- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

60 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GS-mach

-

Voltage:

-

380V/3P

-

Dimension(L*W*H):

-

25*4.5*6.5

-

Power (kW):

-

110

-

Weight:

-

25 KG

-

Raw material:

-

PE PP PS PC ABS PMMA PET PLA PVDF

-

name:

-

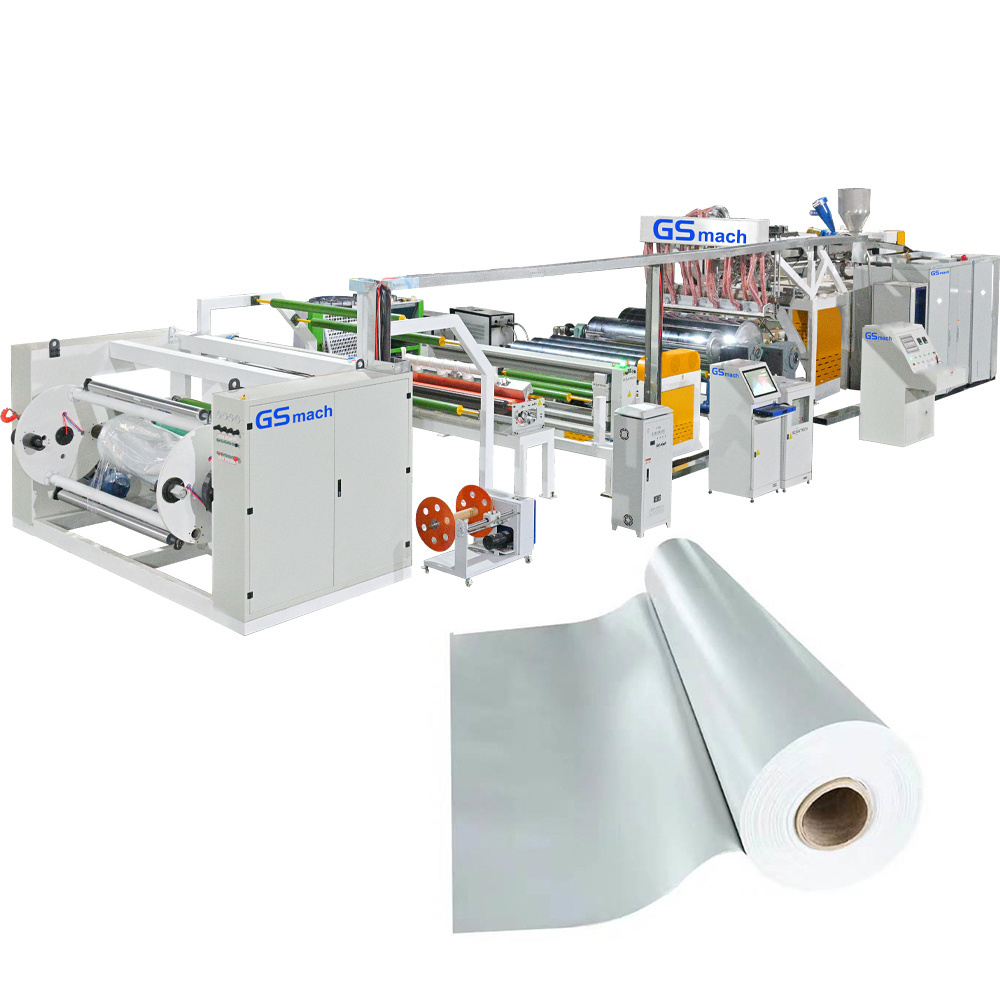

pe cast film machine stretch film production line

-

Model:

-

1600

-

Product width:

-

800~1800

-

Product thickness:

-

1~3mm

-

Max speed:

-

3~10m

-

Automatic Grade:

-

Full-automatical

-

Power:

-

150kw

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

32

-

Screw diameter (mm):

-

150

-

Screw Speed (rpm):

-

60 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GS-mach

-

Voltage:

-

380V/3P

-

Dimension(L*W*H):

-

25*4.5*6.5

-

Power (kW):

-

110

-

Weight:

-

25 KG

-

Raw material:

-

PE PP PS PC ABS PMMA PET PLA PVDF

-

name:

-

pe cast film machine stretch film production line

-

Model:

-

1600

-

Product width:

-

800~1800

-

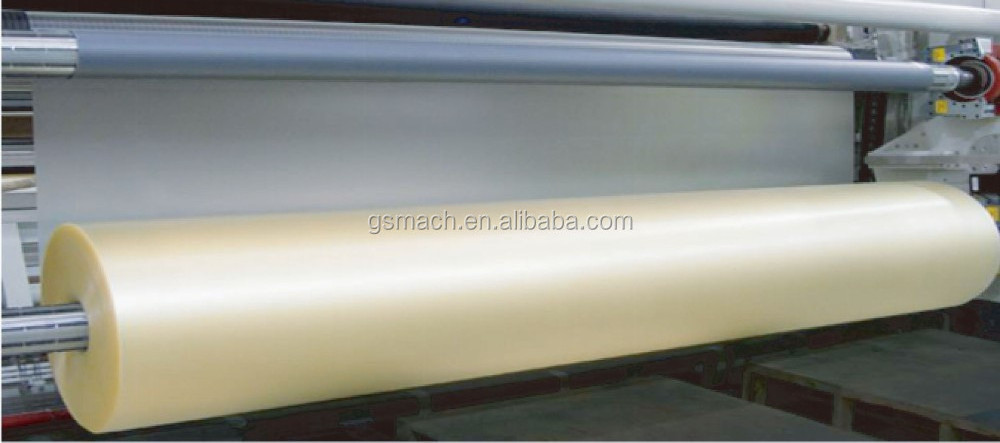

Product thickness:

-

1~3mm

-

Max speed:

-

3~10m

-

Automatic Grade:

-

Full-automatical

-

Power:

-

150kw

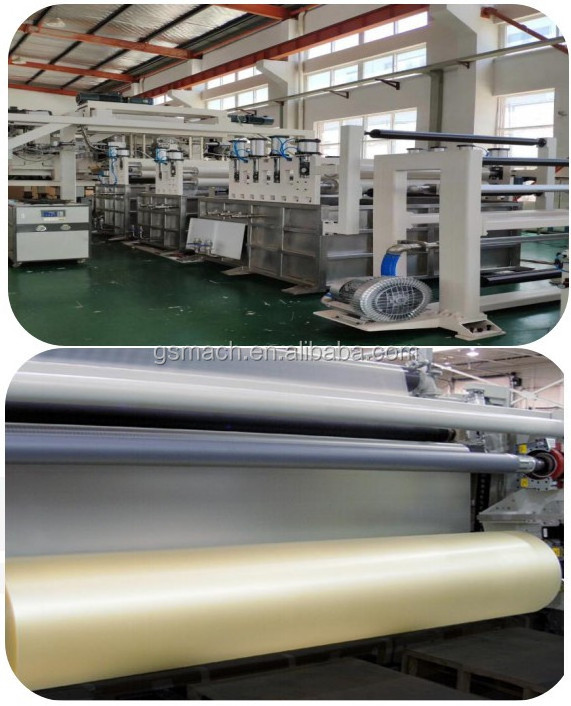

Car floor lamination glass lamination film tablet film coating machine

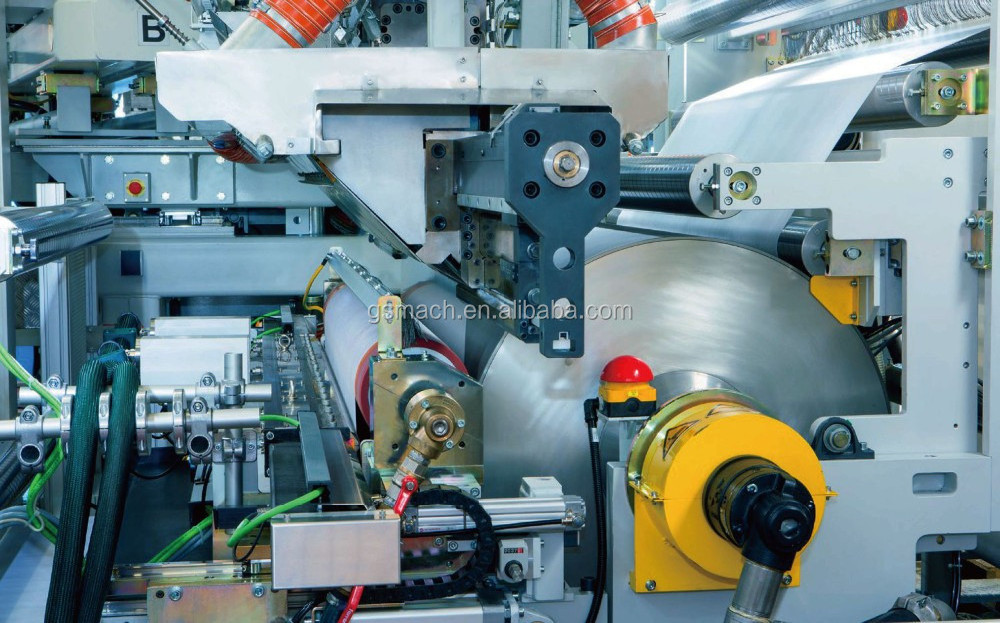

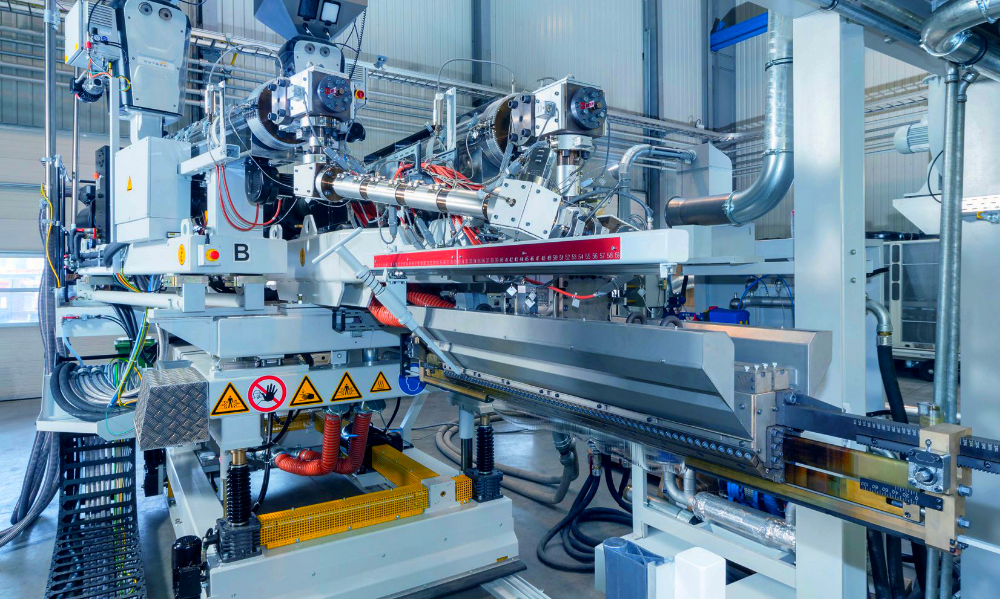

The equipment adopts single-screw design, equipped with weighing and batching system, central proportional control, automatic supply alarm for lack of material, and the products are cooled by soft water.Clear product, less fine particles, equipped with heat treatment oven, effectively remove stress, equipped with on-line thickness gauge device, trimming device, winding using friction winding method Constant tension control, production acceleration and deceleration can be synchronized ratio control, the speed can reach 10m\min_20m\min

Process principle:

After the PVB powder is put into the automatic mixing system → into the extruder, melt plasticization → rapid filter → metering pump → hanger mold→ Water-passing molding table → Water catching device → Heat-treating oven device → X-ray thickness gauge → Air cooling device → Traction device → Winding device

|

Equipment model

|

1600/2000

|

|

Product width (mm)

|

1400/1800

|

|

Product thickness (mm)

|

0.1-1.5mm

|

|

Maximum line speed (m/min)

|

10-20m

|