- Product Details

- {{item.text}}

Quick Details

-

Printing:

-

Polyester Screen Printing

-

Monofilament Style:

-

Yes

-

Place of Origin:

-

Hebei, China

-

Name:

-

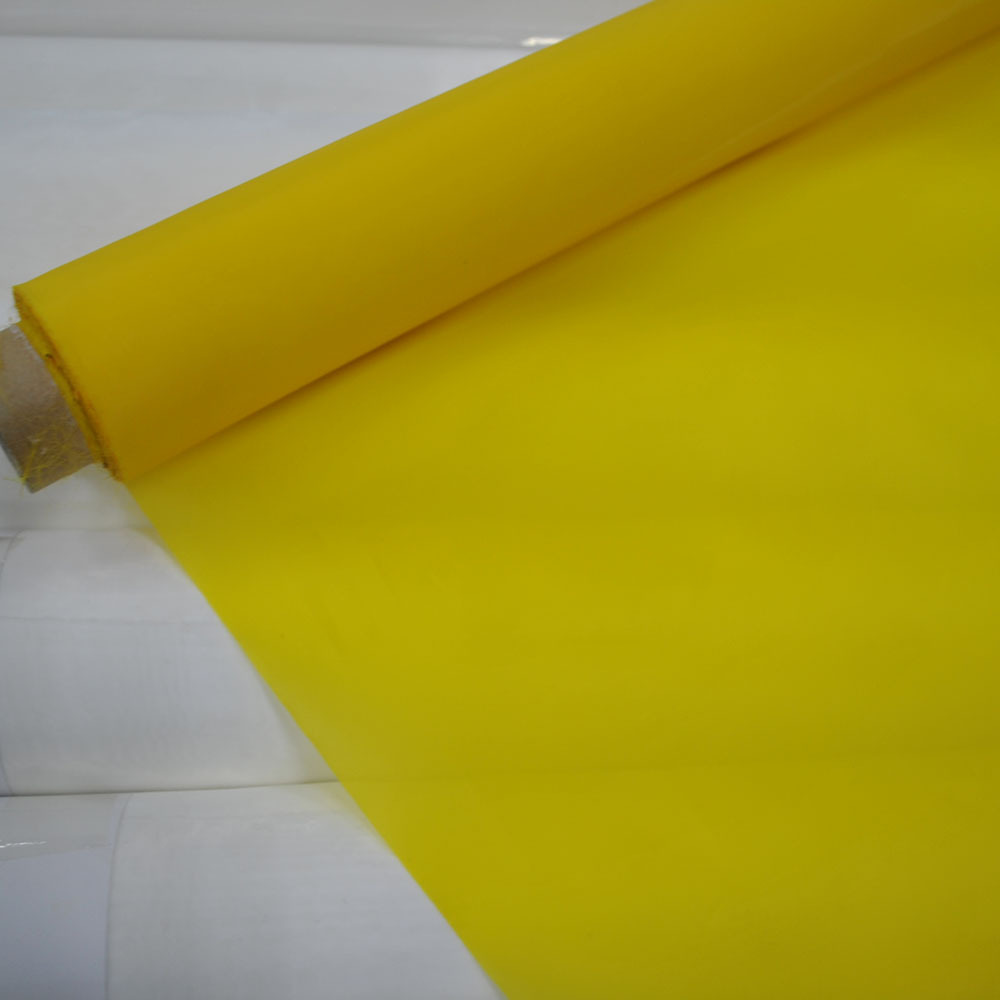

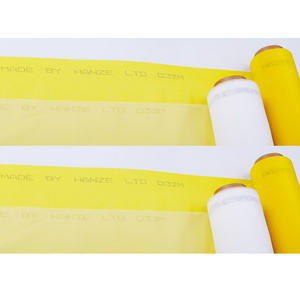

140 micron DPP silk screen printing mesh

-

Color:

-

white,yellow

-

Experience:

-

Since 1987

-

Machine:

-

Sulzer looms

-

Feature:

-

High tension

-

Length/roll:

-

50m in standard,or make to order

Quick Details

-

Material:

-

100% Polyester

-

Weave Type:

-

Plain

-

Elasticity:

-

Low

-

Printing:

-

Polyester Screen Printing

-

Monofilament Style:

-

Yes

-

Place of Origin:

-

Hebei, China

-

Name:

-

140 micron DPP silk screen printing mesh

-

Color:

-

white,yellow

-

Experience:

-

Since 1987

-

Machine:

-

Sulzer looms

-

Feature:

-

High tension

-

Length/roll:

-

50m in standard,or make to order

140 micron DPP silk screen printing mesh

Brief introduction:

Material:100%polyester monofilament

Weaving type: plain weaving

Mesh count:70 mesh

Thread diameter:140 micron

Width:105cm to 365 cm

Features and advantages:

- We choose the imported raw material wire or domestic high quality thread,weaving machine from Sulzer Ruti in Swiss.

- Strictly production line.

- At least three times tests to make sure the products quality.

- High durability and good to use.

- Easy to wash.

Applications:

This kind of silk screen printing mesh

is widely used in filteration and printing field.

1) Filteration: Widely used in areas as filtration and separation industry. Such as food industry for

milling filtering and flour milling, paper making factory and other grains milling. Like glucose production,

milk powder, soybean milk etc.

2) Liquid & Dust filtration (Filters, Filter Bags, Dust Filter Bags)

3) Printing: Widely used in textile printing, garment printing, glass printing, PCB printing, etc.

Production flow:

Weaving preparation→warping→weaving→initial commodity inspection→cleaning→heat setting →final commodity

inspection→entering market.

Our workshop:

Specification:

|

Specification |

|||||||

|

Model |

Mesh/cm |

Mesh/inch |

Aperture

|

Thread Dia.

|

Open Area

|

Thickness

|

Theoretical Ink

|

|

10-250 |

10 |

25 |

743 |

250 |

55 |

495 |

274 |

|

12-140 |

12 |

30 |

686 |

140 |

68 |

277 |

189 |

|

13-150 |

13 |

33 |

619 |

150 |

64 |

300 |

128 |

|

16-140 |

16 |

40 |

461 |

140 |

58 |

238 |

139 |

|

21-80 |

21 |

55 |

296 |

80 |

69 |

120 |

79 |

|

21-150 |

21 |

55 |

326 |

150 |

46 |

260 |

118 |

|

22-80 |

22 |

56 |

356 |

80 |

66 |

136 |

90 |

|

24-80 |

24 |

60 |

320 |

80 |

63 |

136 |

86 |

|

24-100 |

24 |

60 |

316 |

100 |

57 |

170 |

65 |

|

28-140 |

28 |

70 |

217 |

140 |

40 |

195 |

76 |

|

32-55 |

32 |

80 |

257 |

55 |

67 |

103 |

67 |

|

32-64 |

32 |

80 |

248 |

64 |

63 |

95 |

56 |

|

32-100 |

32 |

80 |

212 |

100 |

46 |

170 |

73 |

|

36-90 |

36 |

92 |

183 |

90 |

44 |

150 |

65 |

|

39-55 |

39 |

100 |

177 |

55 |

56 |

88 |

55 |

|

43-80 |

43 |

110 |

149 |

80 |

41 |

130 |

53 |

|

47-55 |

47 |

120 |

152 |

55 |

51 |

88 |

48 |

|

48-70 |

48 |

122 |

133 |

70 |

41 |

115 |

47 |

|

53-55 |

53 |

135 |

133 |

55 |

50 |

86 |

42 |

|

54-64 |

54 |

137 |

115 |

64 |

39 |

100 |

39 |

|

54-70 |

54 |

137 |

109 |

70 |

35 |

116 |

40 |

|

61-64 |

61 |

155 |

90 |

64 |

31 |

101 |

30 |

|

64-55 |

64 |

160 |

98 |

55 |

38 |

98 |

36 |

|

64-64 |

64 |

160 |

85 |

64 |

30 |

115 |

34 |

|

68-55 |

68 |

175 |

85 |

55 |

34 |

85 |

28 |

|

68-64 |

68 |

175 |

78 |

64 |

28 |

105 |

30 |

|

72-48 |

72 |

182 |

90 |

48 |

36 |

78 |

33 |

|

72-55 |

72 |

182 |

85 |

55 |

30 |

90 |

27 |

|

80-48 |

80 |

200 |

72 |

48 |

33 |

74 |

25 |

|

90-48 |

90 |

230 |

56 |

48 |

25 |

78 |

19 |

|

100-40 |

100 |

255 |

58 |

40 |

33 |

63 |

21 |

|

110-40 |

110 |

280 |

48 |

40 |

27 |

64 |

17 |

|

120-31 |

120 |

305 |

49 |

31 |

35 |

49 |

17 |

|

120-34 |

120 |

305 |

45 |

34 |

30 |

55 |

16 |

|

130-34 |

130 |

330 |

40 |

34 |

27 |

55 |

15 |

|

140-31 |

140 |

355 |

36 |

31 |

26 |

48 |

12 |

|

140-34 |

140 |

355 |

31 |

34 |

20 |

53 |

10 |

|

150-31 |

150 |

380 |

32 |

31 |

23 |

49 |

11 |

|

150-34 |

150 |

380 |

23 |

34 |

13 |

55 |

6.5 |

|

165-31 |

165 |

420 |

23 |

31 |

15 |

48 |

7 |

|

Note: The above theoretic data is for reference only,and thickness tollerance |

|||||||

Our test report:

FAQ: