- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

12700 KG

-

Applicable Industries:

-

waste sawdust factory

-

Product name:

-

wood pallet making machine

-

Key words:

-

wood pallet making machine

-

Function:

-

produce Molded pallets

-

Raw material:

-

waste wood ,bamboo and glue

-

Capacity:

-

130-160PCS/day

-

Main motor Power:

-

7.5KW

-

Applicable mold type:

-

less than 1300*1250 or customized

-

Heating source:

-

thermal oil or steam

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

CHRYSO

-

Machine Type:

-

pallet making machine

-

Weight (KG):

-

12700 KG

-

Applicable Industries:

-

waste sawdust factory

-

Product name:

-

wood pallet making machine

-

Key words:

-

wood pallet making machine

-

Function:

-

produce Molded pallets

-

Raw material:

-

waste wood ,bamboo and glue

-

Capacity:

-

130-160PCS/day

-

Main motor Power:

-

7.5KW

-

Applicable mold type:

-

less than 1300*1250 or customized

-

Heating source:

-

thermal oil or steam

Product Description

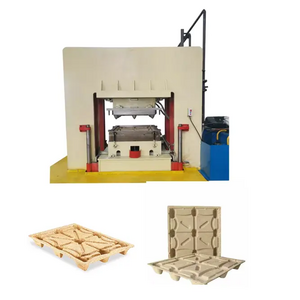

The

compressed wood pallet machine

is used for pressing and forming wood chips, straw, waste chemical fiber and other raw materials.There is an independent hydraulic system in this equipment.

The compressed wood pallet making machine has the advantages of good stability performance,high efficiency,and energy saving.What is more,the compressed wood pallet is fumigation free and no limit for international transportation.

The press machine can use both the steam and the thermal oil as heating source.

The pallet press machine is very convenient for installation and do not need basic positioning.You can produce different wood pallet size and pallet design by changing the mold.

The compressed wood pallet making machine has the advantages of good stability performance,high efficiency,and energy saving.What is more,the compressed wood pallet is fumigation free and no limit for international transportation.

The press machine can use both the steam and the thermal oil as heating source.

The pallet press machine is very convenient for installation and do not need basic positioning.You can produce different wood pallet size and pallet design by changing the mold.

Raw materials

The compressed wood pallet making machine mainly use the Bamboo shavings, wood sawdust, wood shavings, scrap materials as main raw materials.

End Products of Compressed Wood Pallet Machine :

The pictures of wood pallet making macine different molds :

The pallet mold is customized basis on your request and we also can provide the design for your choice.The normal pallet size is 1200*800mm,1200*1000mm,1200*1100mm and so on. Our engineer will draw pallet mold CAD for your checking.

Specification

|

Model

|

CRS-800T

|

|

Pressure

|

800T or customized

|

|

Main cylinder

|

Φ320,4 sets

|

|

Pilot oil cylinder

|

Φ100,1 set

|

|

Lift cylinder

|

Φ100,2 sets

|

|

Main motor power

|

7.5KW

|

|

Press stroke

|

550mm

|

|

Capacity

|

130-160Pcs/Day

|

|

Mold type

|

less than 1300*1250mm or customized

|

|

Heating type and capacity

|

Steam or thermal oil,0.15 Cubic metre

|

|

Machine size

|

2300*1500*4300mm

|

|

Machine weight

|

12700kg

|

Product Features

Features of our compressed wood pallet making machine :

1. Our wood pallet machine has a good structure ,it use the three-way synchronous positioning,precision and balance,the pressurize will be soon when filling ,the pressurize will be fine within 35 seconds.

2. It is easy to operate ,just press the work button,then the machines will complete the whole process automatically.

3. It needs about 450 seconds to molding a tray .

4. The machine can produce about 130-160 PCS pallet per day .

5. The density of the pallet is about 900kg per cubic meter.

6. The machine can be customized

1. Our wood pallet machine has a good structure ,it use the three-way synchronous positioning,precision and balance,the pressurize will be soon when filling ,the pressurize will be fine within 35 seconds.

2. It is easy to operate ,just press the work button,then the machines will complete the whole process automatically.

3. It needs about 450 seconds to molding a tray .

4. The machine can produce about 130-160 PCS pallet per day .

5. The density of the pallet is about 900kg per cubic meter.

6. The machine can be customized

Whole Production Line

The whole compressed wood pallet production line :

Providing electric thermal boiler machine for whole automatic production line:

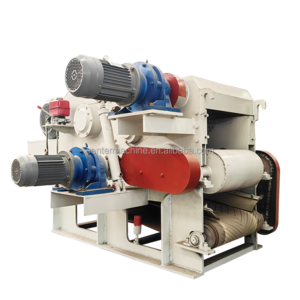

Step 1 : crushing the materials into 5mm.

Step 2 : If raw materials with high moisture, dry them to about12% moisture content.

Step 3 : Mix the dried materials with glue according to a certain proportion.( Metering electric glue mixer machine for mixing the sawdust and glue )

Step 1 : crushing the materials into 5mm.

Step 2 : If raw materials with high moisture, dry them to about12% moisture content.

Step 3 : Mix the dried materials with glue according to a certain proportion.( Metering electric glue mixer machine for mixing the sawdust and glue )

Step 4

: Fill the mixed materials into the mould and press.

Step 5 : Keep pressing for 7-10 minutes, then the finished pallet can be gotten.

Auto feeding and discharging conveyor for pallet press machine.

Step 5 : Keep pressing for 7-10 minutes, then the finished pallet can be gotten.

Auto feeding and discharging conveyor for pallet press machine.

Our factory

Hot Searches