Servo piston filling structure is adopted to ensure accurate filling, and heat recovery function is adopted to improve product quality after filling

- Product Details

- {{item.text}}

Quick Details

-

Applicable Industries:

-

Other

-

Weight (KG):

-

650

-

Function:

-

Homogenzing

-

Application:

-

Chemical

-

Product name:

-

Lipstick Release Machine

-

Usage:

-

Mixing Paste Proucts

-

Appliance:

-

Cream Gel Lotion Sauce

-

Machine size:

-

1600*1300*1800mm

-

Volume:

-

Costomized

-

Production Capacity:

-

3-10mold/min

-

Capacity:

-

Hour

-

Feature:

-

Work Efficiently

Quick Details

-

Brand Name:

-

powerrig

-

Type:

-

lip stick filling machine

-

Marketing Type:

-

Hot Product

-

Applicable Industries:

-

Other

-

Weight (KG):

-

650

-

Function:

-

Homogenzing

-

Application:

-

Chemical

-

Product name:

-

Lipstick Release Machine

-

Usage:

-

Mixing Paste Proucts

-

Appliance:

-

Cream Gel Lotion Sauce

-

Machine size:

-

1600*1300*1800mm

-

Volume:

-

Costomized

-

Production Capacity:

-

3-10mold/min

-

Capacity:

-

Hour

-

Feature:

-

Work Efficiently

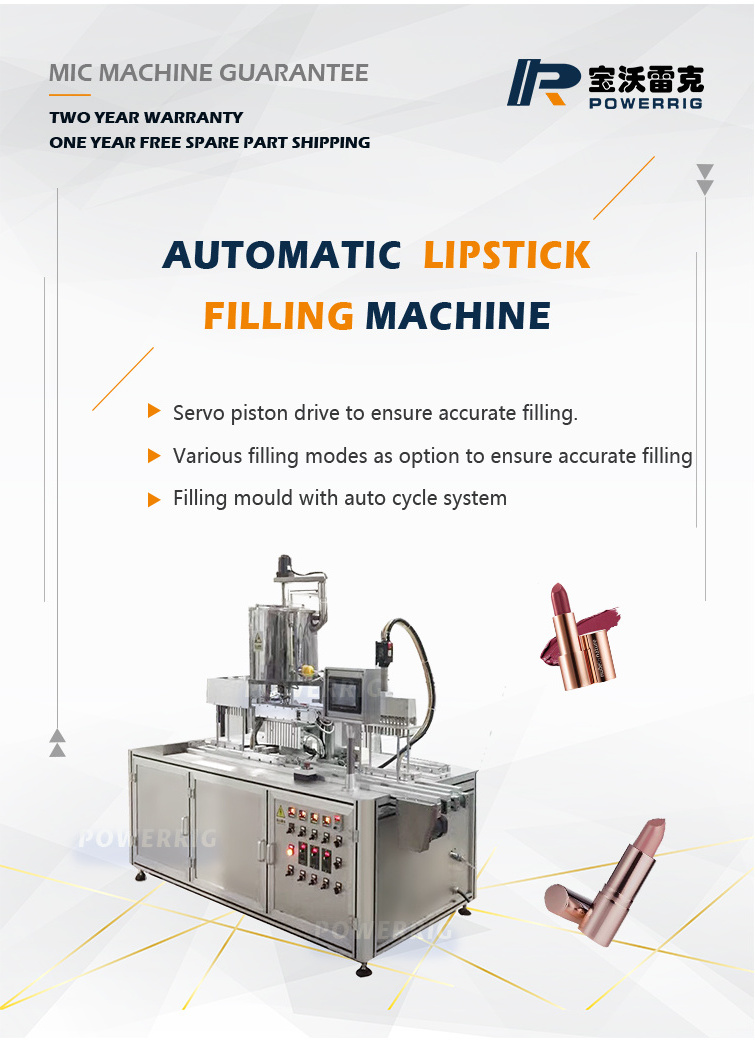

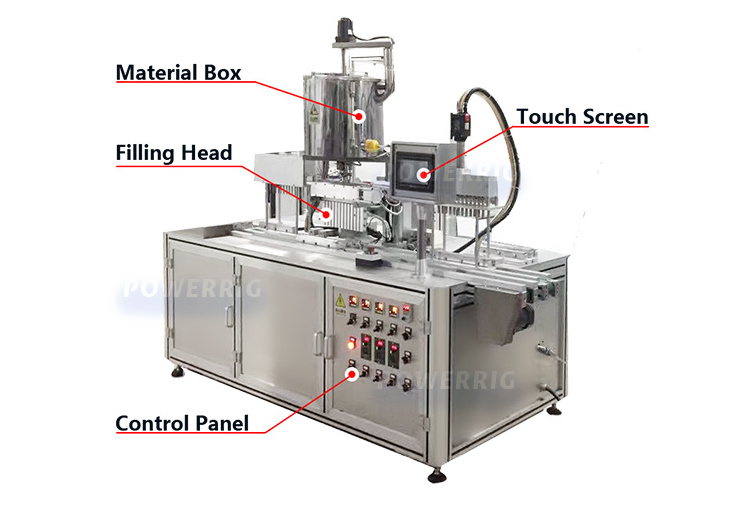

Product Introduction

this machine is full autonatie silicone mould lipstick filling machine designed for the produetion of hot filling nould products such as high qualitg lipstick. Hip balm, cosnetic pencil ete.

mainly features:

1. Servo piston prping to esure accurate rilling.

2. Maltiple flling model as option to puarantee best filling effect.

3.After filling using regenerative function to improve the quality of products

4.Filling mould with auto cycle system

|

Weight

|

650Kg

|

|

Voltage

|

220V/50Hz

|

|

Filling Quantity

|

2-10g

|

|

Air Input

|

6-8kg/cm2

|

|

Dimension

|

3100*1200*1900mm

|

|

Power Consumption

|

5Kw

|

|

Capacity

|

3000pcs/h

|

|

Additional Function

|

Air pressured tank Diving filling function

|

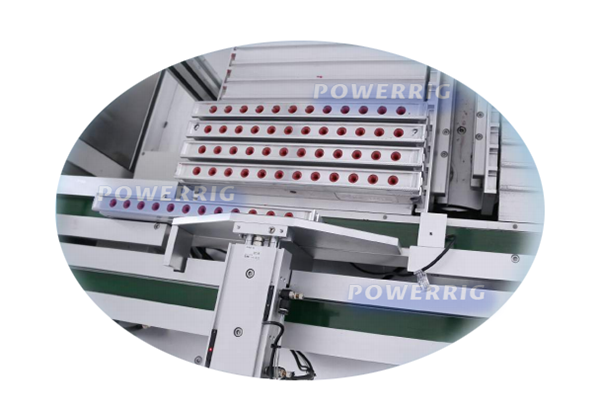

Filling Head

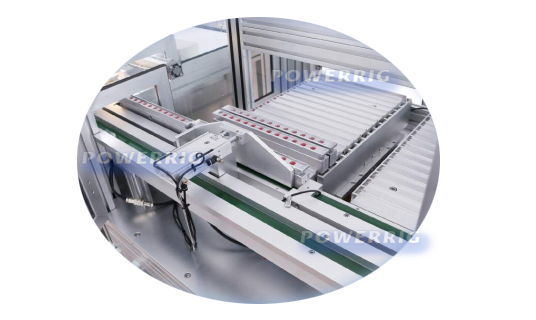

Conveyor Track

Adopt the unique mold conveying mechanism, so that the mold into the machine, keep the same freezing time, to achieve a unified standard

Freezing Room

Advanced freezing technology is adopted to make lipstick quick forming, greatly reducing the power consumption of the machine,energy saving and environmental protection

Stripper Machine

Man-machine interface control, convenient adjustment of parameters, automatic man-machine interface control, convenient adjustment of parameters, automatic grasp of the cover of the silicone mold. Demoulding process adopts servo motor control lifting, to ensure accurate demoulding

Related Product

Hot Searches