- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Friend

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

CAPACITY

-

Weight:

-

6000

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Raw material:

-

PP PE Granules

-

Capacity:

-

80-350kg/h

-

Inverter:

-

ABB Brand

-

Hauling speed:

-

1.4-15m/min

-

Product:

-

PE Pipe

-

Color:

-

Customised

-

Type:

-

Pipe Extrusion Making Machine

-

Usage:

-

Water Pipe

-

Marketing Type:

-

New Product 2020

Quick Details

-

Screw Design:

-

Single-screw

-

Screw Speed (rpm):

-

110 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Friend

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

CAPACITY

-

Weight:

-

6000

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Raw material:

-

PP PE Granules

-

Capacity:

-

80-350kg/h

-

Inverter:

-

ABB Brand

-

Hauling speed:

-

1.4-15m/min

-

Product:

-

PE Pipe

-

Color:

-

Customised

-

Type:

-

Pipe Extrusion Making Machine

-

Usage:

-

Water Pipe

-

Marketing Type:

-

New Product 2020

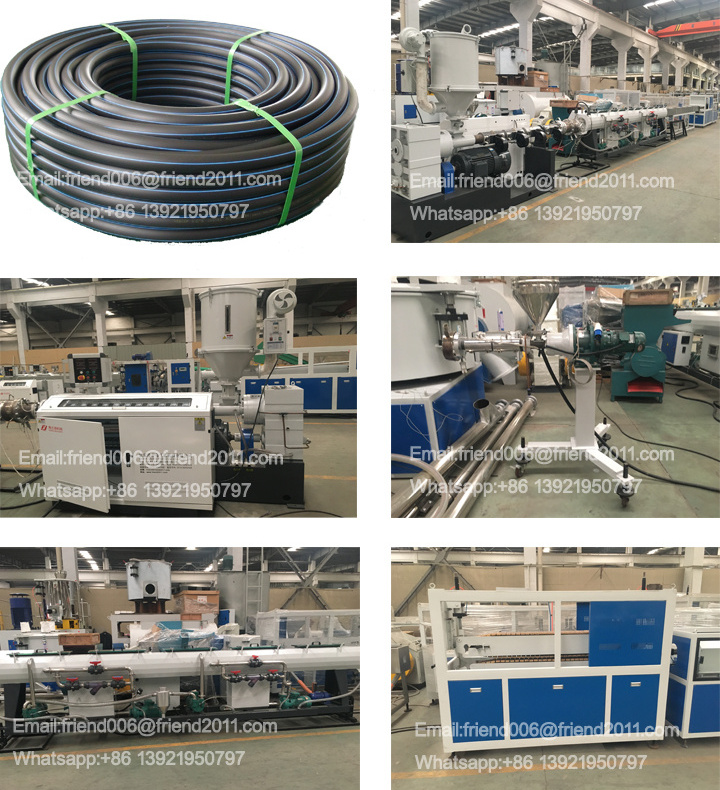

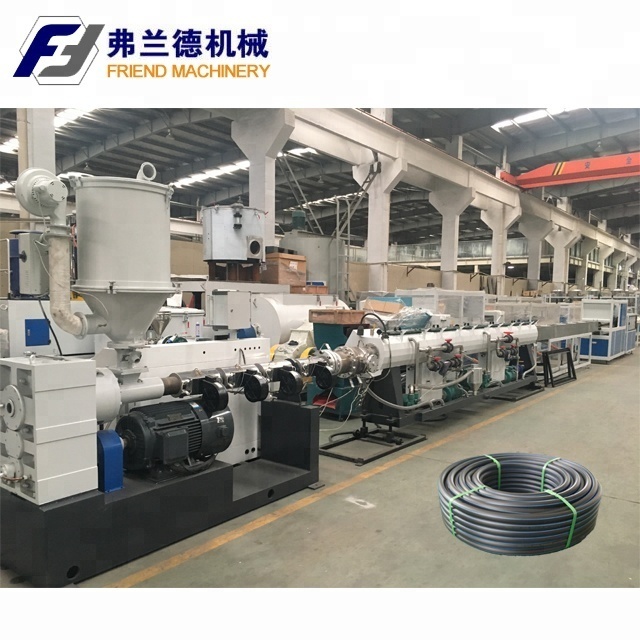

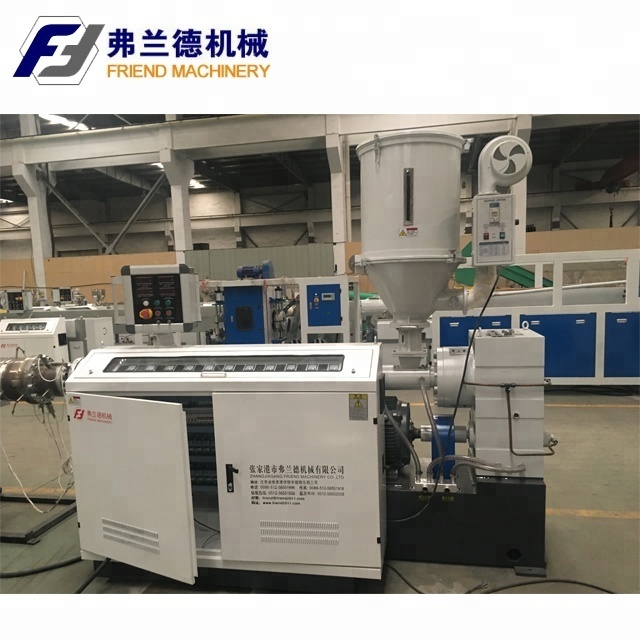

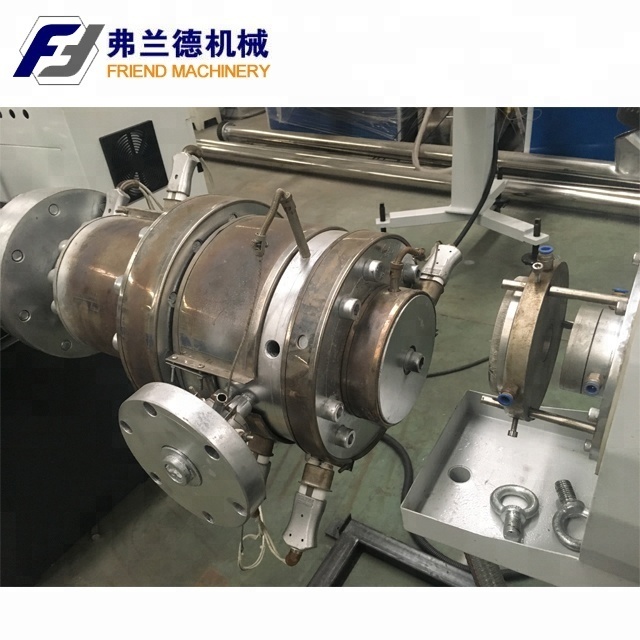

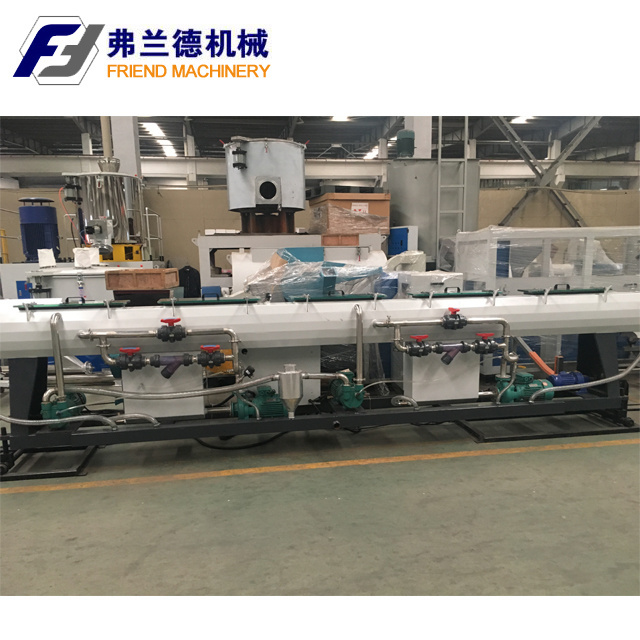

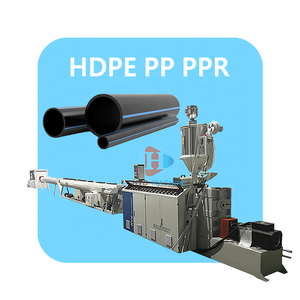

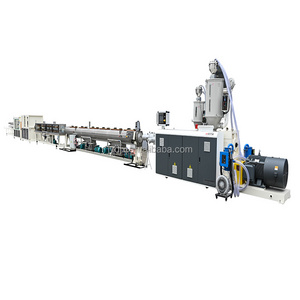

PE HDPE Water Supply Pipe and Drainage Pipe Extrusion Line / Making Machine

Description of PE HDPE pipe extrusion line:

PE series plastic pipe production line is mainly used in the production of agricultural, construction and sewage drainage, etc.The unit consists of single screw extruder, vacuum calibration tank,hauling machine, cutting machine, stacker and other components.Single-screw extruder and hauling machine adopts imported AC frequency control devices, vacuum pump and traction motors are made of high-quality products.You can choose no dust cutting, saw cutting or planetary cutting machine reliable performance, high production efficiency.

Our company can according to users’ requirements,equipped with special devices and produce inner wall spiral pipe, inner wall hollow pipe, and core layer foam pipe. This PE pipe production line also can produce other pipe materials PP, PE, PPR, HDPE and so on. Planetary cutting machine is fully automatic computer digital control, easy to operate, reliable performance, etc., reached the international advanced level.

We use low-temperature low-pressure extrusion system efficiency, improve products and plasticizing effect extrusion capacity, yield an increase of 10-15%.

Technical Parameters:

| Modle |

Pipe Diameter (mm) |

Extruder |

Output (kg/h) |

Installation Power (kw) |

Extruder Power (kw) |

| SJ45 | 16~32 | SJ45/30 SJ25/25 | 30~60 | 40 | 22 |

| SJ65 | 20~75 | SJ65/33 SJ25/25 | 80~120 | 65 | 37 |

| SJ75 | 50~160 | SJ75/33 SJ25/25 | 80~150 | 150 | 75 |

| SJ90 | 75~250 | SJ90/33 SJ25/25 | 280~350 | 200 | 110 |

| SJ120 | 160~315 | SJ120/33 SJ30/25 | 300~450 | 280 | 185 |

| SJ150 | 315~630 | SJ150/33 SJ30/25 | 550~800 | 420 | 285 |

Pictures: