- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.1%

-

Voltage:

-

Customizable

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Honor Machine

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

5800 KG

-

Product name:

-

Aluminum Can Filling Machine

-

Capacity:

-

3000-20000BPH

-

Function:

-

Filling Packing

-

Suitable bottle:

-

Pop can / Aluminum can / Tin can

-

Bottle size:

-

100ml-1000ml

-

Machine material:

-

SUS304/316

-

Filling Liquid:

-

Carbonated / Juice Drink

-

Filling system:

-

Isobaric Filling Type

-

Control system:

-

PLC (SIEMENS)

-

After-sales Service Provided:

-

2 years

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH

-

Packaging Material:

-

Wood

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice, Powder

-

Filling Accuracy:

-

±0.1%

-

Voltage:

-

Customizable

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Honor Machine

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

5800 KG

-

Product name:

-

Aluminum Can Filling Machine

-

Capacity:

-

3000-20000BPH

-

Function:

-

Filling Packing

-

Suitable bottle:

-

Pop can / Aluminum can / Tin can

-

Bottle size:

-

100ml-1000ml

-

Machine material:

-

SUS304/316

-

Filling Liquid:

-

Carbonated / Juice Drink

-

Filling system:

-

Isobaric Filling Type

-

Control system:

-

PLC (SIEMENS)

-

After-sales Service Provided:

-

2 years

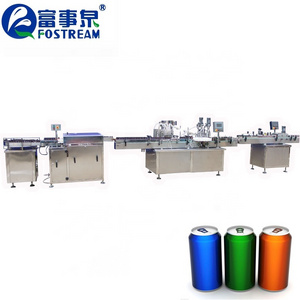

Product Description

GD Series Aluminum Can Filling Sealing Machine

The machine is mainly used for carbonated beverages,beer, Coca-Cola, gas-containing fruit wine etc. It adopts pneumatic control without tank contact to automatically lower the lid, and adopts Isobaric filling technology. The production capacity is variable frequency speed regulation, which ensures the beauty and hygiene requirements of the whole machine. To improve the vacuum in the tank, steam ejector can be equipped according to customer's requirements, and remote monitoring system can be equipped to ensure maximum technical support to customers. This equipment is used in the production of medium and large-scale production.

Different filling capacities

GD12-1 Aluminum Can Filling Sealing Machine Capacity:3000-5000 cans per hour.

GD18-4 Aluminum Can Filling Sealing Machine Capacity:6000-8000 cans per hour.

GD24-6 Aluminum Can Filling Sealing Machine Capacity:9000-12000 cans per hour.

GD30-6 Aluminum Can Filling Sealing Machine Capacity:13000-16000 cans per hour.

GD40-8 Aluminum Can Filling Sealing Machine Capacity:17000-20000 cans per hour.

Specification

|

Model

|

GD12-1

|

CGF14-12-5

|

GD18-4

|

GD24-6

|

GD30-6

|

GD40-8

|

|||||

|

Capacity(cans/h)

|

3000-5000

|

2000-4000

|

6000-8000

|

9000-12000

|

13000-16000

|

17000-20000

|

|||||

|

Total power(KW)

|

5.5

|

|

6.5

|

7.8

|

8.5

|

9.4

|

|||||

|

Overall dimensions(mm)

|

2800*1600*2000

|

|

3000*1700*2000

|

3200*1800*2000

|

3500*1950*2000

|

4000*2050*2200

|

|||||

|

Weight(kg)

|

3000

|

|

4000

|

4800

|

5200

|

6800

|

|||||

|

Suitable bottle shape

|

Pop can / Tin can / PET can

|

|

|

|

|

|

|||||

|

Can apply to high(mm)

|

65-190mm(Special height can be customized)

|

|

|

|

|

|

|||||

Details Images

1, Water Treatment System

Simple operation / Less maintenance / Lower power co

sumption

Water treatment system refers to the measures taken to make the water quality meet certain use standards. The physical characteristics of water, such as temperature, color, transparency, odor and taste, are filtered or treated so that water can be used directly for drinking or other purposes.

2.Processing System

Juice processing system:

Complete juice processing system is not only can be suitable for common products ,but also can satisfy special requirements of customers.

Carbonated drink processing system:

Carbonated beverage mixing system structure reasonable, mix precision is high, CO2 mixes fully, has two times of cooling, two carbonation merits.

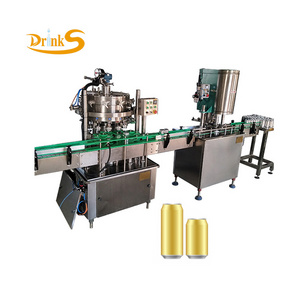

3,Can Filling Sealing 2-in-1 Machine

GD Series can filling and sealing machine is for carbonated beverage and juice industries ,it have such features as rapid filling and sealing speed ,consistent height from the liquid level in the can to the can mouth after filling ,stable machine operation ,good sealing quality ,beautiful and decent appearance ,convenient use and maintenance,touch screen operation ,frequency conversion speed adjustment ,etc.It is the most ideal filling and sealing device for beverage plants and brew houses.

Can Depalletizer

It can replace the manual can arrangement,increase production efficiency ,it is an indispensable ideal device for middle and large sized beverage plants, PLC Programmable computer automatic controller ,photo-electricity switch,over travel-limit switch and pneumatic control ,etc ,use the famous brand from Germany and Japan and Taiwan

4,Can Packing Machine

The machine adopt to servo location, PLC controlling, auto operation, main drive adopt to import motor drive, multi degree rotation via chain, chain wheel speed regulator ect. It auto degree is high, reliable controlling, easy to adjust, intelligentize manipulation ect advantage, can widely used for beverage, beer, chemistry, food, medicine ect industry, can do all kind of tin and bottle second time package, can match with auto filling production line.

Turnkey Solution

We are not only a filling equipment manufacturer, but also design and build factories, equipment layout, circuit layout and equipment operation schemes. Our equipment is designed carefully, easy to use and easy to manage. Whether you need a machine or a complete filling and packaging system, we have rich experience to ensure the successful completion of your project.

Similar Machine

Linear Type Aluminum Can Machine With Small Capacity 500-3000 cans per hour

Hot Searches