- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

PLASTAR

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

7.5*2.3*2.6M

-

Weight:

-

5000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Screw Diameter:

-

55/75/55mm

-

Screw material:

-

Bi-metallic(38CrMoALA)

-

Screw L/D:

-

30:1

-

Film width:

-

1500mm

-

Film Thickness:

-

0.008-0.05mm

-

Die head width:

-

1800mm

-

Output:

-

180kg/h

-

Usage:

-

Cling film; stretch film; pallet wrap film

-

Automatic Grade:

-

Automatic

Quick Details

-

Screw Design:

-

three screws

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

100 rpm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

PLASTAR

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

7.5*2.3*2.6M

-

Weight:

-

5000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Screw Diameter:

-

55/75/55mm

-

Screw material:

-

Bi-metallic(38CrMoALA)

-

Screw L/D:

-

30:1

-

Film width:

-

1500mm

-

Film Thickness:

-

0.008-0.05mm

-

Die head width:

-

1800mm

-

Output:

-

180kg/h

-

Usage:

-

Cling film; stretch film; pallet wrap film

-

Automatic Grade:

-

Automatic

Products Description

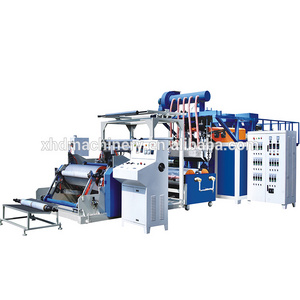

Shrink PE Film Making Machine

1. Introduction of Stretch Cling Film Machine:

Stretch cling film machine mainly use LLDPE,LDPE or recycled LLDPE material to produce one side sticky or 2 sides sticky stretch film,cling film.

1) Main parts: one electrical power control box,3 extruders, 1 die,2 cooling forming rollers,on-line recycling system,auto-cutting system,auto-winding system,2 winding shafts etc.

2) Layers to be produced: 3 layers(one side sticky or 2 sides sticky stretch film) or 5 layers

3) Heating power: Total power is 130 kw

4) Spare parts: All advanced spare parts are imported from Japan,Taiwan,China brand parts etc.

5) Width to be produced: min 200mm to max 1500mm

6) Thickness to be produced: 0.01mm-0.05mm

7) Auto carton loading&unloading system,no need to put air into the air shaft,and no adhensive tapes required(optional system)

2. Use:

1) The most usage pallet packaging: Such as fertile, cement, chemicalindustrial raw material, building material etc.

2) Horizontal packaging: Metal pipe, aluminum alloy material, timber etc.

3) Rotational twist: Rolling paper, carpet etc.

4) Binding: Glass container, acceptance etc.

5) Break-bulk packaging: Soybean, grain, plastic particle etc.

6) Storage packaging: Such as grass.

7) Manual packaging: It is used in wholesales, journal, printing, electronic product, foodstuff etc.

8) Ring twist packaging: Type, wire, cable, steel silk etc.

3. Finished Products:

It is a very good kind of packaging material mostly used in the industrial field,port pallet packaging,,building material

packaging, hardware packaging etc.It enjoys the following advantages:

1) Good tensile strength

2) Superior anti-pricking ability

3) High transparency

4) Good ductility and anti-impact strength

5) Stable sticky sides etc

4. Features:

1) Higher output with stable quality stretch film,superior than the same suppliers more than 30%.

2) Higher speed with good ideal tensil and anti-pricking stretch film, which make sure the machine make big output.

3) Good water cooling effect and imported die steel to ensure making even and good ductility stretch film.

4) Swing system installed to adjust the film thickness and evenness.

5) The alloy screw adopts special mixing function and high plasticizing design which combine import static mixer to ensure

plasticization is great, color is uniform and increase extrusion capacity greatly.

6) PLC controlled,fully automatic.

Stretch cling film machine mainly use LLDPE,LDPE or recycled LLDPE material to produce one side sticky or 2 sides sticky stretch film,cling film.

1) Main parts: one electrical power control box,3 extruders, 1 die,2 cooling forming rollers,on-line recycling system,auto-cutting system,auto-winding system,2 winding shafts etc.

2) Layers to be produced: 3 layers(one side sticky or 2 sides sticky stretch film) or 5 layers

3) Heating power: Total power is 130 kw

4) Spare parts: All advanced spare parts are imported from Japan,Taiwan,China brand parts etc.

5) Width to be produced: min 200mm to max 1500mm

6) Thickness to be produced: 0.01mm-0.05mm

7) Auto carton loading&unloading system,no need to put air into the air shaft,and no adhensive tapes required(optional system)

2. Use:

1) The most usage pallet packaging: Such as fertile, cement, chemicalindustrial raw material, building material etc.

2) Horizontal packaging: Metal pipe, aluminum alloy material, timber etc.

3) Rotational twist: Rolling paper, carpet etc.

4) Binding: Glass container, acceptance etc.

5) Break-bulk packaging: Soybean, grain, plastic particle etc.

6) Storage packaging: Such as grass.

7) Manual packaging: It is used in wholesales, journal, printing, electronic product, foodstuff etc.

8) Ring twist packaging: Type, wire, cable, steel silk etc.

3. Finished Products:

It is a very good kind of packaging material mostly used in the industrial field,port pallet packaging,,building material

packaging, hardware packaging etc.It enjoys the following advantages:

1) Good tensile strength

2) Superior anti-pricking ability

3) High transparency

4) Good ductility and anti-impact strength

5) Stable sticky sides etc

4. Features:

1) Higher output with stable quality stretch film,superior than the same suppliers more than 30%.

2) Higher speed with good ideal tensil and anti-pricking stretch film, which make sure the machine make big output.

3) Good water cooling effect and imported die steel to ensure making even and good ductility stretch film.

4) Swing system installed to adjust the film thickness and evenness.

5) The alloy screw adopts special mixing function and high plasticizing design which combine import static mixer to ensure

plasticization is great, color is uniform and increase extrusion capacity greatly.

6) PLC controlled,fully automatic.

|

Item/Model

|

1250mmDouble-layer

|

1250mmSingle-layer

|

|

Screw diameter(mm)

|

65

|

75

|

|

L/D ratio of screw (L/D)

|

30:1

|

30:1

|

|

width of die head (mm)

|

1250

|

1250

|

|

Width of finished products(mm)

|

1000(500*2roll)

|

1000(500*2roll)

|

|

Thickness of finished products (mm)

|

0.017-0.05

|

0.017-0.05

|

|

Structure of film layers

|

A/B

|

--

|

|

Max output (kg/h)

|

100

|

100

|

|

Linear speed of machinery (m/min)

|

50-100

|

50-100

|

|

Total power (KW)

|

140

|

120

|

|

Overall dimensions (L*W*H)m

|

10*4*3

|

11*4.5*3

|

|

Weight (T)(About)

|

5.5

|

5.5

|

Hot Searches