- Product Details

- {{item.text}}

Quick Details

-

Name:

-

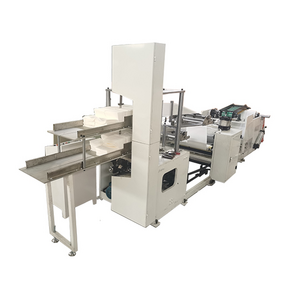

toilet tissue napkin paper rewinding converting folding machine

-

Model:

-

GM-AA

-

Working speed:

-

150-200m/min

-

Machine Material:

-

stainless steel,cast iron

-

Input:

-

jumbo roll paper

-

Output paper:

-

toilet paper small roll,facial tissue,napkin

-

Control method:

-

PLC

-

Folding size:

-

230*230mm(adjustable)

-

Experience:

-

32 years

Quick Details

-

Production Capacity:

-

16 tons per day

-

Place of Origin:

-

Henan, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Video technical support, Online support

-

Name:

-

toilet tissue napkin paper rewinding converting folding machine

-

Model:

-

GM-AA

-

Working speed:

-

150-200m/min

-

Machine Material:

-

stainless steel,cast iron

-

Input:

-

jumbo roll paper

-

Output paper:

-

toilet paper small roll,facial tissue,napkin

-

Control method:

-

PLC

-

Folding size:

-

230*230mm(adjustable)

-

Experience:

-

32 years

toilet paper rewinding machine,tissue paper converting machine,restaurant napkin folding machine

Contact Ms Bella 24 Hours Hotline:+86-18736029028

I.Function:

(1) It is mainly used to slit the single ply tissue and rewinded i nto one, two or three ply paper with desired width, for the production of toilet tissue paper , hankies , napkins , and facial tissue . this machine use vacuum suction to hold the paper, and the upper slitting knives are mounted in a fixed angle on the rolls, which can guarantee the stable running, nice and clear cutting edges , making it an ideal machine for paper mills and paper product making factories to slit and rewind jumbo rolls.

(2) The toilet tissue paper can be embossed with different flower pattern types by using the embossing rollers.

II.Main Features

(1)equipped with timing gear-box transmission;

(2)embossing roll can be heated by heating element automatically;

(3)various embossing style for consumer’s choice;

(4)work steadily ,low noise;

(5)easy to operate and maintain;

III.Main Technical Parameters:

|

name |

paperconverting machine |

|

model |

GM-AA |

|

Raw material diameter |

≤Φ1100mm |

|

folding size |

230×230mm(adjustable) |

|

Finished size |

230×230mm(adjustable) |

|

speed |

150-200m/min |

|

power |

5.5kw |

|

dimension |

2000×800×1600mm(L×W×H) |

|

weight |

960kg |

IV.Paper Rewinding Machine:

---of "toilet paper rewinding machine,tissue paper converting machine,restaurant napkin folding machine "

V.Embossing Patterns:

---of "toilet paper rewinding machine,tissue paper converting machine,restaurant napkin folding machine "

VI. Band Saw Cutter:

---of "toilet paper rewinding machine,tissue paper converting machine,restaurant napkin folding machine "

VII.Napkin Embossing & Folding Machine:

---of "toilet paper rewinding machine,tissue paper converting machine,restaurant napkin folding machine "

VIII.Paper Converting Process:

---of "toilet paper rewinding machine,tissue paper converting machine,restaurant napkin folding machine "

IX. Finished Product:

---of "toilet paper rewinding machine,tissue paper converting machine,restaurant napkin folding machine "

All machine parts is designed and manufactured according to the following paper industry standard:

1.Quality standard:

|

GB191 |

packaging and storing instructions Logo |

|

GB5799 |

dynamic balance of paper machine roller,cylinder and dryer |

|

GB6388 |

transport packaging ,sending-receiving logo |

|

JB8 |

product label |

|

JB1130 |

cylindrical gear reducer |

|

GB842 |

Light Industry Machinery, Weighing general technical conditions |

|

QBJ1—64 |

installation and inspection regulation for pulp and paper professional equipment |

|

ZBY9003 |

technical requirement for cast iron dryer of paper machinery |

2.dynamic grade of all roller is designed :G2.5 ;

3. Dynamic grade of dryer is designed :G4;

4.all the roller is chrome coating ;

5.electric control system : SIMENS ;

6.Bearing : china famous brand or SKF ;

7.Drive section : sealed gear box with lubrication system ;

(1) Packaging:

1. Products will be packaged according to their shapes, weight, transport distance and transport modes. Large machines will be packaged in sections. Every part of export machinery will be in standard export wooden package , waterproof film, straw rope, carton box ,etc, which will ensure the intactness of the products.

(2) Delivery:

1 sea transportation is from qingdao seaport or other ports.

2 the delivery time is decided by your needed machines or machine parts. But it also follows your needs.

A.Pre-Sale Service:

1. 24 hours phone,email,tradem anager online services;

2.we will supply the detailed project report ,detailed general drawing ,detailed flow process design ,detailed layout factory drawing for you until meet your requirement;

3.we welcome you to come to our paper making machine factory and paper mill factory to have a look and check;

4.we will tell you all the necessary cost when set up a paper mill factory;

5.we will answer you all the questions within 24hours;

6.we will send you various quality paper samples made by our paper machine for free;

7.We can supply turn key-project service.

B.On-purchase service:

1.we will accompany you to check all the equipments made by us,and help you to make the plan of installation;

2.we will supply paper machine assembly drawing , the foundation and foundation load diagram, transmission diagram,formal installation drawing, use and installationinstructions and a full set of technical data after signing the contract.

C.After-sales service:

1.we will delivery the machine as soon as possible according to your requirement ,within 20days;

2.We will send rich practiced experience engineers to you to install and test the machine and train your worker for free;

3.We will give you one year guarantee time after the machine can run well;

4.After one year,we can guide and help you to maintain the machines;

5. every 2 years, we can help to overhaul the complete machines for free;

6.we will send you spare part in lower price .