- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

tianyuan

-

Voltage:

-

customised

-

Power:

-

200kw

-

Dimension(L*W*H):

-

43m*2.3m*2.3m

-

Weight:

-

50 kg

-

Name:

-

ERW hollow GI/galvanized steel pipe tube roll forming machine

-

Raw material:

-

carbon steel black steel,mild steel,stainless steel

-

Pipe shape:

-

Rectangle,round,square,hollow,oval

-

Pipe diameter:

-

20~63mm

-

Pipe thickness:

-

0.8~3.0mm

-

Welding type:

-

HF ERW

-

Pipe application:

-

Construction Tubes,ladder&Scaffoldings pipe,furniture pipe

-

Total power of Line:

-

450kw

-

Cutting system:

-

Fly Saw Track Cutting

-

After-sell service:

-

Service Machinery Overseas

Quick Details

-

Pipe Material:

-

GI/galvanized steel

-

Production Capacity:

-

0~80m/min

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

tianyuan

-

Voltage:

-

customised

-

Power:

-

200kw

-

Dimension(L*W*H):

-

43m*2.3m*2.3m

-

Weight:

-

50 kg

-

Name:

-

ERW hollow GI/galvanized steel pipe tube roll forming machine

-

Raw material:

-

carbon steel black steel,mild steel,stainless steel

-

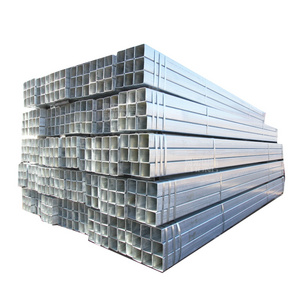

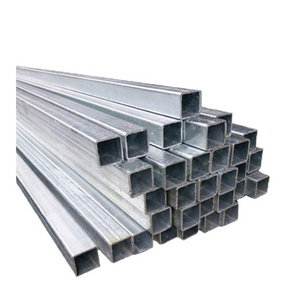

Pipe shape:

-

Rectangle,round,square,hollow,oval

-

Pipe diameter:

-

20~63mm

-

Pipe thickness:

-

0.8~3.0mm

-

Welding type:

-

HF ERW

-

Pipe application:

-

Construction Tubes,ladder&Scaffoldings pipe,furniture pipe

-

Total power of Line:

-

450kw

-

Cutting system:

-

Fly Saw Track Cutting

-

After-sell service:

-

Service Machinery Overseas

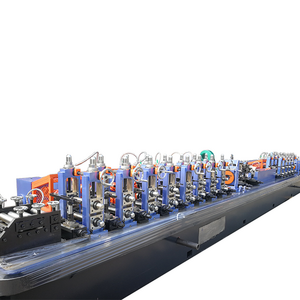

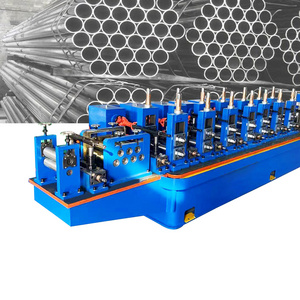

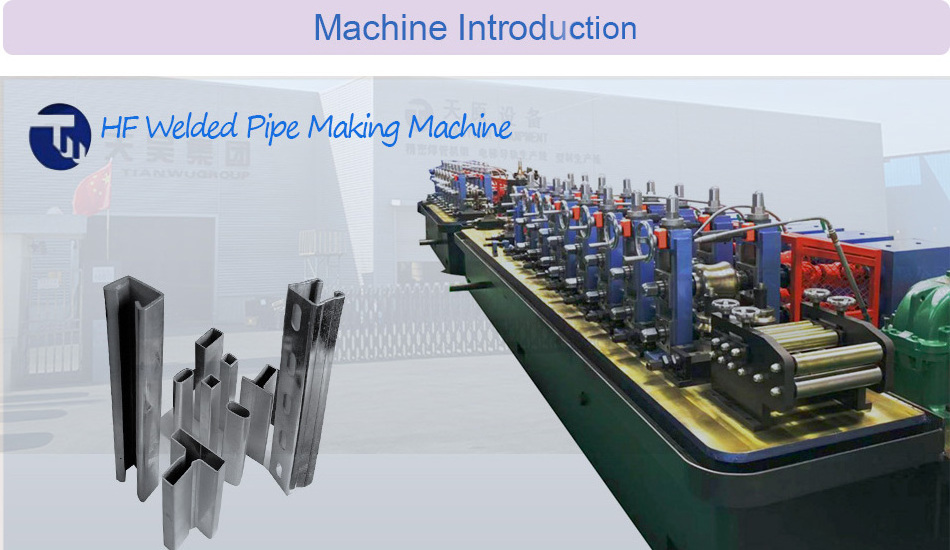

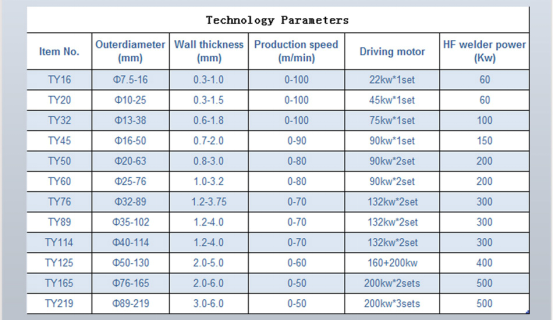

ERW hollow GI/galvanized steel pipe tube roll forming machine is specialized equipment to produce high frequency straight seam welded pipes for structural pipe and industrial pipe with Φ20mm~Φ63mm and wall thickness of 0.8~3.0mm. These ranges can be adjusted according to customers’ need .Through optimization design, best materials choice, and accurately fabrication and rolls, the whole line can be reached high precision and high speed.

ERW hollow GI/galvanized steel pipe tube roll forming machine can produce welded tubes of different specifications (pipe diameter, thickness, and length) according to the adjustment and configuration of the machine. We divide these units into 12 different models. These models can be modified according to the needs of customers .The following is our products configuration table and different models of the unit parameter table. Welcome to contact us for more details.

|

Configuration |

|

|

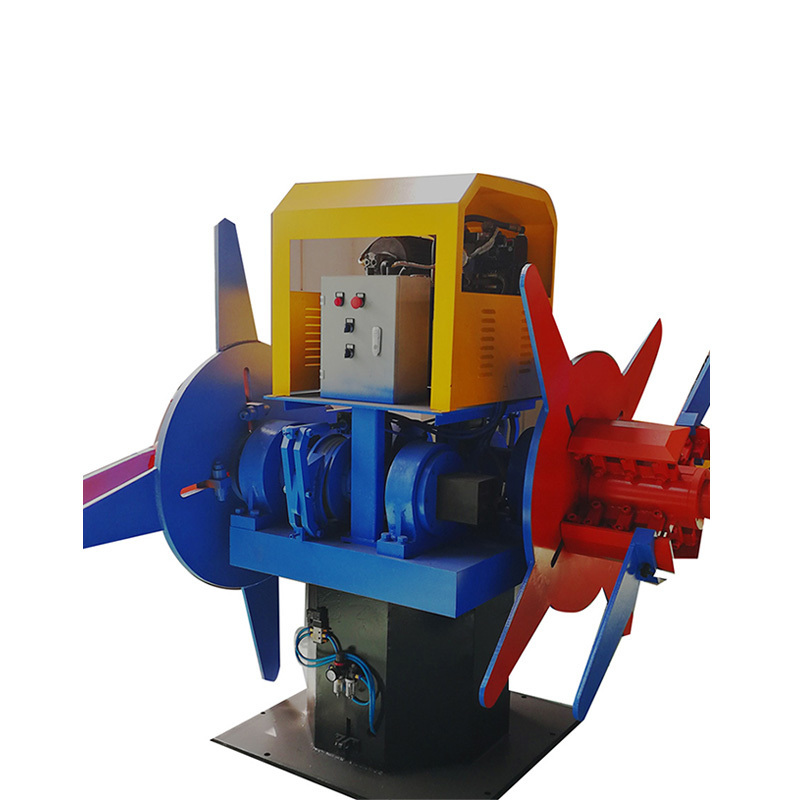

Decoiler |

Double/Single-head/Manual/Pneumatic/Hydraulic |

|

Shear&butt welding |

Manual welding/Automatic welding |

|

Accumulator |

Vertical/Horizontal accumulator |

|

Forming and Sizing unit |

DC motor/AC motor |

|

Solid HF welder |

Traditional solid/Integrated welder |

|

Computer flying saw |

Hot saw/Cold saw |

|

Run-out table |

Passively/Pneumatic turnover |

Technology Process: Uncoiling→ shearing →Accumulating→ Leveling→ Forming→ HF welding→ Deburring→ Cooling→ Sizing→ Straightening→ Cutting→ Discharging