- Product Details

- {{item.text}}

Quick Details

-

Power:

-

5.5-55kw

-

Dimension(L*W*H):

-

1200*550*750mm

-

Weight (KG):

-

1000

-

Name:

-

Wood Timber Crushing Machine, Sawdust Wood Hammer Mill For Sale

-

Raw material:

-

Wood Pieces

-

Keywords:

-

Wood crusher

-

Final product:

-

Sawdust Fine Powder

-

Suitable for:

-

Waste Wood Recycling

-

COLOR:

-

Customer Required

-

Motor:

-

Diesel Motor Electric Motor

-

Feature:

-

High Efficiency Low Cost

-

Packing:

-

Standard Wood Package

-

After-sales Service Provided:

-

Service Machinery Overseas

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Mascot

-

Voltage:

-

CUSTOMIZED

-

Power:

-

5.5-55kw

-

Dimension(L*W*H):

-

1200*550*750mm

-

Weight (KG):

-

1000

-

Name:

-

Wood Timber Crushing Machine, Sawdust Wood Hammer Mill For Sale

-

Raw material:

-

Wood Pieces

-

Keywords:

-

Wood crusher

-

Final product:

-

Sawdust Fine Powder

-

Suitable for:

-

Waste Wood Recycling

-

COLOR:

-

Customer Required

-

Motor:

-

Diesel Motor Electric Motor

-

Feature:

-

High Efficiency Low Cost

-

Packing:

-

Standard Wood Package

-

After-sales Service Provided:

-

Service Machinery Overseas

Diesel wood sawdust processor machine,crusher machine sawdust wood crusher machine,sawdust briquette sawdust making machine

Zhengzhou Mascot Environmental Technology Co., Ltd mainly produces wood shredder equipment, branch shredder equipment, wood sawdust shredder equipment, wood slicer equipment, and large wood shredder equipment.

The waste wood is crushed by a wood shredder, and these crushed materials can be reused, such as papermaking, power generation, bedding, feed, fertilizer, organic mulch, sawdust board, particle board, fiberboard, medium fiber Boards, Buddha incense, mosquito coils, insulating materials, edible fungi, furniture, tables, chairs, etc. These wooden products can be produced by using wood shredders instead of logs, which is not only environmentally friendly but also saves on disposal The expenses generated by waste wood not only save time and effort, but also bring corresponding economic income to the users of wood shredders, and using these materials to replace logs for production is also more conducive to protecting the surrounding environment.

Raw material : Wood, scrap, branches, bark, leaves, roots, branches, peanut shells, corncob, corn stalks, straw, wheat straw, and other biomass materials.

Output: Sawdust or chips. According to the different sizes of screen mesh, the machine can cut and grind different effects.

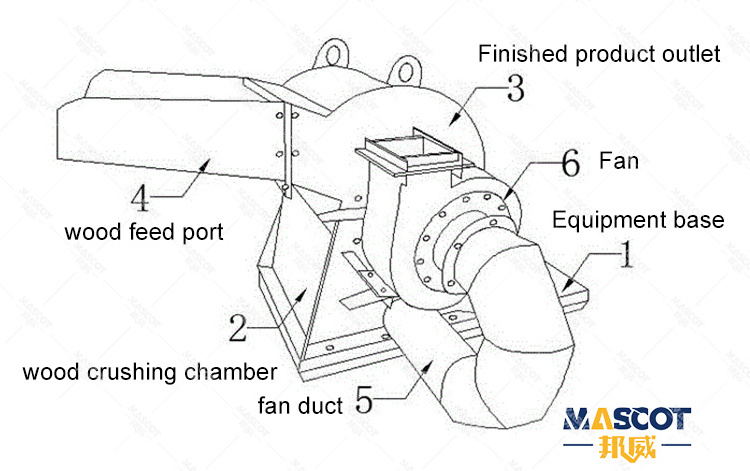

The particle size of the sawdust after being cut by the sawdust crusher is small, and it can be sent to the crushing device for further crushing without drying. The finished sawdust is sent to the collection place by the fan. Wood flour machine is a powder-making equipment used for special and difficult crushing of light, fibrous, brittle, and tough materials. The whole set of equipment is driven by only one motor, with a simple structure, compact layout, low price, stable work, low energy consumption, high output, good quality finished wood flour machine, and low processing cost. It can also make flour from wood bran, bamboo powder, chestnut skin powder, elmwood powder, wood pellets, sawdust, leather pellets, and stalk-like materials.

We are a factory, have large stock and can deliver at any time.

Product Features

1. To ensure security, the feed inlet of this machine adopts a self-suction design to avoid serious damage to operators.

2. Low investment and energy consumption,

3. High output

4. High-quality finished products

5. Easy to operate and maintain

Technical Parameters

|

Model

|

400 | 500 | 600 | 700 | 800 | 900 | 1000 |

|

Cutter diameter(mm)

|

400 |

500 | 600 | 700 | 800 | 900 | 1000 |

|

Number of blades

|

4 | 4 | 4 | 6 | 6 | 4-6 | 4-6 |

|

Blade length

|

100 | 130 | 150 | 200 | 230 | 260 | 300 |

|

Material port diameter

|

150x150 | 200x200 | 250x250 | 300x300 | 350x350 | 400x400 | 450x450 |

|

Spindle speed(r/min)

|

2600 | 2600 | 2500 | 2600 | 2300 | 2000 | 2000 |

|

Motor(kw)

|

5.5-7.5 | 11 | 15 | 18.5-22 | 37 | 45 | 55 |

|

Diesel power

|

15 | 20 | 30 | 45 | 50 | 55 | 75 |

|

CapacityIkg/h)

|

800-1000 | 1000-2000 | 2000-3000 | 3000-3500 | 3500-4000 | 4000-5000 | 5000-6000 |

Large-scale wood chipping machines can efficiently complete various medium crushing, fine crushing, and ultra-fine crushing operations from various waste wood to trees, from wood production to various hard material crushing.

Features and technical advantages of wood shredder

Less consumption of wearing parts, low operating cost, reasonable structure, advanced crushing principle and technical parameters, reliable operation, and low operating cost; all parts of the pulverizer have wear protection, which reduces maintenance costs to a minimum, and the general service life can be extended. Increased by more than 30%. The alloy cutter is wear-resistant and sharp, reliable and advanced, and has a long service life. The unique crushing system design greatly improves the service life of the equipment. The crushing chamber adopts a multi-stage crushing process and fine crushing principle device. It is characterized by a large working impact, high production efficiency, and strong crushing ability.

Zhengzhou Mascot Environmental Technology Co., Ltd is a company that integrates science, industry, and trade. The company mainly sells mechanical equipment and accessories, briquette-making machines, shredder machines, granulating machines, and mineral processing equipment. Our company follows a human-oriented mentality, honest, pioneering entrepreneurial spirit with scientific and technological innovation. We always regard technology as the motive force, and the market as the orientation to make the products at the first-class level. In product sales, we pursue the refined service and keep improving from pre-sales consulting, and on-purchase service to after-sales service.

Mascot's comprehensive service system covers technical support, after-sales service support, and spare part support, which is one of the important reasons why we are appreciated by customers. Mascot always strives to provide customers with the most valuable purchasing experience.

FAQ

1. Are you a manufacturing or trading company?

We are a factory, established in 2010.

2. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

3. What is your payment method?

30% deposit in T/T advance, 70% balance before shipment.

4. How long is the warranty? Does your company supply the spare parts?

One year. Spare parts for you at the lowest cost.

5. If I need the complete crushing plant can you help us to build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already built many mining projects in China & Overseas.