- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

BINBAO

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

7500*2300*1800

-

Weight:

-

4000 kg

-

Product name:

-

Paper Roll To Sheets Cutting Machine

-

Function:

-

Cutting Paper

-

Model:

-

SCL-1100-2roll

-

Cutting speed:

-

150 cuts per minute

-

Automatic Grade:

-

Full Automatic

-

Finished Products:

-

Paper Sheets

-

Cutting way:

-

Guillotine Knife Cutting

-

Cutting width:

-

1100mm

-

Paper pressing style:

-

Cylinder

-

Certification:

-

CE

Quick Details

-

Type:

-

Paper Cutting Machine

-

Production Capacity:

-

150 m/min

-

Max. workable width:

-

1800mm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

BINBAO

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

7500*2300*1800

-

Weight:

-

4000 kg

-

Product name:

-

Paper Roll To Sheets Cutting Machine

-

Function:

-

Cutting Paper

-

Model:

-

SCL-1100-2roll

-

Cutting speed:

-

150 cuts per minute

-

Automatic Grade:

-

Full Automatic

-

Finished Products:

-

Paper Sheets

-

Cutting way:

-

Guillotine Knife Cutting

-

Cutting width:

-

1100mm

-

Paper pressing style:

-

Cylinder

-

Certification:

-

CE

Product Description

CE Approved High Quality MG Thin Tissue Paper Sheet Cutting Machine For Posters With Custom Conveyor Table

Usage:

Due to the MG tissue paper is thin and slight,it is difficult to cut roll into size sheets.The gsm range from 14-35gsm MG paper should be cut by straight blade. Rotary knife blade sheeter machine can’t work for cutting MG tissue paper.The finished cutting paper sheets are easy to fly up in the air. A device should be designed in the blade press paper sheets against in the

collecting&conveyor table.

SCL model paper roll to sheets cutting machine is special suitable to cut thin and light MG tissue paper roll into size sheets.The model machine equipped conveyor belt table,machine don’t stop when operators collect finished cutting sheets. The automatic counting function help you to easily pack sheets into reams.The model machine has one roll feeding,two rolls and four rolls as options to improve producing capacity.

collecting&conveyor table.

SCL model paper roll to sheets cutting machine is special suitable to cut thin and light MG tissue paper roll into size sheets.The model machine equipped conveyor belt table,machine don’t stop when operators collect finished cutting sheets. The automatic counting function help you to easily pack sheets into reams.The model machine has one roll feeding,two rolls and four rolls as options to improve producing capacity.

We had export the model machine to India,Vietnam, Indonesia, Thailand, Malaysia, UAE, Egypt, Algeria, Tunisia, and so on country customers. They can use the Binbao company SCL series paper sheets cutting machine to cut MG tissue paper sheets, Using it to wrap and pack products,such as shoes,clothes,fruit,leather,bags,gift,flowers,sugar. Because the acid free MG tissue paper is very safety for food.

Feature:

1. Machine Rack: The machine rack adopt Shanghai BaoSteel company as steel raw material. 16mm thickness machine body wall make the machine more stronger and running more stable at high speeds.

2. Aluminum Rollers: All aluminum rolls installed in machine are being dynamic balance testing. Material can smoothly move in these rollers without any scratching.

3. PU-Rollers: The PU rollers are high abrasive resistance,which can insure machine feeding precision.

4. Cylinder Lifter: The jumbo roll material can be easy lift up by the cylinder from the ground. Save labor and easily operating the cutting machine.

5. Motors: The machine adopt one set servo motor and two sets asynchronous motors to drive.It make the machine working with a high level cutting precision(0.2mm error range)

6. Control System: The SCN series paper cutting machine adapt intelligent and easy operating control system with Japanese brand PLC. It have automatic counting sheets,automatic stop machine after cutting per batch,automatic detect mother rolls diameter,automatic tension control and so on functions. In the touch screen,you also can check machine working condition parameters.

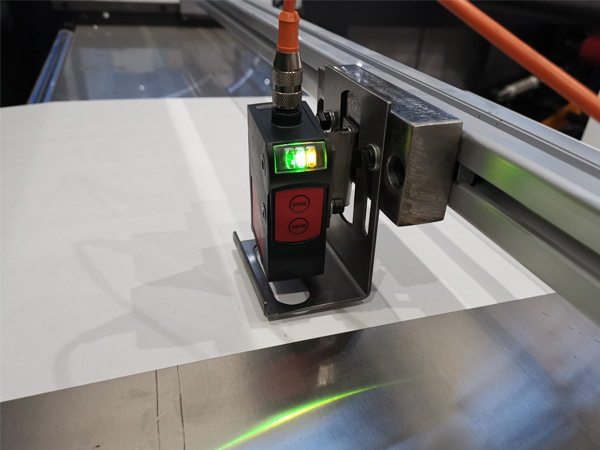

7. Static Elimination:The machine have statics bar to eliminate the statics influence.

8. Automatic counting: The machine will automatic count the cutting sheets quantity and stop when it reach your desired sheets quantity setting in the PLC.

9. Non stop: When the operator collect the finished cutting sheets, the machine won’t stop and continue cut paper sheets.

2. Aluminum Rollers: All aluminum rolls installed in machine are being dynamic balance testing. Material can smoothly move in these rollers without any scratching.

3. PU-Rollers: The PU rollers are high abrasive resistance,which can insure machine feeding precision.

4. Cylinder Lifter: The jumbo roll material can be easy lift up by the cylinder from the ground. Save labor and easily operating the cutting machine.

5. Motors: The machine adopt one set servo motor and two sets asynchronous motors to drive.It make the machine working with a high level cutting precision(0.2mm error range)

6. Control System: The SCN series paper cutting machine adapt intelligent and easy operating control system with Japanese brand PLC. It have automatic counting sheets,automatic stop machine after cutting per batch,automatic detect mother rolls diameter,automatic tension control and so on functions. In the touch screen,you also can check machine working condition parameters.

7. Static Elimination:The machine have statics bar to eliminate the statics influence.

8. Automatic counting: The machine will automatic count the cutting sheets quantity and stop when it reach your desired sheets quantity setting in the PLC.

9. Non stop: When the operator collect the finished cutting sheets, the machine won’t stop and continue cut paper sheets.

Specification

|

MAIN PARAMETERS OD SCL SHEETS CUTTING MACHINE

|

|

|

|

|||

|

Model Name

|

SCL-1100

|

SCL-1400

|

SCL-1800

|

|||

|

Mother Roll Width(Max)

|

1100mm

|

1400mm

|

1800mm

|

|||

|

Mother Roll Diameter(Max)

|

Φ1500mm

|

Φ1500mm

|

Φ1500mm

|

|||

|

Mother Roll Weight Capacity

|

1200kg

(2000kg optional) |

1200kg

(2000kg optional) |

1200kg

(2000kg optional) |

|||

|

Paper Core Size

|

3/6 inch

|

3/6 inch

|

3/6 inch

|

|||

|

Cutting Length

|

20-800mm

|

20-800mm

|

20-800mm

|

|||

|

Thickness Range

|

18-400gsm

|

18-400gsm

|

18-400gsm

|

|||

|

Cutting Precision

|

±0.2mm

|

±0.2mm

|

±0.2mm

|

|||

|

Cutting Speed

|

150 cuts per minute

|

150 cuts per minute

|

150 cuts per minute

|

|||

Application

Case One: Sticker paper sheets

Case Two: Shopping paper bags

Case Three: Plastic film

Case Four: Blue drawing paper

Customer Factory Photos

After Sales Service

Packing & Delivery

Hot Searches

![[JT-SM1900]CE Certificated Sandwich Paper Cutting Machine A4 Paper Cutting And Packing Machine Paper Roll To Sheet Cutter](https://cdn.bestsuppliers.com/seo_products_img/jeta/9685a4f9a2463817992b2ef0b1a0b03a.jpg!/rotate/180/sq/300)