- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

6120x2300x2000

-

Power (kW):

-

55 kW

-

Weight (KG):

-

11400 KG

-

Category:

-

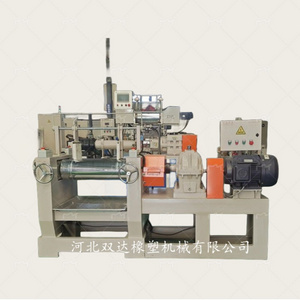

Rubber mixing mill

-

Roller:

-

chilled cast iron

-

Service:

-

OEM ODM buyer label

-

Motor:

-

Chinese famous brand

-

Reducer:

-

Hard-tooth surface gear reducer

-

Rolling bearing:

-

Dual-listed rolling bearings

-

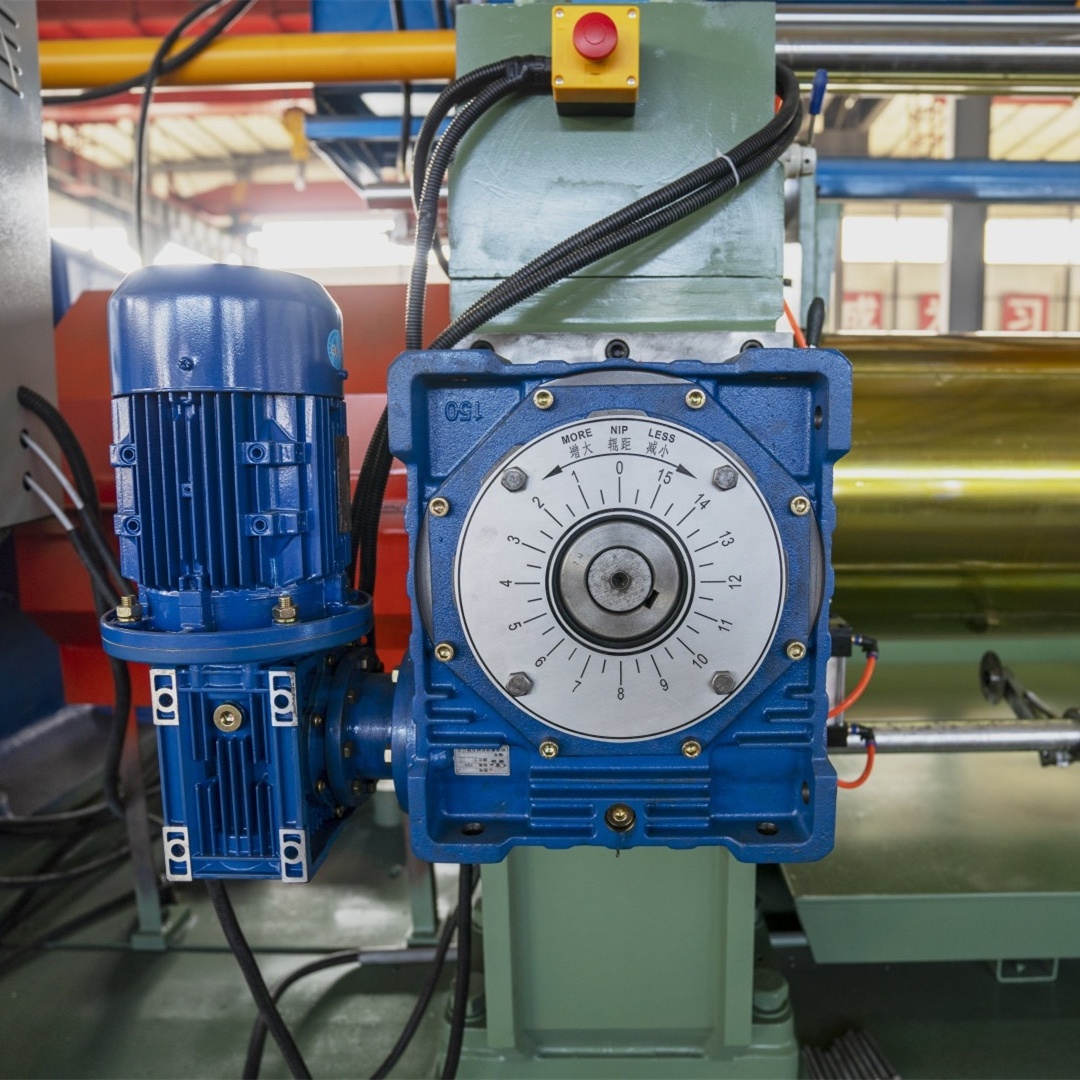

Roll gap adjustment:

-

electric automatic

-

Name:

-

open mixing mill

-

Weight:

-

11400kg

-

Power(W):

-

55KW

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HUICAI

-

Voltage:

-

380V 450V

-

Dimension(L*W*H):

-

6120x2300x2000

-

Power (kW):

-

55 kW

-

Weight (KG):

-

11400 KG

-

Category:

-

Rubber mixing mill

-

Roller:

-

chilled cast iron

-

Service:

-

OEM ODM buyer label

-

Motor:

-

Chinese famous brand

-

Reducer:

-

Hard-tooth surface gear reducer

-

Rolling bearing:

-

Dual-listed rolling bearings

-

Roll gap adjustment:

-

electric automatic

-

Name:

-

open mixing mill

-

Weight:

-

11400kg

-

Power(W):

-

55KW

The Founctions

Plastic refining, mixing, pressing and crushing of raw glue; Purification of impurities in mixing, pressing sheet and glue material; Hot refining and supplying of mixing glue;

Crush, mix and press the regenerated glue. It is widely used in plastic processing and paint and pigment industry.

The Features

1.The roll adopts the vanadium titanium metal alloy chilled cast iron and its surface is hard and wear-proof. The internal cavity is processed to make temperature well proportioned on the roll surface.

2. The machine is equipped with an overload protection device to prevent the main components from being damaged.

3. The machine is also equipped with an emergency brake device. When an emergent arises, just draw the safety pull rod, and the machine will stop immediately. It is safe and reliable.

4. The transmission system adopts a hardened tooth-surface reducer, which has a compact structure with higher transmission efficiency, lower noise and longer service life.

5. The base frame is a whole framework, which is convenient for installation.

6. Stock bender for direct rubber sheet and knife to cut as your need to assemble.

7. Auto-lubrication sysytem for greese or oil and match bearing bush.

| Type | XK-160 | XK-250 | XK-300 | XK-360 | XK-400 | XK-450 | XK-550 | XK-560 | XK-610 | |||

| 1.Roll diameter (mm) | 160 | 250 | 300 | 360 | 400 | 450 | 550 | 560-510 | 610 | |||

| 2.Roll working length (mm) | 320 | 620 | 700 | 900 | 1000 | 1200 | 1530 | 1530 | 1930 | |||

| 3.Front roll linear speed (m/min) | 9 | 16.3 | 16.3 | 16.7 | 18.65 | 21.8 | 28 | 26.4 | 30.5 | |||

| 4.Speed ratio of rolls | 1:1.35 | 1:1.7 | 1:1.25 | 1:1.25 | 1:1.27 | 1:1.27 | 1:1.2 | 1:1.2 | 1:1.1 | |||

| 5.Max roll space (mm) | 0.1-4.5 | 0.1-8 | 0.1-4.5 | 0.1-10 | 0.1-10 | 0.1-12 | 0.1-16 | 0.1-15 | 0.1-15 | |||

| 6.Compound feeding capacity (kg) | 1-2 | 10-15 | 5-15 | 15-20 | 18-35 | 50 | 50-65 | 50-65 | 140 | |||

| 7.Motor power (kw) | 5.5 | 18.5 | 30 | 30 | 45 | 55 | 110 | 90 | 160 | |||

| 8.Overal size (mm) | 1120 | 3300 | 4020 | 4200 | 4400 | 5200 | 6300 | 6120 | 6570 | |||

| 920 | 1300 | 1500 | 1780 | 1850 | 2000 | 2300 | 2300 | 2900 | ||||

| 1350 | 1200 | 1500 | 1700 | 1760 | 1830 | 1900 | 2000 | 2100 | ||||

Advantages

- The speed reducer is the hard-tooth surface gear speed reducer of Class 6 precision, which has long service life and low noise.

- Chilled alloy cast iron roll is abrasion resistant with long service life.

- Dual-listed rolling bearings, which reduces energy consumption by 30%.

- Roll gap adjustment : electric automatic

- Motor: Frequency control of motor speed

Safty

1.Electrical protection: When the equipment overloading, equipment parking.

2. roller safety device: when the device instantly over the pressure of the roller, the insurance for the safety film sit automatically paragraph crack. To protect the rollers and other major parts (XK-400 is no such device) to make the machine run more reliable and maintenance costs to a minimum.

3. machine equipped with a brake device, in case of emergency, pull the safety lever to immediately brake, thereby reducing the occurrence of the accident.