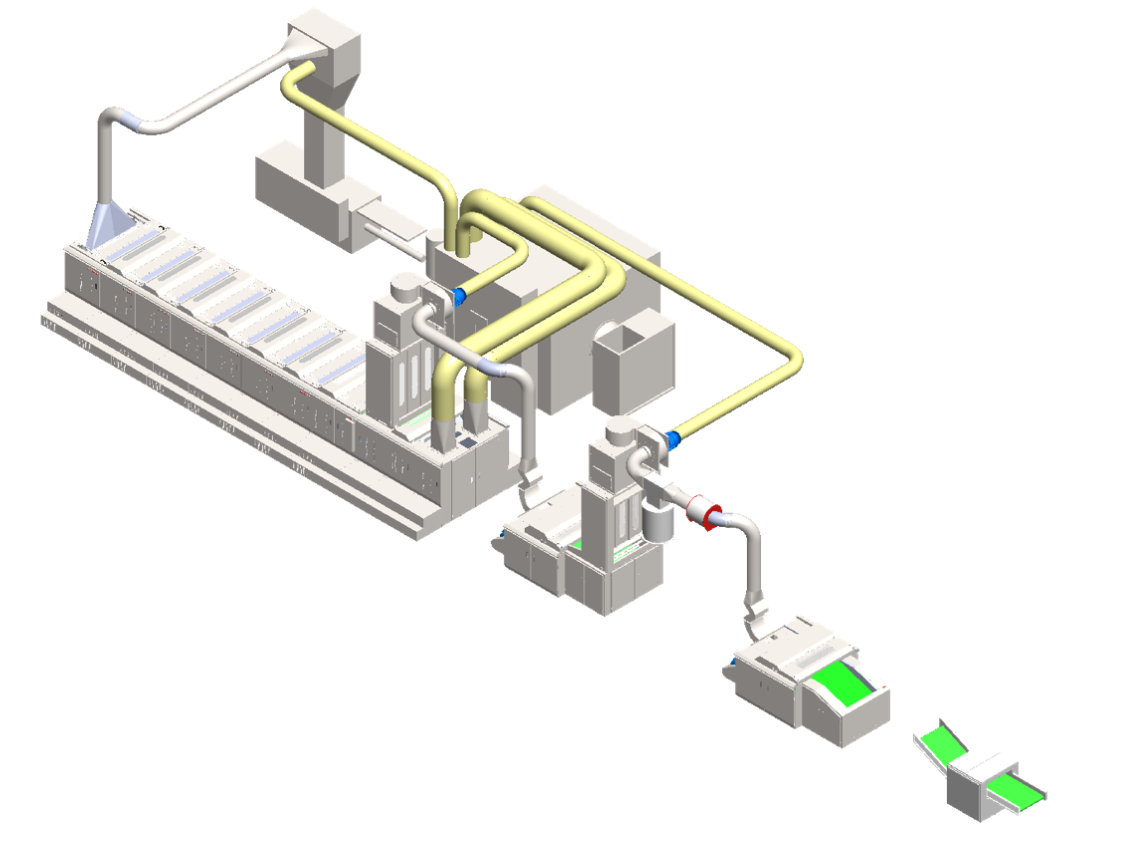

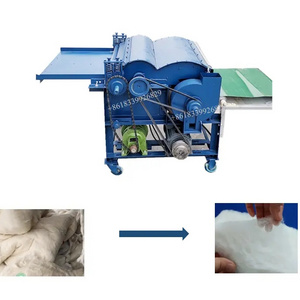

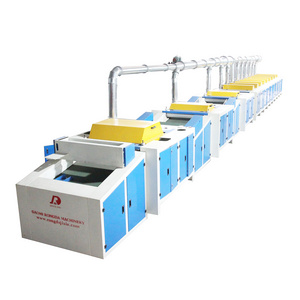

Feed more smooth, can reduce the cross section of raw material, effectively protect fiber length.

Using high strength pegboard type and wire type licker-in to provide professional processing solutions for different raw materials.

Using no dust cage exiting unit, high productivity and low failure rate.