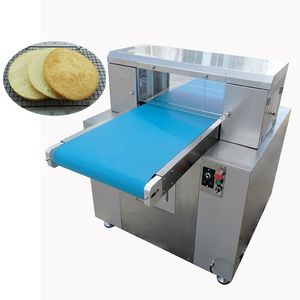

For the round, rectangular and other shapes of bread, cakes, pizza and other baked goods for a variety of shapes of cutting function.

*

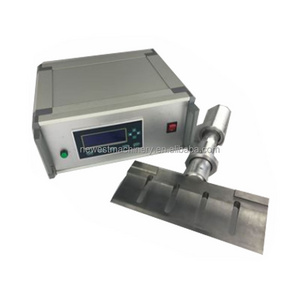

Control system:

With Siemens control system as the core, the cutting control system includes automatic mode, manual mode,

circular cutting mode, square cutting mode, triangle cutting mode, diamond cutting mode in one, to achieve accurate cutting of

various products, to achieve a multi-purpose machine, improve cutting efficiency.

*

Driving device:

The driving device adopts high-precision servo control system, combined with Siemens control system, which can accurately achieve high-precision cutting position control.

*

Touch screen:

High-performance industrial touch screen, can quickly respond to a variety of cutting methods of data conversion.

*

Safety protection:

Equipped with infrared sensor protection device to ensure the safety of operators.

*

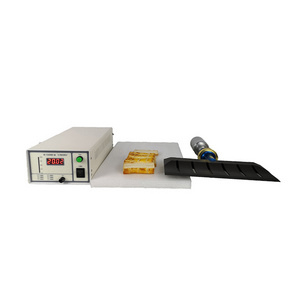

Ultrasonic system:

Titanium alloy blade with digital generator, automatic frequency tracking and real-time tracking frequency.