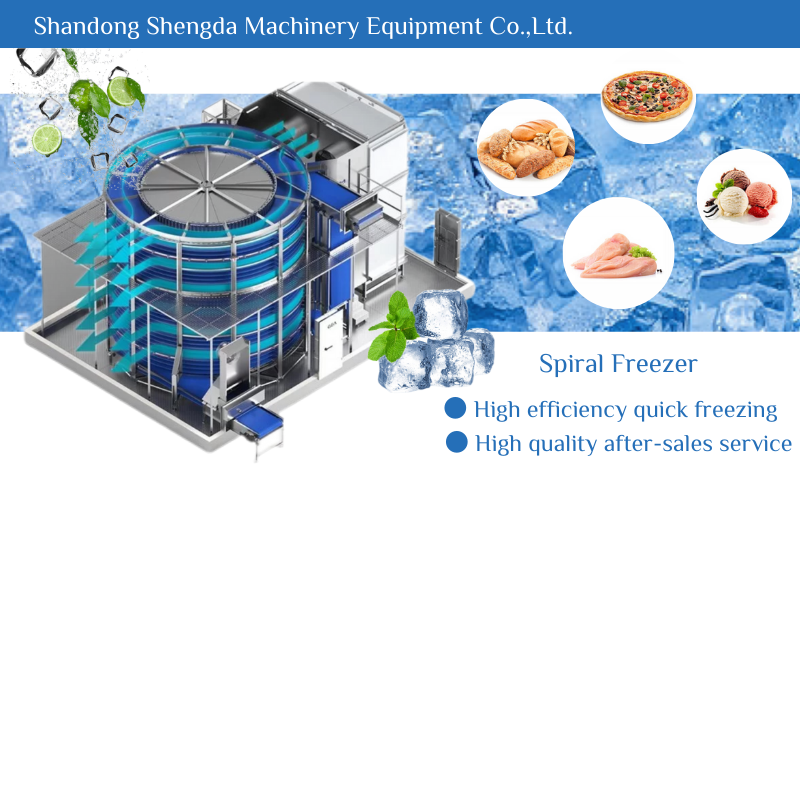

①Flexible

The compact offers flexible belt configurations in three different layouts, rotating clockwise or counter-clockwise and

upwards or downwards conveying. The number of tiers and clearance between the tiers can be adapted to the particular product and capacity.

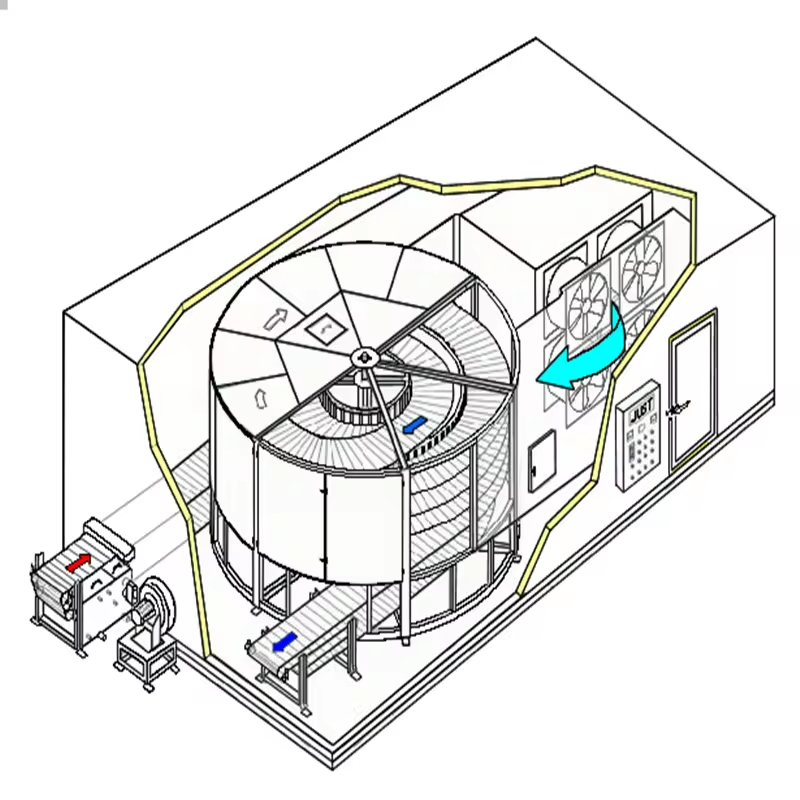

②Sophisticated

The wall and ceiling panels of the insulating enclosure are lined inside with stainless steel, while the floor

consists of a fully seam-welded stainless steel tray with defined drains. The unit can be accessed by means of two stainless steel doors in the insulating enclosure with contact switches and an electrical frame heating.

③Versatile

The conveyor system can accommodate a variety of different belts.Stainless steel or plastic belts, with open or closed

belt surface, with small or large pitches, and with or without side plates. The stainless steel and plastic belts can be retrofi

tted at a later date.

④Mobile

The compact comes fully assembled on a base frame. The system is ready for use as soon as the media, such as power,

refrigerant and water (for models with cleaning system only) have been connected. The base frame allows it to be moved from one

location to another quickly and easily.

⑤

Functional

Equipped with a mini PLC and a graphic multifunctional display, all of the system parameters can be set precisely.

Frequency-controlled main and auxiliary drives enable infi nitely variable regulation of the belt speed and, thus, the retention times.

⑥

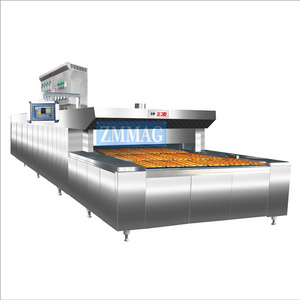

Adaptable

Whether equipped with a loading conveyor for the transfer of form sensitive products onto the already collapsed belt, a

horizontal infeed conveyor for safe delivery at the infeed or a discharge conveyor for the downstream system – the arctic adapts perfectly to every layout.

⑦

Efficient Every compact can be defrosted with fan-driven air once the refrigerant has been switched off. Furthermore, the defrosting process can be enhanced and carried out more effi ciently by means of hot gas or electrical heat.