PVC, Acrylic, Veneer

-

Model:

-

Full automatic, Semi automatic

-

Standard Functions:

-

Gluing, End cutting, Fine trimming, Scraping, Buffing

-

Optional Functions:

-

Premilling,Grooving,Rough trimming

-

Feed speed:

-

12-20m/min

-

Workpiece:

-

10-60mm

-

Working methods:

-

Automatic Hot Press

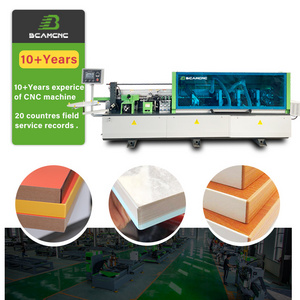

pvc production machine automatic edge banding machine for woodworking plywood mdf board making

High efficiency full automatic edge banding machine has additional functions such as corner trim and pre-milling etc., material edge banding work. This banding machine is widely used for kitchen cabinet, wardrobe, office table etc. furniture edging treatment, The edge banding material can be PVC, Acrylic, Veneer etc, It’s your idea selection for full functions automatic edge banding machine.

|

SPECIFICATIONS

|

|||

|

Model

|

Full automatic

|

||

|

Semi automatic

|

|||

|

Functions

|

Standard

|

Gluing, End cutting, Fine trimming, Scraping, Buffing.

|

|

|

Optional

|

Premilling,Grooving,Rough trimming

|

||

|

Workpiece thickness

|

10-60mm

|

Feed speed

|

12-20m/min

|

|

Workpiece width

|

≥60mm

|

Total power

|

4kw-17kw

|

|

Workpiece length

|

≥100mm

|

Air press

|

0.6-0.7Mpa

|

|

Edge width

|

10-65mm

|

Weight

|

500-2000kg

|

|

Edge thickness

|

0.4-3mm

|

Overall size

|

2500-5600*800*1600mm

|

1)The glue mechanism adopt a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

2)The buffing device adopt the board processed by cotton polishing wheel, by end- polishing to make a more smooth surface.

3)End-cutting mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the Cutting surface smoothly.

4) Scraping unit for a perfect finishing of the applied edge.

| Model | GC-EB | ||

| Functions | Gluing, End cutting, Rough trimming, Fine trimming, Corner round, Scraping, Buffing | ||

| Workpiece thickness | 10-60mm | Feed speed | 13-23m/min |

| Workpiece width | ≥60mm | Total power | 15kw |

| Workpiece length | ≥100mm | Air press | 0.6Mpa |

| Edge height | 15-65mm | Weight | 2200kg |

| Edge thickness | 0.4-3mm | Overall size | 5400 x 1000 x 1600mm |

| 1 | Gluing, Fine trimming, Buffing. |

| 2 | Gluing, Fine trimming, Scraping, Buffing. |

| 3 | Gluing, Rough trimming, Fine trimming, Scraping, Buffing. |

| 4 | Gluing, End cutting, Fine trimming, Buffing. |

| 5 | Gluing, End cutting, Fine trimming, Scraping, Buffing. |

| 6 | Gluing, End cutting, Rough trimming, Fine trimming, Scraping, Buffing. |

| 7 | Gluing, End cutting, Rough trimming, Fine trimming, Scraping, Slotting, Buffing. |

| 8 | Gluing, End cutting, Rough trimming, Fine trimming, Scraping, Buffing. |

| 9 | Gluing, End cutting, Rough trimming, Fine trimming, Corner rounding, Scraping, Buffing. |

| 10 | Premilling, Gluing, End cutting, Rough trimming, Fine trimming, Corner rounding, Scraping, Bu |

Features

1. Through special structure, the edge-sealing sheet and the edge-sealing material are evenly coated and pressed, so that the edge-sealing strip is more firmly attached.

2. Through the precision linear guide motion, the rapid cutting structure of the high-frequency high-speed motor is automatically tracked by the master to ensure that the cut surface is smooth and smooth.

3, using the model automatic tracking and high-frequency high-speed motor structure, repair the excess edge banding material on the edge of the board edge strip.

4, used to eliminate the ripples caused by the cutting process of trimming non-linear motion.

5. Clean the finished plate with a cotton polishing wheel and smooth the edge of the edge by polishing.

Smile Ji

Jinan GoodCut CNC Machinery Co.,Ltd.

Wechat/Whatsapp: 008618396857273

Email: smileji AT goodcutcnc.com

Skype: smilecnc AT hotmail.com