Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

hardening,heating,anealing,tempering,brazing,melting,etc

-

Worker power:

-

Three phase 380V/50~60Hz

-

Working voltage range (AC):

-

342V~430V

-

Max input current:

-

8~70A

-

Max output power:

-

100~250Khz

-

Continuous load rate:

-

100%

-

Cooling water pressure:

-

0.3Mpa/>8L/min

-

Weight(Host):

-

30kg

-

Weight(Transformer):

-

24kg

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Lipai

-

Weight (KG):

-

30

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

hardening,heating,anealing,tempering,brazing,melting,etc

-

Worker power:

-

Three phase 380V/50~60Hz

-

Working voltage range (AC):

-

342V~430V

-

Max input current:

-

8~70A

-

Max output power:

-

100~250Khz

-

Continuous load rate:

-

100%

-

Cooling water pressure:

-

0.3Mpa/>8L/min

-

Weight(Host):

-

30kg

-

Weight(Transformer):

-

24kg

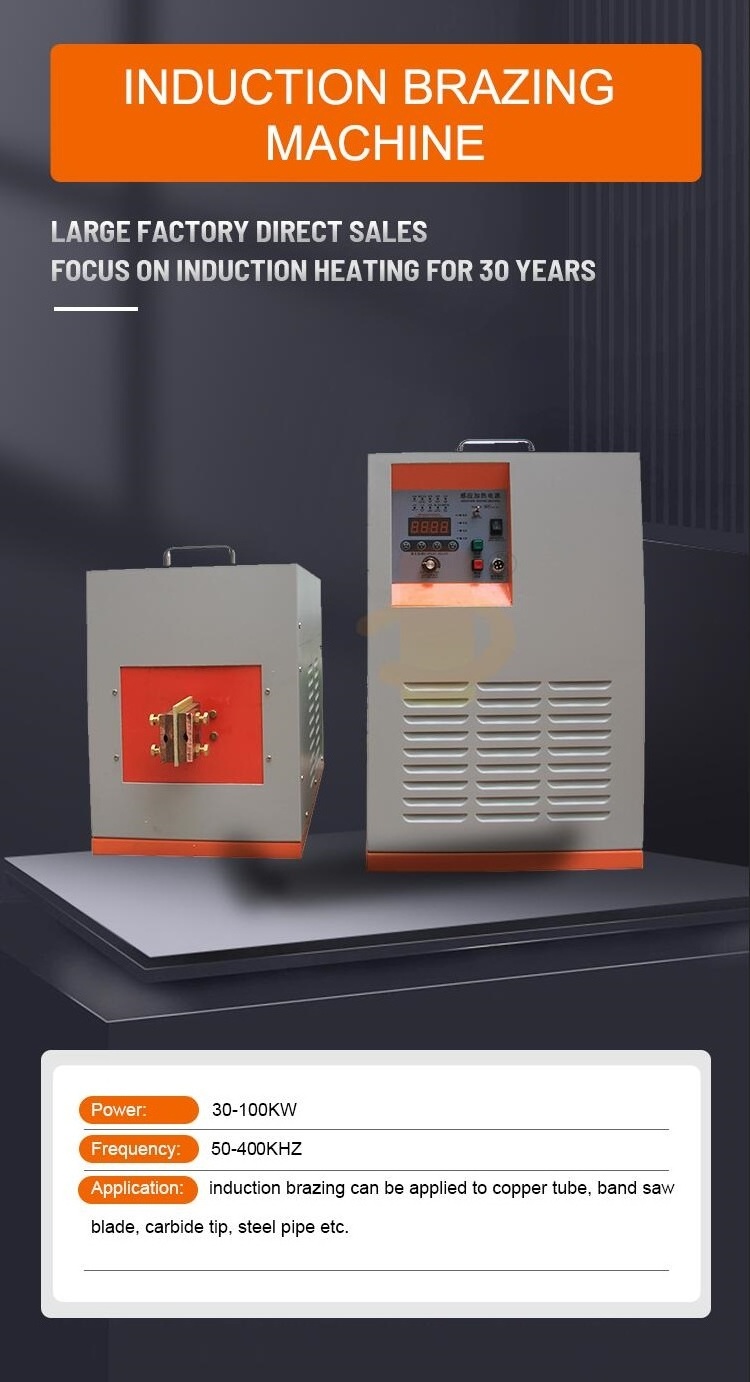

It is mainly through heating to a certain temperature to melt the solder, which, make the two kinds of metal material or different materials together, specific applications are as follows:

1. The welding of metal cutting tools: diamond tools, grinding, drilling, alloy saw blade, carbide turning tool, milling cutter, reamer, planer, drill bits and other woodworking welding.

2. The welding of metal mechanical parts: hardware bathroom products, refrigeration, copper fittings, lighting accessories, precision mold parts, metal handle, mixer, alloy steel and steel, steel and copper, copper and copper equivalent or dissimilar metals metal silver soldering, brazing.

3. Composite solder pot is mainly used for round, square and other shaped surface stainless steel pot with three-layer aluminum brazing can also be used for other flat metal brazing.

4. An electric kettle (electric coffee pot) of hot plate welding is mainly used for stainless steel flat-bottomed, aluminum heating pipe with a variety of shapes between the brazing.

1. Fast welding speed

2. High cost performance

3. Stable performance

4. Safe and reliable

5. Flexible and convenient

1. Metal tube welding:

such as copper tube, steel tube, and aluminum tube’s butt welding, plug welding and

welding sets.

2. Alloy cutter welding:

such as alloy turning, milling cutter, planer, saw blades, reamer, boring knife.

3. Carbide saw blade welding:

such as diamond saw blade welding, marble saw blade welding, woodworking saw blade welding,?cut grass piece of welding, cut aluminum welding,

4. Metal welding:

such as towel rack, soap nets, towel holder, auto-accessories, motorcycle accessories, metal terminals, hardware pieces, electric heating tube parts and fasteners.

|

Model Technical Parameter

|

GS-30

|

GS-40

|

|

Working Power

|

Three phase 380v/50-60hz

|

Three phase 380v/50-60hz

|

|

Working Voltage

|

342-430v

|

342-430v

|

|

Maximum Output Power(KW)

|

30

|

40

|

|

Max Input Current(A)

|

8-70

|

10-90

|

|

Oscillation Frequency(KHZ)

|

100-250

|

100-250

|

|

Cooling Water Pressure(Mpa)

|

0.3

|

0.5

|

|

Cooling Water Flow(L/min)

|

8

|

10

|

|

Generator Size(mm)

|

650*250*540

|

850*430*900

|

|

Transformer Size(mm)

|

500*270*450

|

870*420*490

|

|

Generator Weight(kg)

|

40

|

50

|

|

Transformer Weight(kg)

|

32

|

30

|

1.What is your minimum order quantity?

Currently we do not have a strict policy on this, so any order is welcome.

2. Are you a manufacturer or a trading company?

Yes, you can rest assured that we are a manufacturer with extensive experience in doing business at home and abroad.

3. We are not good at the operation and installation of your machine

Our machine is easy to operate, does not require professional training, and will send you instruction manuals and videos. In addition, we have professional engineers who can solve all problems.

4. How about the packaging? ......What should I do if the machine is damaged?

Usually the machine is packed in wooden boxes, standard export cartons, plywood cartons, and can also be packed according to your requirements. In the event of damage, we will arrange a replacement.

5. We have never cooperated before, how can i trust your company and machine?

We have more than 20 years experience in induction heating field. We have our own factory and technical team and have no complaints about Alibaba and our machines. We have nearly 15 years of export experience. Our machines have been exported to more than 60 countries and have good feedback. If necessary, we can provide the company name and website for your reference.Welcome to visit our factory at any time!

Hot Searches