- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

custom

-

Type:

-

moule injection plastique

-

Mould base:

-

LKM.HASCO

-

Keyword:

-

moule injection plastique

-

Mould material:

-

P20/718/738/NAK80/S136/2738/2316

-

Mould life:

-

100,000-300,000shots

-

Material:

-

ABS/PA66/PP/PC/PMMA/PSU/PCTG/TPE/TPU/PBT

-

Cavity:

-

Singl / Muti Cavity

-

Runner:

-

Hot Runner\ Cold Runner

-

Certification:

-

ISO9001:2015

-

Product Name:

-

High precision OEM moule injection plastique

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OEM

-

Model Number:

-

custom

-

Type:

-

moule injection plastique

-

Mould base:

-

LKM.HASCO

-

Keyword:

-

moule injection plastique

-

Mould material:

-

P20/718/738/NAK80/S136/2738/2316

-

Mould life:

-

100,000-300,000shots

-

Material:

-

ABS/PA66/PP/PC/PMMA/PSU/PCTG/TPE/TPU/PBT

-

Cavity:

-

Singl / Muti Cavity

-

Runner:

-

Hot Runner\ Cold Runner

-

Certification:

-

ISO9001:2015

-

Product Name:

-

High precision OEM moule injection plastique

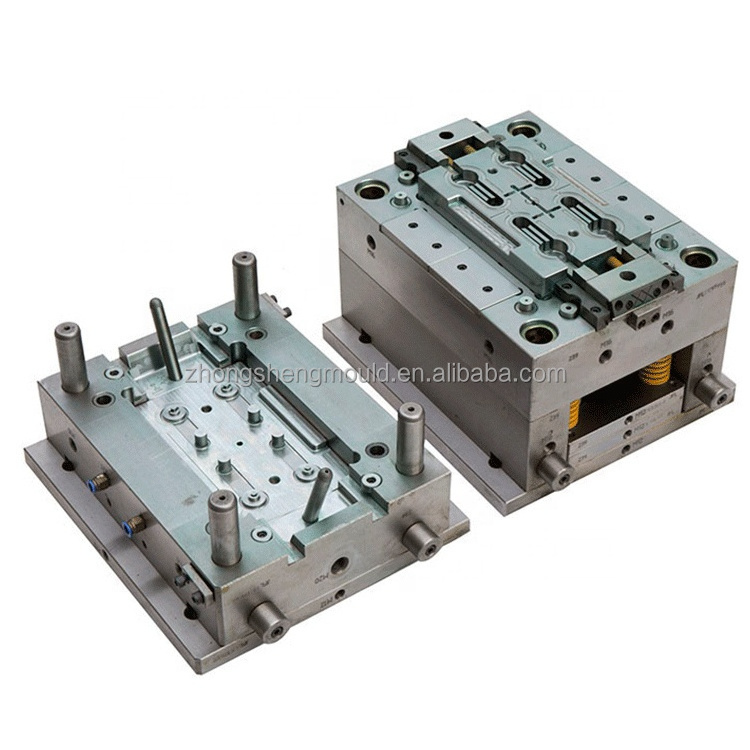

Products Description

|

Product Name

|

High Quality Plastic Injection Mold and Molding Manufacturer

|

|

|

|

|||

|

Mold Material

|

S136/2344/718/738/NAK80/P20, etc.

|

|

|

|

|||

|

Plastic Material

|

ABS, PP, PC, PVC, POM, TPU, PC, PEEK,HDPE,NYLON, Silicone, Rubber, etc

|

|

|

|

|||

|

Mold Base

|

LKM, HASCO, etc.

|

|

|

|

|||

|

mold Life

|

3k-800k shots (depend on your environment)

|

|

|

|

|||

|

Mould Precision

|

+/-0.01mm

|

|

|

|

|||

|

Mould Cavity

|

Single cavity, multi-cavity.

|

|

|

|

|||

|

Runner System

|

Hot runner and cold runner

|

|

|

|

|||

|

Sureface Treatment

|

Polishing/smooth,texture/frosted, painting, plating, printing , etc.

|

|

|

|

|||

|

File Format

|

STEP, STP, STL, X-T, IGS, PDF,JPG,etc.

|

|

|

|

|||

|

Custom Feature

|

According to your 2D/3D Drawing or sample provided

|

|

|

|

|||

|

Quality Assurance

|

ISO9001: 2015, SGS, ROHS, TUV,etc

|

|

|

|

|||

|

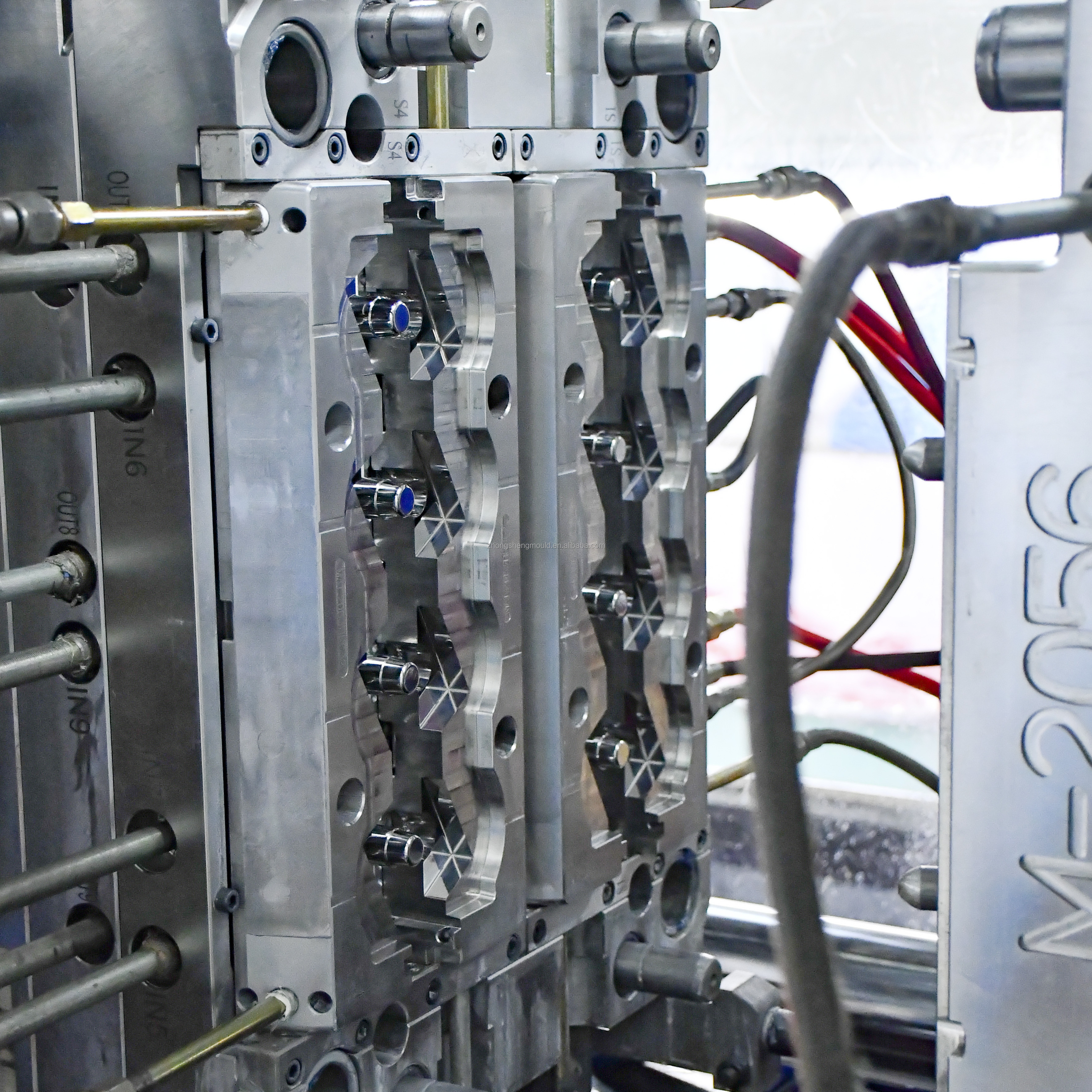

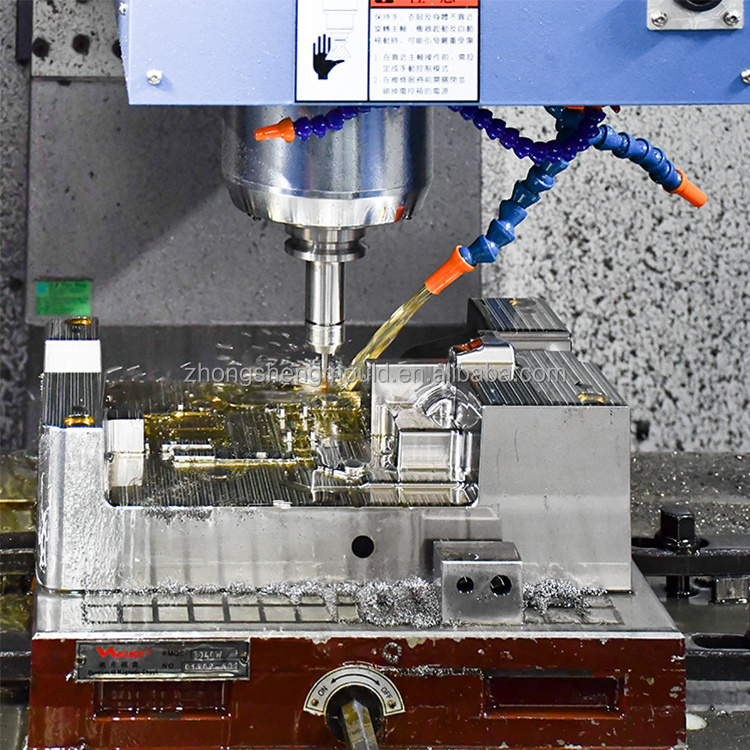

Our Equipments

|

High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine from 30-1400T available.

|

|

|

|

|||

|

Main Field

|

Home appliance, Medical device, Electronic device, Automotive parts, Tele-communication, Lighting control equipment, digital device, Robots, etc.

|

|

|

|

|||

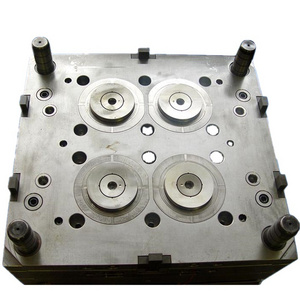

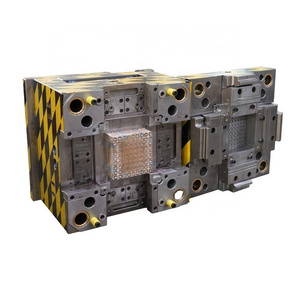

Plastic Molds

Plastic Injection Parts

Manufacturing Technique

Zhonghesheng moul

d

can custom to make mold and molding according to customers' drawing design(2d or 3d), or their samples within two days to give a quotation. We can provide customers with satisfactory molds and high quality plastic parts, and guarantee the long life of molds. So if you have a dream,please kindly contact us for more details.

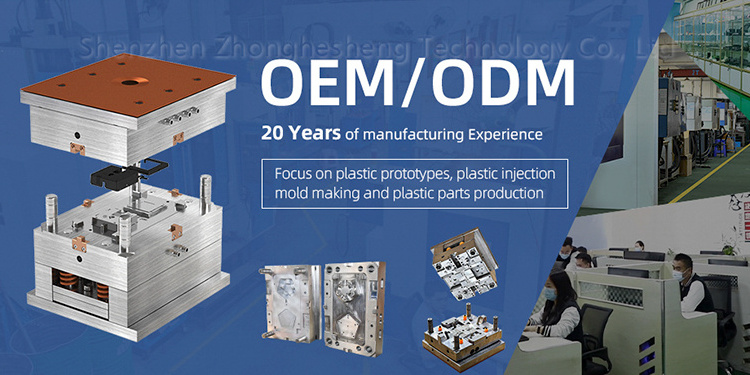

Our Company

Shenzhen Zhonghesheng Technology Co., Ltd.

Zhonghesheng mould was f

ounded in 2002, covering 3,500 square meters, having more than 100 staff.Most of them are senior managerial and technical personnel.

Zhonghesheng mould specialized in plastic injection mold and molding, rubber and silicone mold and products, die-casting mold and parts etc.Our Products are widely applied in the area of Home Appliances, Electronics, Automotive, Tele-communication, Medical Devices, etc. All orders strictly follows ROHS standards, which can meet the quality requirements of different industries.

Customer Photos

Product packaging

Package details: Wooden box for plastic mold, and carbon box for plastic products.

Delivery details: 15-25 days for mold making, and parts lead time depends on the quantity.

FAQ

Q1: Are you a trading company or factory?

A: We are direct factory with more than 100 employees as well approximate 3,500 square meters workshop area, in Shenzhen, China.

Q2: How can I get the quotation?

A: We will submit the quotation in 24 hours if getting detailed information during working days. In order to quote for you earlier, please provide us the following information together with your inquiry:

1)3D Step of Files and 2D Drawings

2) Material requirement

3) Surface treatment

4) Quantity (per order/per month/annual)

5) Any special demands or requirements, such as packing, labels, delivery, etc.

Q3: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q4: Do you provide samples? Is it free or extra?

A: Yes we offer free sample but do not afford the shipping cost.

Q5: ls your company currently participating in any Customer Certification Program?

A: 3C certification, REACH,ROHS,PRO65.

Q6: Do you provide assembly service?

A: We offer products design and 3D print service, we have 15 injection machines and 2 assembly lines, we can provide production run and assembly service.

Q7: How do you provide after-sales service?

A: We provide after-sales service within two years after per customer receives the mold. If the mold is damaged within two years, we can send the new replacement mold fittings for free.

Hot Searches