- Product Details

- {{item.text}}

Quick Details

-

Warranty of core components:

-

1 Year used sand dredger pump

-

Dredging Depth:

-

7 m

-

Draught:

-

100 cm

-

Place of Origin:

-

china dredge pump

-

Brand Name:

-

An Pump mud dredg pump

-

Dimension(L*W*H):

-

1.3x1.2x1.4m

-

Weight:

-

3500 KG

-

Medium:

-

Sand suction gravel pumps

-

Use for:

-

River sand pump dredger

-

Size:

-

As need like 12 inch dredge pump

-

Project:

-

Sand pumping machine

-

Sand dredge pump use in:

-

18inch Cutter suction dredger

-

Conditions:

-

Dredge booster pump

-

Working on:

-

Pump sand transportation barge

-

Pump type:

-

Sand and gravel pump Cheap prices of dredger

-

Application:

-

Cutter suction dredger Machine

Quick Details

-

Video outgoing-inspection:

-

sand pebble pump Provided

-

Machinery Test Report:

-

Provided 3 inch sand pump diesel engine

-

Marketing Type:

-

Hot Product 2019 3 inch sand pump diesel engine

-

Warranty of core components:

-

1 Year used sand dredger pump

-

Dredging Depth:

-

7 m

-

Draught:

-

100 cm

-

Place of Origin:

-

china dredge pump

-

Brand Name:

-

An Pump mud dredg pump

-

Dimension(L*W*H):

-

1.3x1.2x1.4m

-

Weight:

-

3500 KG

-

Medium:

-

Sand suction gravel pumps

-

Use for:

-

River sand pump dredger

-

Size:

-

As need like 12 inch dredge pump

-

Project:

-

Sand pumping machine

-

Sand dredge pump use in:

-

18inch Cutter suction dredger

-

Conditions:

-

Dredge booster pump

-

Working on:

-

Pump sand transportation barge

-

Pump type:

-

Sand and gravel pump Cheap prices of dredger

-

Application:

-

Cutter suction dredger Machine

Diesel engine sand dredger pump for gravel

General:

Diesel engine sand dredger pump for gravel (ISO9001)1.Horizontal centrifugal Sand Gravel PumpSize (discharge): 1" to 18" (25 mm - 450 mm)

|

|

Detailed specification:

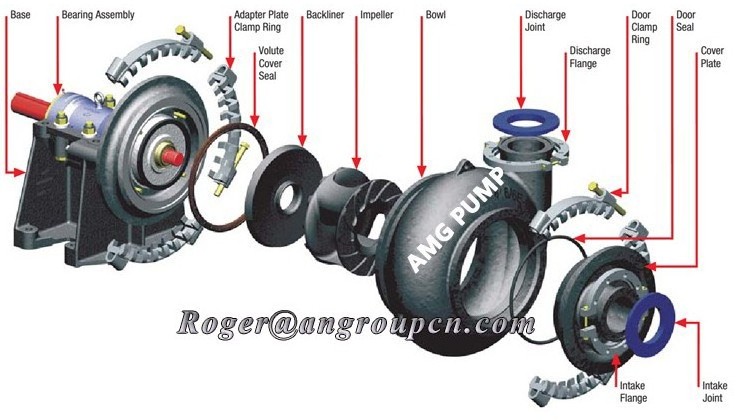

1. Horizontal, cantilevered, centrifugal, single stage slurry pump

2.Long bearing life: The bearing assembly is with large diameter shaft and short overhang.

3. Wear resistant and anti-abrasion wet parts: A05, A07, A33, A49 and rubber etc. They are completely interchangeable with each other

4. Easily replaceable liners, Liners are bolted to the casing.

5. Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing.

6 Discharge direction can be positioned at intervals of 360 degrees.

7. Simple maintenance throat-bush: the mating face of the throat bush is tapered, so the wear is reduced and removal is simple.

8. Sealing type: pcking seal,impeller sealing and mechanical seal.

9. Widely application: They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industrial departments.

10.Certification:ISO,CE

11.Welcome OEM new pump no 10inch fairly used sand dredging pump

Pump constructure

Performance parameters

|

Pump Model |

AMG Series Gravel Pump |

Impeller |

|||||

|

Allowable |

Clear Water Performance |

Dia.

|

|||||

|

Max.Power

|

Capacity Q |

Head |

Speed |

Eff. |

NPSH |

||

|

m 3 /h |

H(m) |

n(r/min) |

η% |

(m) |

|||

|

6/4AMG |

60 |

36-250 |

5-52 |

600-1400 |

58 |

2.5-3.5 |

378 |

|

8/6AMG |

120 |

126-576 |

6-45 |

800-1400 |

60 |

3-4.5 |

378 |

|

10/8AMG |

560 |

216-936 |

8-52 |

500-1000 |

65 |

3-7.5 |

533 |

|

10/8AMG |

560 |

180-1440 |

24-80 |

500-950 |

72 |

2.5-5 |

711 |

|

12/10AMG |

600 |

360-1440 |

10-60 |

400-850 |

65 |

1.5-4.5 |

667 |

|

12/10AMG |

1200 |

288-2808 |

16-80 |

350-700 |

73 |

2-10 |

950 |

|

14/12AMG |

1200 |

576-3024 |

8-70 |

300-700 |

68 |

2-8 |

864 |

|

14/12AMG |

600 |

720-3600 |

18-44 |

300-500 |

70 |

3-9 |

1016 |

|

16/14AMG |

1200 |

324-3600 |

26-70 |

300-500 |

72 |

3-6 |

1270 |

|

18/16AMG |

1200 |

720-4320 |

12-48 |

250-500 |

72 |

3-6 |

1067 |

|

20/18AMG |

1200 |

1080-5400 |

18-65 |

200-400 |

68 |

3-6 |

1270 |

Advantages

Pecial impellers designed to prevent damage when delivery solids sand suction dredge pump

The impeller and volute made of high chrome alloy

Specialized Test Equipment

Anti-rust treatment casting

CE, ISO, SGS certification

Application

(1). Absorb the sand in the river, lake and sea.

(2) .Absorb the silt and sand in the river, lake, sea, reservoir, pound, electric power plant .

(3). Absorb the slurry of stone processing plant.

(4). Absorb the slurry in the deep well.

(5). Absord and delivery extremely abrasive slurries

(6). Absord and continue delivery extremely corrosive liquid

More Product Photo:

|

|

An Pump Machinery Company to Customers:

1)Quality first. We guaranteed every part of the pump must be inspected closely

2)We can help you select suitable pump model according to your working condition and requirements.

3)We can design the related base or engine for your pumps.

4)Fast delivery time, large quantity of spare parts in stock .

1. Q: Are you a factory or trading company?

A: We are the manufacturer, we have designing, manufacturing, sales department, for manufacturing department, we opened casting, machinery, assembly, quality control and testing workshops. You are welcomed to come and visit our factory.

2. Q: Could you please introduce the travel line to your FACTORY ?

A: Yes, Line 1: Please first fly to Beijing international airport, and we will waiting you in the airport.

Line 2: If you are fly to Shanghai, then please take a Fast train to Shijiazhuang Station. Then we will meet you there.

Or connect with Roger Chen (Roger(a)angroupcn.com or call +86-13780512387) to confirm please.

3. Q: Is it available for OEM service?

A: Yes, it is no problem. We can accept OEM(original equipment manufacturer), processing with supplied drawings, materials, or samples.

4 Q: Is there any after-sales service ?

A: Yes, we can arrange our engineer to go to your application site for assembly or maintenance. PLEASE CHECK BELOW OUR AFTER-SALES SERVICE DETAILS

5 Q: Will have operation manual when shipping the products?

A: Yes, we will send you the operation manual together with the products.