This loading frame decoiler also can use in other type machine, customer can buy it alone.

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

China

-

Weight:

-

2500 kg, 8.0 T

-

Name:

-

glazed roof tile roll forming machine line

-

Dimension(L*W*H):

-

7.5m*1.3m*1.3m

-

Diameter of Shafts:

-

80 mm

-

Material of Shafts:

-

45# Steel

-

Number of Rollers:

-

13+15

-

Material Thickness:

-

0.3-0.8 mm

-

Roller Fixer:

-

Middle Plate

-

Machine Frame:

-

300 H Steel Welded

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15m/min

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

China

-

Weight:

-

2500 kg, 8.0 T

-

Name:

-

glazed roof tile roll forming machine line

-

Dimension(L*W*H):

-

7.5m*1.3m*1.3m

-

Diameter of Shafts:

-

80 mm

-

Material of Shafts:

-

45# Steel

-

Number of Rollers:

-

13+15

-

Material Thickness:

-

0.3-0.8 mm

-

Roller Fixer:

-

Middle Plate

-

Machine Frame:

-

300 H Steel Welded

Product Overview

Product Overview

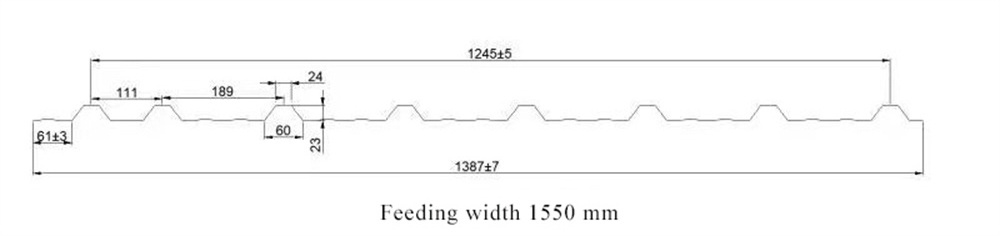

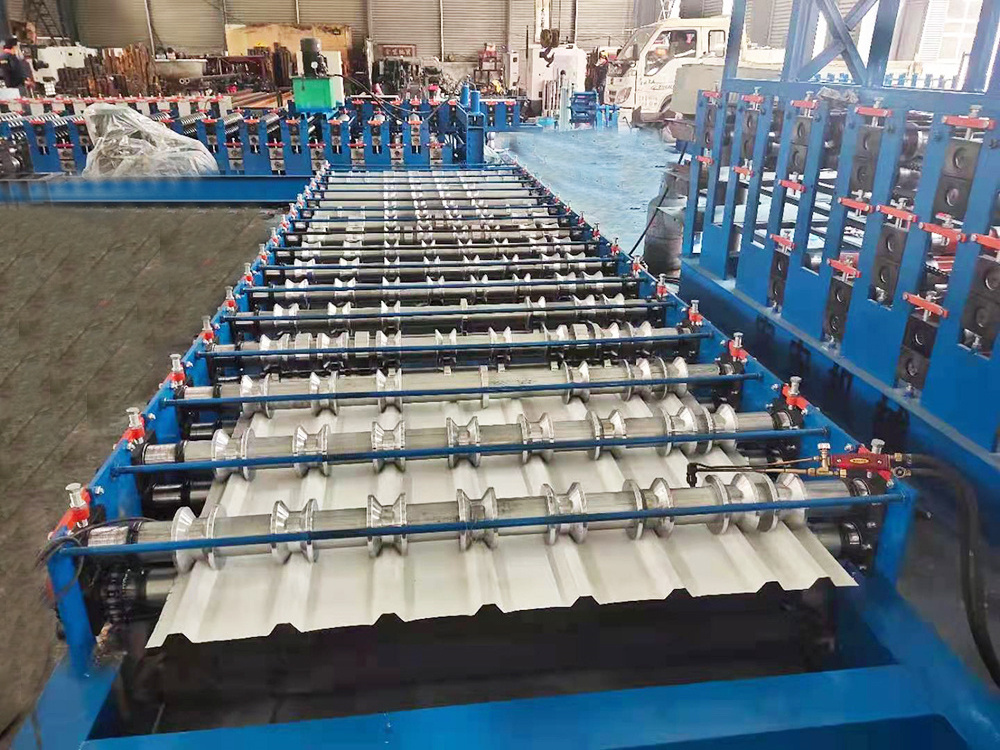

IBR Trapezoidal Roof Sheet Make Machine

IBR Trapezoidal Roof Sheet Make Machine metal roll forming roof sheet making machine,it is our company most popular products in building materials machine. For roof sheet, it include many type according to its different shape, popular type include corrugated tile roll forming machine, trapezoidal tile roll forming machine,glazed tile roll forming machine, ridge cap roll forming machine and other type profile panel roll forming machine.

When you choose roof sheet making machine, you had better learn popular shape in local,also raw material is an important considering data, if do not have good supplier in local, we can assist you purchase it in China together. we are professional factory and in this area for many years, any requires please contact us at any time!

PRODUCT SPECIFICATIONS

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

|

1

|

Raw material width

|

1000-1200 mm

|

|

2

|

Sheet effective width

|

750-1000 mm

|

|

3

|

Raw material

|

Color steel sheet or galvanized steel sheet

|

|

4

|

Material thickness

|

0.3-0.8 mm or customized

|

|

5

|

Forming roller material

|

45# steel plated with chrome

|

|

6

|

Shaft diameter

|

70 mm

|

|

7

|

Forming roll station

|

8-16 steps

|

|

8

|

Main motor power

|

3 KW 4 KW 5.5 KW(according to type)

|

|

9

|

Hydraulic power

|

4 KW (according to type)

|

|

10

|

Control system

|

PLC control

|

Details Images

Details Images

Decoiler

Roof sheet make machine load parts, decoiler loading frame we can offer different type can choose. standard type are manual,also can choose electric loading frame or hydraulic loading frame.

Machine frame

Roof sheet make machine adopts welded steel frame structure, it make sure roof sheet machine can operation more stable

AC frequency conversion motor reducer drive, chain transmission, roller surfaces polishing,

hard plating, heat treatment and chrome coating.

hard plating, heat treatment and chrome coating.

Forming roller

Roof sheet make machine forming roll quality will decide roof sheet shapes, we can according to your local roof shape customized different type rollers

Roller chrome coated thickness: 0.05 mm

Roller material: Forging Steel 45# heat treatment.

Control part

Roof sheet make machine control parts have different types, standard type are button control, through press buttons to realize different function.

PLC touch screen type can setting data on the screen, its price is little higher, but is more intelligent and automatic.

Successful Project

Successful Project

Project in Thailand

Project in India

Project in Russia

Hot Searches