- Product Details

- {{item.text}}

Quick Details

-

Power:

-

110 kw

-

Dimension(L*W*H):

-

20*2*4 m

-

Weight:

-

2000 KG

-

Marketing Type:

-

New Product

-

Key Selling Point:

-

Full automatic

-

Machine materials:

-

Stainless Steel

-

Heating way:

-

Electric, gas, diesel, steam

-

Sales service:

-

Machine Installation and Commissioning, Online

-

Raw material:

-

Grain powder, nutrients, etc.

-

Capacity:

-

100 kg/h-300 kg/h

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SBN

-

Voltage:

-

220/440/380V custom

-

Power:

-

110 kw

-

Dimension(L*W*H):

-

20*2*4 m

-

Weight:

-

2000 KG

-

Marketing Type:

-

New Product

-

Key Selling Point:

-

Full automatic

-

Machine materials:

-

Stainless Steel

-

Heating way:

-

Electric, gas, diesel, steam

-

Sales service:

-

Machine Installation and Commissioning, Online

-

Raw material:

-

Grain powder, nutrients, etc.

-

Capacity:

-

100 kg/h-300 kg/h

300 kg/h pasta production machines spaghetti machine

Products Description

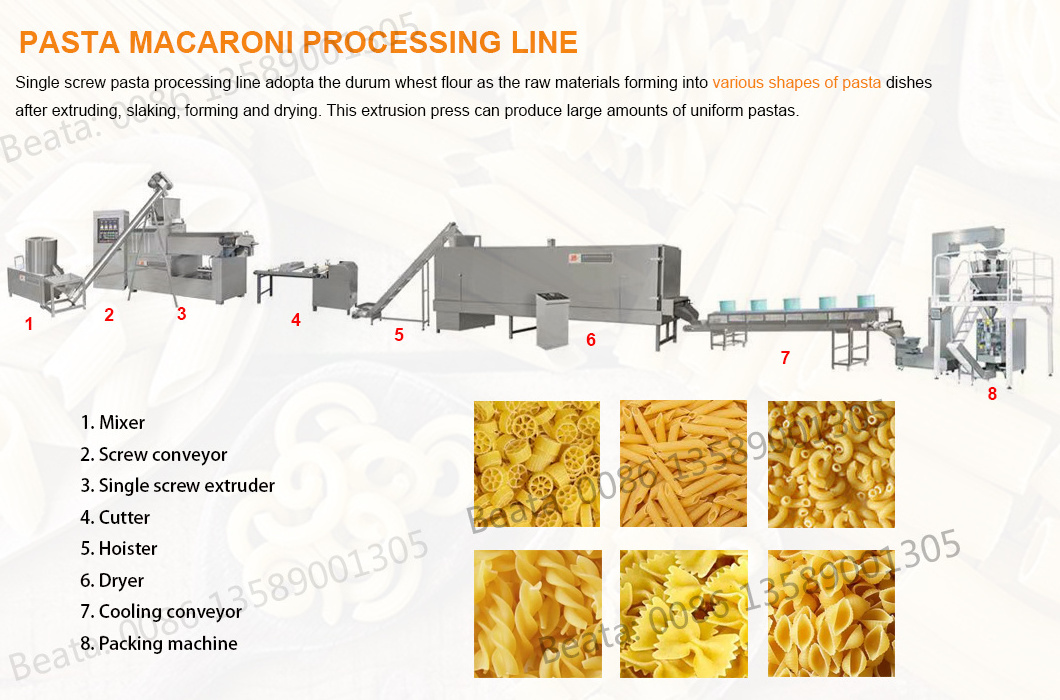

The main function

1). Function: The main raw material is "Durum wheat" (hard wheat) with a high enough protein content, through a high temperature and high pressure extrusion system, and then through a rotary cutting system, a drying system, and a packaging system to produce pasta/macaroni.

2). Raw material : Semolina,wheat flour,corn flour,potato starch,corn starch etc.

3). Final food : different shapes and sizes of pasta.

4). Capacity: 100-150 kg/h,250 -300k/h.

Requirements

1). Consumption : Low electricity and labor consumption

2). Design: With flexible design based on the client's demands, we provide turn key project.

3). Grade : SUS201,SUS304

5). Dryer oven heating way: Electricity, steam, gas, oil.

1). Function: The main raw material is "Durum wheat" (hard wheat) with a high enough protein content, through a high temperature and high pressure extrusion system, and then through a rotary cutting system, a drying system, and a packaging system to produce pasta/macaroni.

2). Raw material : Semolina,wheat flour,corn flour,potato starch,corn starch etc.

3). Final food : different shapes and sizes of pasta.

4). Capacity: 100-150 kg/h,250 -300k/h.

Requirements

1). Consumption : Low electricity and labor consumption

2). Design: With flexible design based on the client's demands, we provide turn key project.

3). Grade : SUS201,SUS304

5). Dryer oven heating way: Electricity, steam, gas, oil.

Details Images

Processing line

1).

100 -150 kg/h

: Mixer--Screw conveyor--Single screw extruder--Conveyor cutter--Hoister--Dryer--Cooling Conveyor--Packing Machine

2).

250-300 kg/h

: Mixer--Screw conveyor--Single screw extruder--Conveyor cutter--Hoister--Dryer--Hoister--Dryer--Cooling

Conveyor--Packing Machine

Conveyor--Packing Machine

Molds and samples

This line can change the mold to produce different shapes of pasta /macaroni. We will give you 4 sets of molds for each production line.

Layout

We can draw the layout according to the size of the customer's factory, and also plan the layout of each area before the factory is built.

We can draw the layout according to the size of the customer's factory, and also plan the layout of each area before the factory is built.

Advantage

Macaroni making machine,Pasta forming machine , with perfect technology, compact structure, original design and stable

performance, is developed on the base of advanced products and requirements in the world market. It realizes high automation, convenient operation, low energy and small floor space, that assures all working procedures from feeding flour to finished products can be accomplished once. The pasta macaroni product produced by this line is tenacious smooth and transparent.

Machine Parameters

|

No.

|

Type

|

Capacity

|

Dimension

|

Total power (kw)

|

|

1

|

DLG-110

|

100-150 kg/h

|

19 m x 2 m x 4 m

|

118

|

|

2

|

DLG-150

|

50-300 kg/h

|

27 m x 2 m x 4 m

|

225

|

Why Choose Us

Accessories and materials

1.Frequency converter brand use LC. Electric parts use ABB or Schneider.

2.Siemens motor.

3.Machines Materials: All the machines are made by food grade stainless steel.

2.Siemens motor.

3.Machines Materials: All the machines are made by food grade stainless steel.

Customization and Quality

1. We can provide you with appropriate machine instruction according to your needs.

2. Voltage: three-phase 380V / 415V / 440V, etc., we can customize according to the local voltage of the country where the

customer is located.

3. Color etc. can also be customized.

2. Voltage: three-phase 380V / 415V / 440V, etc., we can customize according to the local voltage of the country where the

customer is located.

3. Color etc. can also be customized.

Our service and Ability

Pre-sale service

1.Provide customization: 15 years of customization experience can help you customize the machine according to your

needs according to output, site area and structure.

2. Project planning and design service.

3. Remote video test machine, and provide mailing service (postage at your own expense).

4. 24-hour online consulting service.

5. Live watch factory service.

After-sales service

1. Provide 1 year complete warranty and life-time maintenance service. Discount on spare parts purchase after one year. 2. 24-hour online guidance and commissioning service.

3. New production techniques and formulas.

4. Provide training services.

Staff and Ability

1. Our company has a complete team, including professional engineers, production workers, sales staff and after-sales service technicians.

2. Engineers with rich experience can help you achieve full-link professional services from customization to debugging guidance.

3. Excellent service capacity, has served customers in more than 100 countries around the world.

1. Our company has a complete team, including professional engineers, production workers, sales staff and after-sales service technicians.

2. Engineers with rich experience can help you achieve full-link professional services from customization to debugging guidance.

3. Excellent service capacity, has served customers in more than 100 countries around the world.

Packing and Delivery

1). Packing: inside plastic bag, outside wooden case for Machine(Based on the customers' need adopt the wooden case or wooden pellets, etc.).

2). Delivery Details : 30-60 days after order

2). Delivery Details : 30-60 days after order

Hot Searches