1) The motor for the host machine is Germany SIEMENS brand or ABB brand

2) Control PLC: we select original Japan Mitsubishi PLCcombine with independently develop machine control program, assure stable and high efficiency working status

3) The switch will use France Schneider brand and Japan Omron

4) Mould: newest heat treatment device and carburizing treatment will assure longer mould life span and ensure the strength of mould reach to 54-58 HRC so that the mould can be used more than 100 thousand times.

5)Material and welding: all materials and spare parts selected according to international CE standard, Carbon dioxide protection welding will assure whole line stable running.

- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Donyue

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

3800x2300x3550mm

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

11500 kg

-

Color:

-

operational

-

weight of host machine:

-

11.5 ton

-

Motor brand:

-

SIEMENS/ ABB

-

PLC:

-

German or Japan

-

Switch:

-

Omlon or Schneider

-

Pallet size:

-

1300x900x30mm

-

Molding cycle:

-

15-20S

-

Power:

-

51.2kw

-

Vibrating Force:

-

90-110KN

-

Product Name:

-

interlock block cement block Brick Making Machine in Ghana

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

-

Brick Raw Material:

-

CONCRETE

-

Production Capacity (Pieces/8 hours):

-

4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours, Other

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Donyue

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

3800x2300x3550mm

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

11500 kg

-

Color:

-

operational

-

weight of host machine:

-

11.5 ton

-

Motor brand:

-

SIEMENS/ ABB

-

PLC:

-

German or Japan

-

Switch:

-

Omlon or Schneider

-

Pallet size:

-

1300x900x30mm

-

Molding cycle:

-

15-20S

-

Power:

-

51.2kw

-

Vibrating Force:

-

90-110KN

-

Product Name:

-

interlock block cement block Brick Making Machine in Ghana

Product Overview

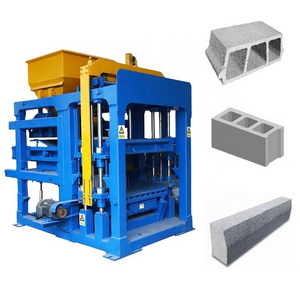

QT10-15 FULLY AUTOMATIC BLOCK MAKING PRODUCTION LINE

-- The QT10-15 block machine will convert the excess oil liquid in the pressurized time to the vibration force, and the computer will control the directional vibration, frequency conversion, braking and cancle vibration energy consumption.

-- Block molding machine low-frequency charging, high frequency vibration, mould and table vibration make concrete fully liquefied in 2 to 3 seconds, exhaust, so as to achieve high density, high strength, especially suitable for production of high-strength blocks,can be stacked after forming.

-- QT10-15 block molding machine is made from the photoelectric control host, which can be sent out of the material in time and avoid the influence of the remaining vibration, and some of the concrete is liquefied in advance.

-- The feeding hopper is equipped with oscillating feeding device, and the material is fed into the mould box by adjusting the swing fork. Imported electrical appliances, hydraulic components make the control, hydraulic two systems basically do not fault operation;

-- Block molding machine low-frequency charging, high frequency vibration, mould and table vibration make concrete fully liquefied in 2 to 3 seconds, exhaust, so as to achieve high density, high strength, especially suitable for production of high-strength blocks,can be stacked after forming.

-- QT10-15 block molding machine is made from the photoelectric control host, which can be sent out of the material in time and avoid the influence of the remaining vibration, and some of the concrete is liquefied in advance.

-- The feeding hopper is equipped with oscillating feeding device, and the material is fed into the mould box by adjusting the swing fork. Imported electrical appliances, hydraulic components make the control, hydraulic two systems basically do not fault operation;

QT10-15 Block Machine Complete Line At Site

We provide complete technical support, including site planning, installation guidance, technical training and after-sales service.

Specifications & Advantages

Electrical component brands

We use high-quality electrical components to ensure stable and efficient operation of the machine

|

MAIN SPECIFICATIONS

|

|

|

|

|||

|

Dimension of host machine

|

3800x2300x3550 mm

|

Host machine power

|

51.2kw

|

|||

|

Weight of host machine

|

11.5T

|

Vibration force

|

90-110KN

|

|||

|

Water consumption

|

10-15Ton/day

|

Pallet size

|

1300×900×30mm

|

|||

|

workshop area

|

300m²

|

Voltage

|

380/415/440

|

|||

|

Mixer model

|

JS750

|

Molding area

|

1250×840mm

|

|||

|

THEORETICAL PRODUCTION CAPACITY

|

|

|

|

|||

|

Block/ Size(LxWxH)

|

Pcs/ Mould

|

Psc/ Hour

|

Pcs/ 8 Hours

|

|||

|

Hollow Block

400x200x200mm

|

10

|

1800-2400

|

14400-16800

|

|||

|

Solid Brick

240x115x53mm

|

54

|

11435-16200

|

91480-129600

|

|||

|

I Shape Paver

200x163x60mm

|

24

|

4320

|

34560

|

|||

|

Normal paver

200x110x60mm

|

35

|

6300

|

50400

|

|||

ADVANTAGES OF QT10-15 BLOCK MACHINE

Finished Blocks

Packing & Delivery

Well Loading

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Our Services

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory

* Sample testing support.

* View our Factory

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

* Engineers available to service machinery overseas.

Customers Voice

Our Company

Dongyue Machinery Group

Dongyue Machinery Group was built in 1994,and now Dongyue is a national large-scale designated building materials machinery manufacturer, a coalition of researching, producing and marketing, and services with registered asset of 234 million RMB, total asset of 1 billion RMB, total area of 1,332,000square meters, and over 1500 staff.

Contact Me

Hot Searches