- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

CY-Auto-mould0002

-

Name:

-

wheel cover injection mould

-

Mould Material:

-

P20.718HH, 2738 ,H13, 45#,C50 ect

-

Mould Base:

-

LKM.HASCO,ect

-

Cavity:

-

Single/Multi

-

Runner:

-

Cold /Hot

-

Mould Life:

-

300,000-500,000shots

-

Design Software:

-

UG ,Proe ,CAD/CAM,ect

-

Delivery time:

-

45-60days

-

package:

-

wooden case

-

advantage:

-

reasonable price,high quality,on time delivery

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

CY Mould

-

Model Number:

-

CY-Auto-mould0002

-

Name:

-

wheel cover injection mould

-

Mould Material:

-

P20.718HH, 2738 ,H13, 45#,C50 ect

-

Mould Base:

-

LKM.HASCO,ect

-

Cavity:

-

Single/Multi

-

Runner:

-

Cold /Hot

-

Mould Life:

-

300,000-500,000shots

-

Design Software:

-

UG ,Proe ,CAD/CAM,ect

-

Delivery time:

-

45-60days

-

package:

-

wooden case

-

advantage:

-

reasonable price,high quality,on time delivery

|

Core &Cavity Steel |

P20,718H,2738H, H13, NAK80,2316 etc. |

|

Mould base & Standard Component |

DME,HASCO,Self-made etc. |

|

Steel hardness: |

HRC35-38 |

|

Plastic material |

PP,PC,PE,ABS,PVC etc. |

|

Cavity Number |

1*1 |

|

Injection System |

Side Gate,hot gate |

|

Ejector System |

Ejector Pin |

|

Cycle Time |

30-60S |

|

Tooling lead time |

45-60 Days |

|

Mould life |

500,000 Shots |

|

Quality assurance |

ISO9001 |

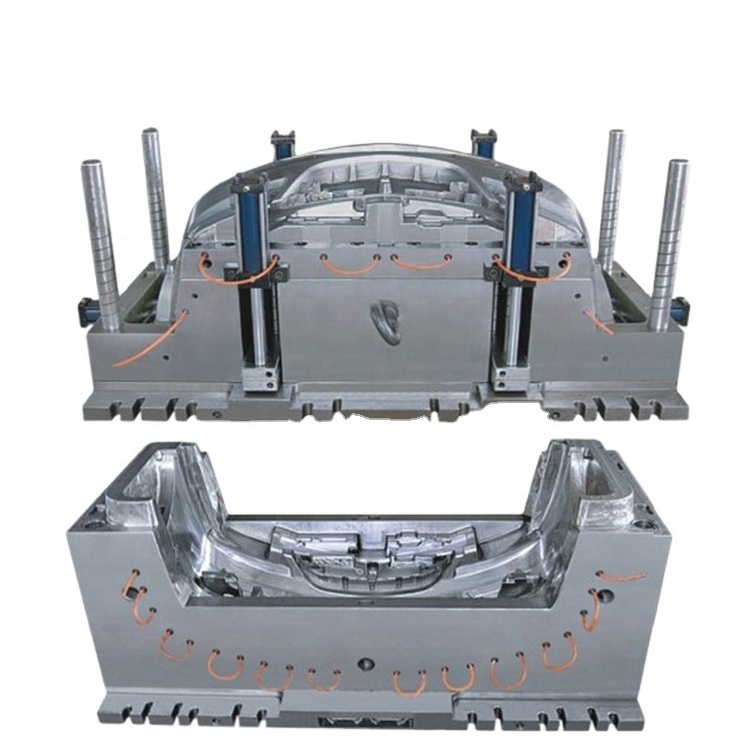

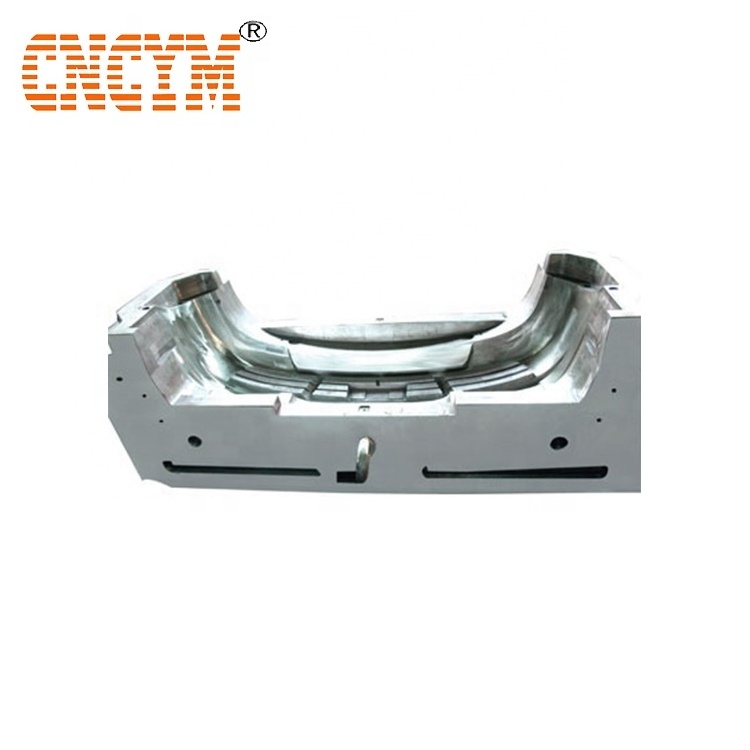

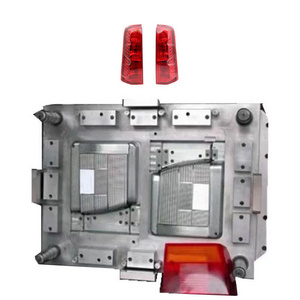

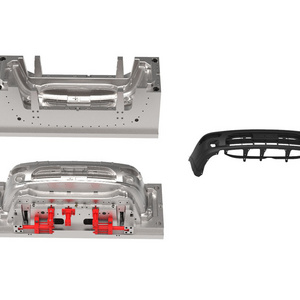

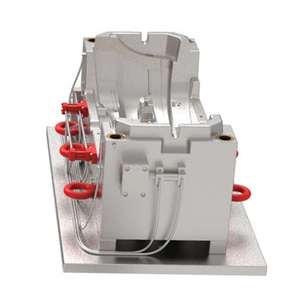

1.Photo of Plastic Injection Mold

In-time supply the quotation and mould deigns

In-time communication on the technical points

In-time sending pictures for the mould machining progress and mould finishing schedule

In-time mould delivery.

In-time mould test and sample delivery

2.Detail information of mould steel

| Mould material | mould hardness | mould life |

| P20 | HRC 29-33 | 300000 shot |

| H13 | HRC >43 | 1000000 shot |

| 718 | HRC 30-36 | 500000 shot |

| S136 | HRC 48-52 | 50000 shot |

| 2344 | HRC >48 | 800000 shot |

The flow chart of mould

|

Receiving the inquire |

|

We send the price offer or details to you within 16 hours |

|

Customers offer the 2D/3D drawing and some details about the mould |

|

Confirming the order (quality , price , material , delivery time , payment terms etc.) |

|

According to client’s requirement to prepare the production |

|

Clients confirm the details of the mould |

|

Surface shaping |

|

Drill holes , high speed carve machine ,wire cutting , EDM, etc. |

|

Arranging the test mould and sending the samples to customers |

|

If clients do not satisfy the samples , giving us advice , please |

|

Repair , Polish , Texture |

|

We will send clients the samples till the customers’ confirmation |

|

Delivering by sea or by air ,etc |