- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

techence standard forks

-

Name:

-

Factory direct supply class 4A forklift fork shoes with ISO

-

Type:

-

forklift forks

-

Application:

-

1-8 ton Forklift

-

Material:

-

40Cr

-

C%:

-

0.37-0.44 double forklift forks

-

Si%:

-

0.17-0.37 double

-

Tensile Strength:

-

935MPA/MM double

-

Surface Hardness:

-

255-385HB double

-

Certification:

-

ISO9001 CE

-

Color:

-

Black

Quick Details

-

Warranty:

-

6 Months

-

Weight (KG):

-

56

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

techence standard forks

-

Name:

-

Factory direct supply class 4A forklift fork shoes with ISO

-

Type:

-

forklift forks

-

Application:

-

1-8 ton Forklift

-

Material:

-

40Cr

-

C%:

-

0.37-0.44 double forklift forks

-

Si%:

-

0.17-0.37 double

-

Tensile Strength:

-

935MPA/MM double

-

Surface Hardness:

-

255-385HB double

-

Certification:

-

ISO9001 CE

-

Color:

-

Black

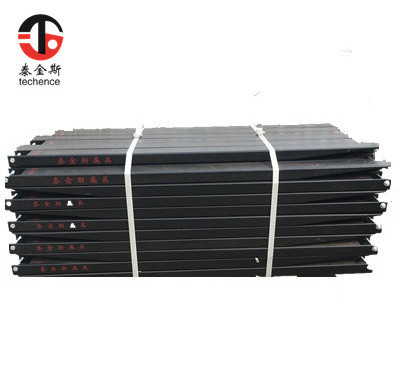

forklift fork shoes

forklift forks

Forklift Forks Specification:

Our forks’ capacity range from 0.5 ton to 80tons for class2A,class3A,class4A

|

Capacity/pair (kg) |

Size (T*W mm) |

Material |

Height (mm) |

Length (mm) |

| 1T | 2A32*100 | 40Cr | 540 | any length you want |

| 1.5T | 2A35*100 | 40Cr | 540 | |

| 2.5T | 3A45*100 | 40Cr | 655 | |

| 3T | 3A45*122 | 40Cr | 655 | |

| 3.5T-4T | 3A50*122 | 40Cr | 655 | |

| 4.5T | 3A50*150 | 40Cr | 655 | |

| 5T | 4A50*150 | 15B37 | 845 | |

| 6T | 4A60*150 | 15B37 | 845 | |

| 7T | 4A65*150 | 15B37 | 845 |

Cross Section Size: 25x76mm; 50x50mm; 32x100mm... 250x500mm, Length from 600mm to 4500mm.

( Note : these are a smaill part of the specification we could produce, not all)

Product Inspection:

Product Details:

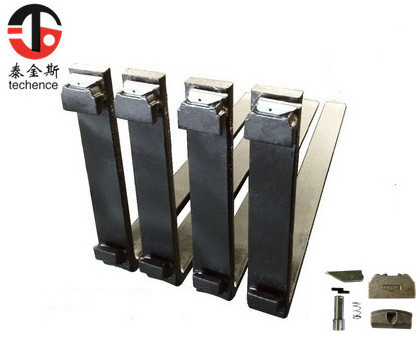

Standard Fork Mount:

General

1. Raw Material: Purchased from entrusted supplier with third party inspection.

2. Experienced technicians and workers with regular training to keep stable quality.

3. ISO 2328 and ISO2330 standard production process and fully heat-treated.

4. 3 times static overload testing

Fork bodies: 15B37,33MnCrTiB,42CrMo,40Cr,35CrMo

Hanger:20Cr

Tube:20#

Chemical Composition

| Material No. | C% | Si% | Mn% | Cr% | Mo% |

| 15B37 | 0.30~0.35 | 0.15~0.35 | 1.25~1.50 | 0.30~0.60 | |

| 33MnCrTiB | 0.30~0.35 | 0.15~0.35 | 1.25~1.50 | 0.30~0.60 | |

| 40Cr | 0.37~0.45 | 0.20~0.40 | 0.50~0.80 | 0.80~1.10 | |

| 42CrMo | 0.38~0.45 | 0.20~0.40 | 0.50~0.80 | 0.90~1.20 | 0.15~0.25 |

| 35CrMo | 0.32~0.40 | 0.20~0.40 | 0.40~0.70 | 0.80~1.10 | 0.15~0.25 |

| 20Cr | 0.17·0.24 | 0.17~0.37 | 0.50~0.80 | 0.70~1.0 | |

| 20# | 0.17~0.24 | 0.17~0.37 | 0.35~0.65 | 0.25 |

Welding: with Ar+CO 2 protection

Mechanical Properties:

| Material No. | Yield Strength(σb) | Tensile strength(σb) | Impact(-20° C-V) | Surface hardness |

| 15B37 | ≥784Mpa | ≥931Mpa | ≥27J | HB 285~363 |

| 33MnCrTiB | ≥784Mpa | ≥931Mpa | ≥27J | HB 285~363 |

| 40Cr | ≥785Mpa | ≥981Mpa | ≥27J | HB 285~363 |

| 42CrMo | ≥932Mpa | ≥1079Mpa | ≥27J | HB 285~363 |

| 35CrMo | ≥834Mpa | ≥981Mpa | ≥27J | HB 285~363 |

Crack detection must be done for every fork after shot blasting.

Producing standard: ISO 2328

Inspection standard: ISO2330/2002

Painting: Black or as requested.

Different type of forklift forks we could produce:

Blank Type forklift forks

Shaft type forklift forks

Port Forklift Forks

Packing on seaworthy steel pallets.

Plastic Wrap can be choose

2.5 ton max per pallet

Our Advantage

1. 11 years of forklift forks manufacturing experience.

2. Competitive Price.

3.100% quality inspection.

4.Thicker Heel.

5.CE Certificate.

6. All size available.

7.OEM available.

Certification

1. Laiwu Techence Forging Co., Ltd. is a professional forklift forks & attachments manufacturer.

2.Have 4 production lines, 3 section bar lines and a forging line

3.Able to produce over 300,000 pcs of high quality forks annual.

4.

Products include but not limited to Standard Forks, Shaft/ Pin type forks, Heavy Duty Forks, 20- 46MT Port Fork (Container Forklift Fork), 20-60 ton Mining Fork, Loading Fork, Farm Fork, Stone Fork (Patent), folding fork etc.. Forklift attachments we have: Rotator, side shift, fork carrier, bale clamp, fork arm extensions, etc..

5.Main Equipment: 3T & 5T electro-hydraulic hammer, 800T & 500T hydraulic press machine, straighten machine, shot blast cleaning machine, flame cutting machine, linear cutting machine etc..

Some of the Equipments:

Q: What is your delivery time?

A: Within 10 days production time for small forks, and 20 days for Heavy Duty forks.

Q: What do you mean thicker heel?

A: All the forks we produced experienced a special heel burble process, makes our forks heel is 140%-160% of forks' thickness.

Q: What is the MOQ of your company?

A: 10 pcs or $1,000.00 amount.

Q: What is the acceptable payment term?

A: T/T or L/C, purchase on Alibaba is prefered.

Q: How about your quality and quality inspection?

A: Our QA department do 100% inspection, on every process.

Q: Does OEM available?

A: Yes, OEM is OK for us.

Q: What is the HS code of your forklift forks?

A: 84312090

More KInds of Products of Forklilft Parts: